Microbial electrolytic cell and method for treating wood vinegar liquid by using same

A technology of microbial electrolysis cell and wood vinegar, which is applied in the field of biorefractory pyrolysis waste liquid treatment, can solve the problems of human health hazards, waste of nutrients, toxic and harmful, etc., and achieves high economy, efficient treatment, and high degradation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

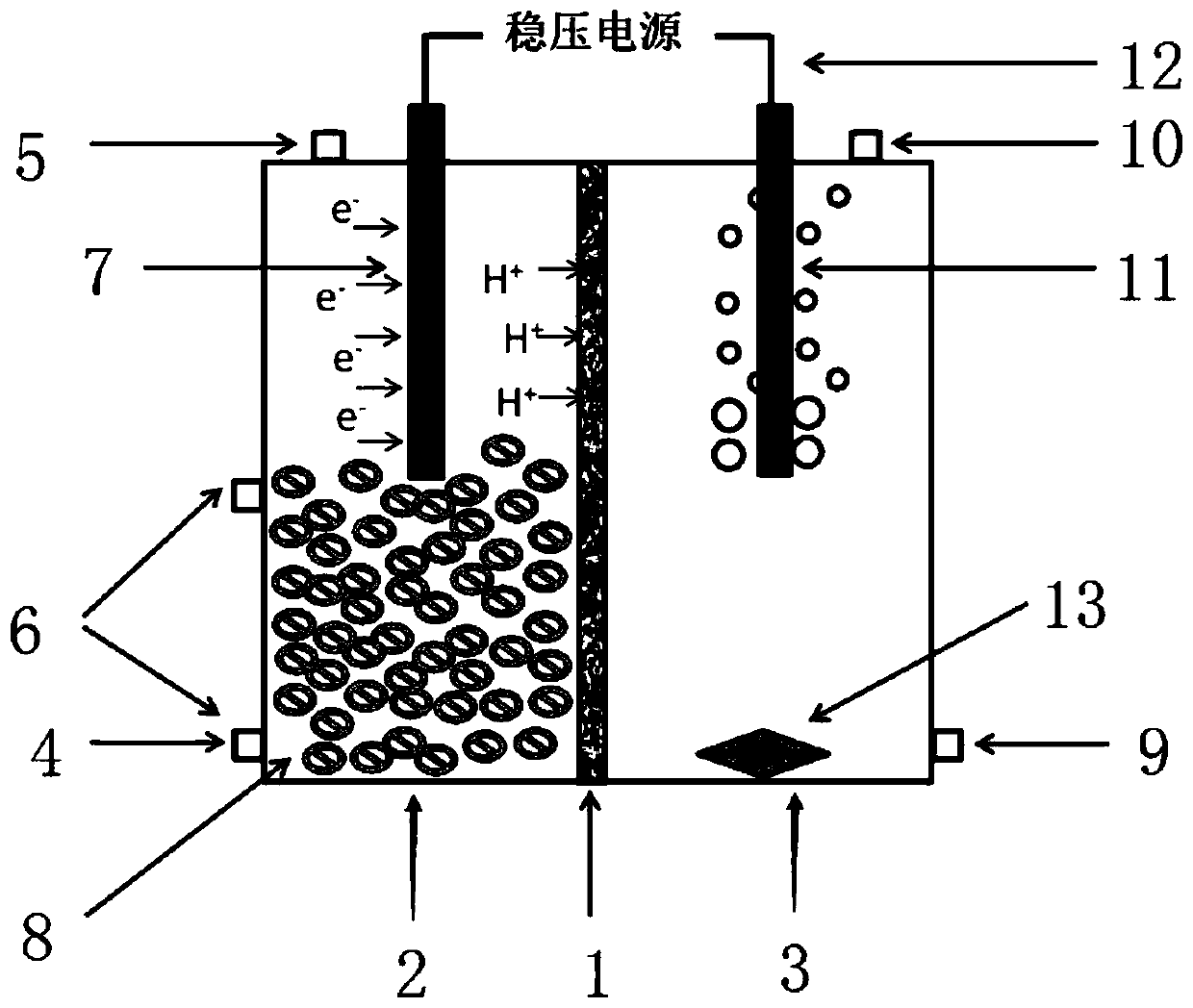

[0039] A method for treating wood vinegar in a coconut shell biochar anode microbial electrolytic cell includes the following steps:

[0040] (1) Pass the coconut shell biochar through a sieve (8-10 mesh), wash it with tap water for at least 3 times to remove the floating dust and charcoal on the surface, and then soak it in alcohol overnight to kill the existing microorganisms. After adding PBS to the cathode compartment of the microbial electrolytic cell, nitrogen was exposed to it for 20 minutes to remove dissolved oxygen.

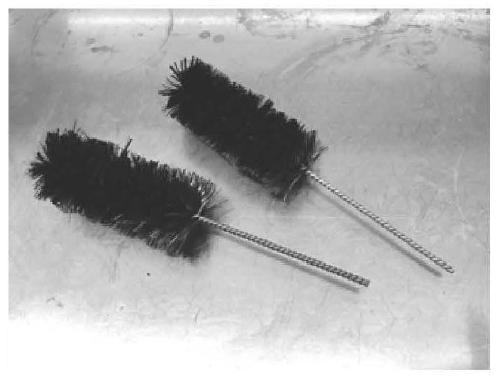

[0041] (2) The filling density of coconut shell biochar is two-thirds of the volume of the anode chamber, and the carbon fiber brush is inserted in the center of the coconut shell biochar to collect current. After the filling of the reactor is completed, the air-tightness test is carried out, and the leak is detected by the water injection method. The inside of the reactor is filled with water and the cover is sealed. The residence time is 2 days. Regularly ...

Embodiment 2

[0045] A method for treating wood vinegar in a bush biochar anode microbial electrolytic cell includes the following steps:

[0046] (1) Sieving the bush biochar (8-10 mesh), washing it with tap water for at least 3 times to remove the floating dust and charcoal on the surface, and soaking it with alcohol overnight to kill the existing microorganisms. After adding PBS to the cathode compartment of the microbial electrolytic cell, nitrogen was exposed to it for 20 minutes to remove dissolved oxygen.

[0047] (2) The packing density of bush biochar is two-thirds of the volume of the anode chamber, and the carbon fiber brush is inserted in the center of bush biochar to collect current. After the filling of the reactor is completed, the air-tightness test is carried out, and the leak is detected by the water injection method. The inside of the reactor is filled with water and the cover is sealed. The residence time is 2 days. Regularly observe the change of the liquid level. If the liq...

Embodiment 3

[0051] A method for treating wood vinegar liquid by a straw biochar anode microbial electrolytic cell includes the following steps:

[0052] (1) Pass the straw biochar through a sieve (8-10 mesh), wash it with tap water for at least 3 times to remove the floating dust and charcoal on the surface, and then soak it with alcohol overnight to kill the existing microorganisms. After adding PBS to the cathode compartment of the microbial electrolytic cell, nitrogen was exposed to it for 20 minutes to remove dissolved oxygen.

[0053] (2) The filling density of the straw biochar is two-thirds of the volume of the anode chamber, and the carbon fiber brush is inserted in the center of the straw biochar to collect current. After the filling of the reactor is completed, the air-tightness test is carried out, and the leak is detected by the water injection method. The inside of the reactor is filled with water and the cover is sealed. The residence time is 2 days. Regularly observe the change ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com