Method for purifying process condensate produced during application of catalytic dehydrogenation of ethyl benzene to produce styrene

A technology for ethylbenzene catalytic dehydrogenation production and process condensate, which is applied in chemical instruments and methods, degassed water/sewage treatment, neutralized water/sewage treatment, etc., and can solve the problem of high cost of iron removal and hydrocarbon removal. , did not consider the reduction of metal oxides or hydrocarbons, blockage of subsequent treatment systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

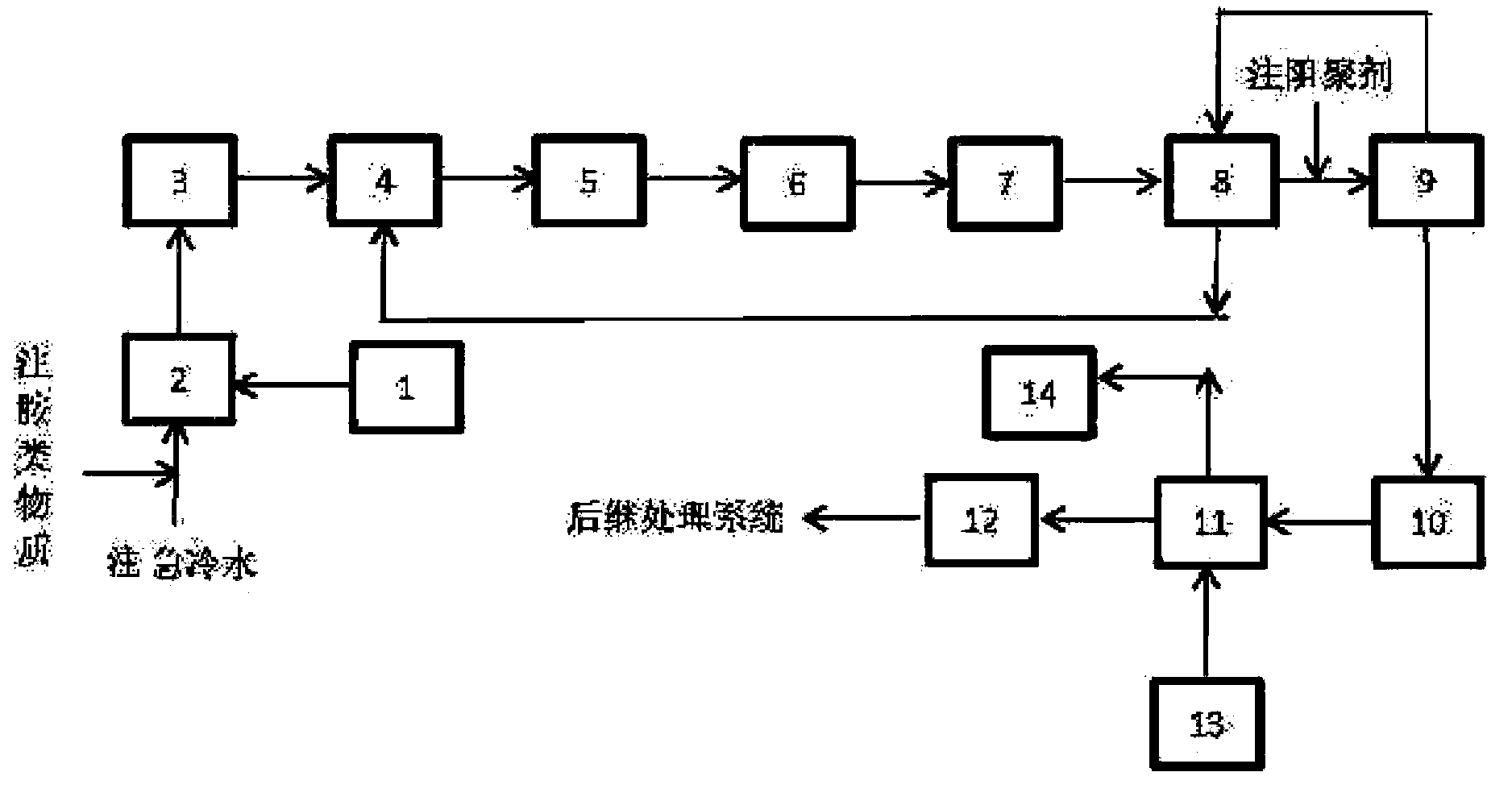

Method used

Image

Examples

Embodiment 1

[0030] In a styrene plant with an annual output of 120,000 tons, the amount of condensate in the process is 30-50t / h, and the amine substance added is N-methyldiethanolamine, and the amount added is 15ppm (the standard amount is acidic dehydrogenation liquid); The preferred polymerization inhibitor is diethylhydroxylamine, the amount added is 15ppm (the standard amount is the process condensate), the gas-water ratio of the stripping tower is 1000, and the temperature of the stripping gas is increased by 32.5°C after passing through the steam superheating furnace. The content of suspended solids is 4 mg / L, the total content of iron is 0.5 mg / L, and the total content of hydrocarbons is 10 mg / L.

Embodiment 2

[0032] A styrene plant with an annual output of 120,000 tons produces 30-50t / h of process condensate, and the added amine is ethylenediamine, and the added amount is 35ppm (the standard amount is acidic dehydrogenation liquid); The polymerization agent is N, 2-dihydroxy-N-(2-hydroxypropane) propylamine, the amount added is 15ppm (the standard amount is the process condensate), the gas-water ratio of the stripping tower is 500, and the stripping gas is superheated by steam The temperature behind the furnace increased by 65°C, the content of suspended solids in the effluent water was 2 mg / L, the total content of iron was 0.3 mg / L, and the total content of hydrocarbons was 9.0 mg / L.

Embodiment 3

[0034] In a styrene plant with an annual output of 120,000 tons, the amount of condensate produced in the process is 30-50t / h, and the amine substance added is methoxypropylamine, and the amount added is 20ppm (the standard amount is acidic dehydrogenation liquid); The polymerization inhibitor used is sodium nitrite, the amount added is 40ppm (the standard amount is the process condensate), the gas-water ratio of the stripping tower is 1200, the temperature of the stripping gas is increased by 27°C after passing through the steam superheating furnace, and the quality of the effluent is The content of suspended solids is 2 mg / L, the total content of iron is 0.3 mg / L, and the total content of hydrocarbons is 7.0 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com