Paint spraying wastewater treatment device

A wastewater treatment and oxidation device technology, applied in the direction of light water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve serious diseases, high fat solubility, endocrine disorders and other problems, and achieve the degree of automation High, easy to use, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

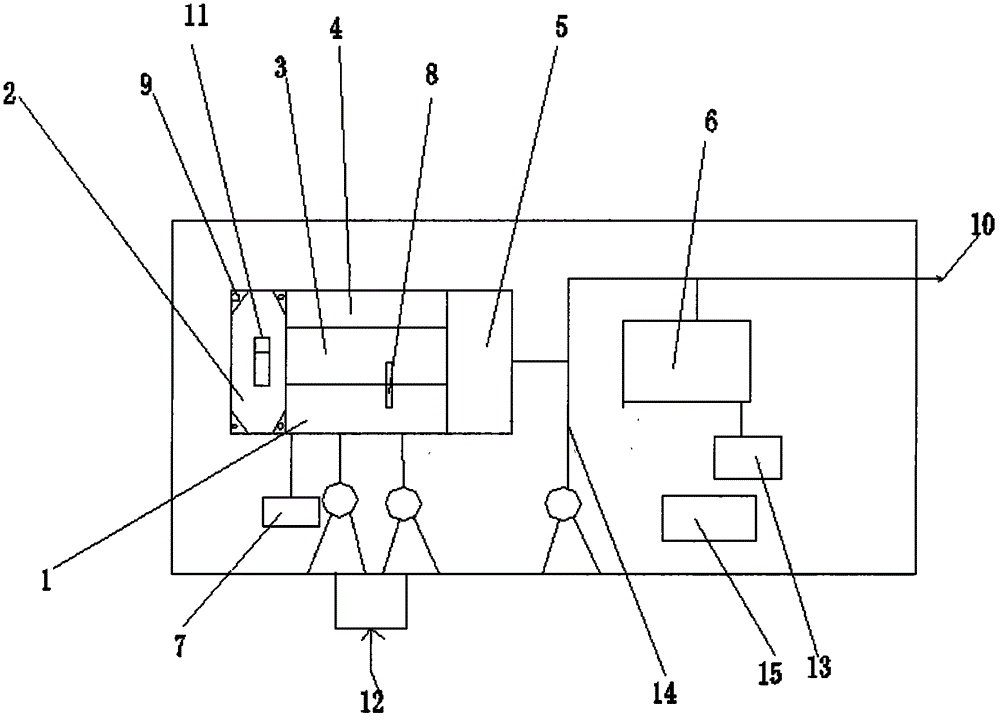

[0012] Such as figure 1 Shown, a kind of spray paint wastewater treatment device, comprises automatic control system 15, water pump system 14, dosing device 7 and the pretreatment pond 1 that is connected successively, oxidation device 2, reaction pond 3, coagulation flocculation pond 4, sedimentation pond 5 and The filter press device 6, the automatic control system 15 is provided with an industrial control PLC chip as the core part of the equipment, and the PLC chip carries out fully automatic control of electrical appliances such as water pumps in the equipment, reduces the unstable factors of manual control, and makes the effluent water quality stable. The pretreatment tank 1, the oxidation device 2, the reaction tank 3, the coagulation flocculation tank 4, the sedimentation tank 5, the filter press device 6, the water pump system 14 are electrically connected with the automatic control system 15 to realize automatic control, and the pretreatment tank 1 and reaction tank 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com