Device for purifying, treating and utilizing combustion furnace tail gas

A tail gas purification and combustion furnace technology, which is applied in the direction of combustion product treatment, combustion method, combined device, etc., can solve the problems of low heat transfer efficiency, poor purification effect of combustion furnace tail gas, unsatisfactory tail gas heat recovery effect, etc. High thermal efficiency, realize the effect of environmental protection emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

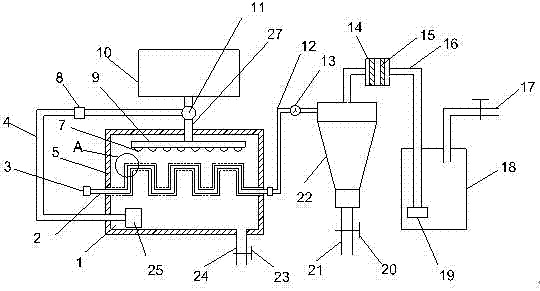

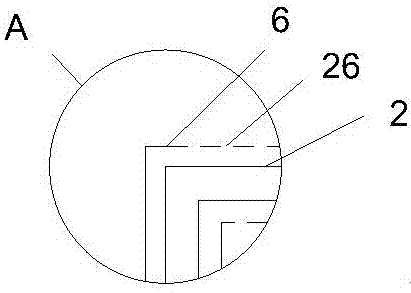

[0018] see Figure 1-2 , a combustion furnace tail gas purification treatment utilization device, including a heat exchange chamber 1, characterized in that, the bottom of the heat exchange chamber 1 is provided with a hot water pipe 24, the hot water pipe 24 is installed with a second gate valve 23; the heat exchange chamber 1 The outer surface is covered with thermal insulation cotton 5, and the heat exchange chamber 1 is provided with a curved serpentine pipe 2, and the left end of the serpentine pipe 2 is provided with an air inlet 3, and the air inlet 3 is located outside the heat exchange chamber 1; A casing 6 is provided on the outside of the shaped tube 2, and several heat exchange leakage holes 26 are evenly opened on the surface of the casing 6. A water distribution tray 9 is arranged in the heat exchange chamber 1, and a plurality of nozzles 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com