Water-based adhesive prepared by adding filler, and preparation method thereof

A filler and adhesive technology, which is applied in the field of water-based adhesives and its preparation, can solve the problems of low glue application, uneven glue application, and difficulty in meeting design requirements, and achieves the effect of realizing environmental protection discharge and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

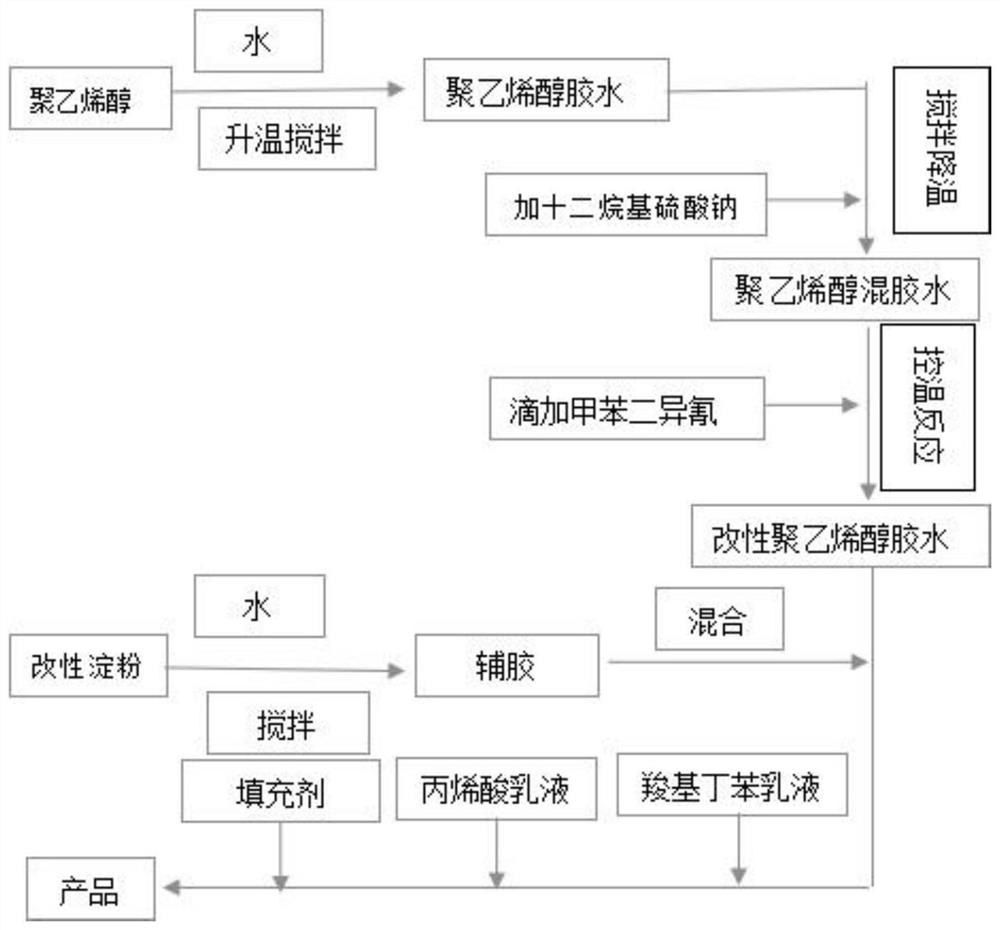

[0033] Embodiment 1, as figure 1 Shown, a kind of preparation method by adding the aqueous adhesive of filler, it comprises the steps:

[0034] Step 1. According to the ratio of parts by mass, add 7 parts of polyvinyl alcohol and 750 parts of water into the stirred reactor, raise the temperature in the stirred reactor to 95 degrees and then stir, and keep warm for half an hour after stirring to obtain polyvinyl alcohol. Vinyl glue;

[0035] Step 2. Stir the polyvinyl alcohol glue obtained in step 1 to cool down to 32 degrees, and add 1 part of sodium lauryl sulfate during the stirring process to obtain polyvinyl alcohol mixed glue;

[0036] Step 3. Add 14 parts of toluene diisocyanate dropwise to the polyvinyl alcohol mixed glue obtained in step 2, and then carry out stirring and temperature control reaction after adding the toluene diisocyanate dropwise, and obtain the modified polyvinyl alcohol glue after stirring evenly;

[0037] Step 4, adding 10 parts of modified starch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com