Advanced treatment device for printing and dyeing wastewater

A technology for advanced treatment, printing and dyeing wastewater, applied in multi-stage water treatment, water/sewage treatment, special compound water treatment, etc. The effect is remarkably stable, prolonging the service life, and ensuring the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

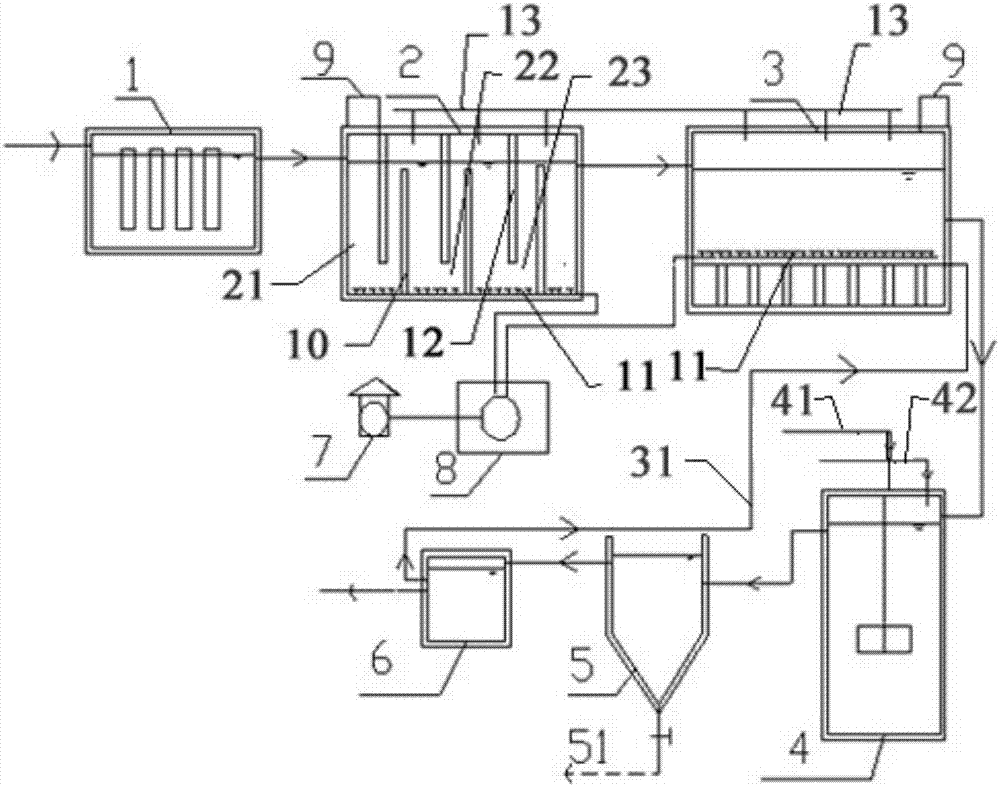

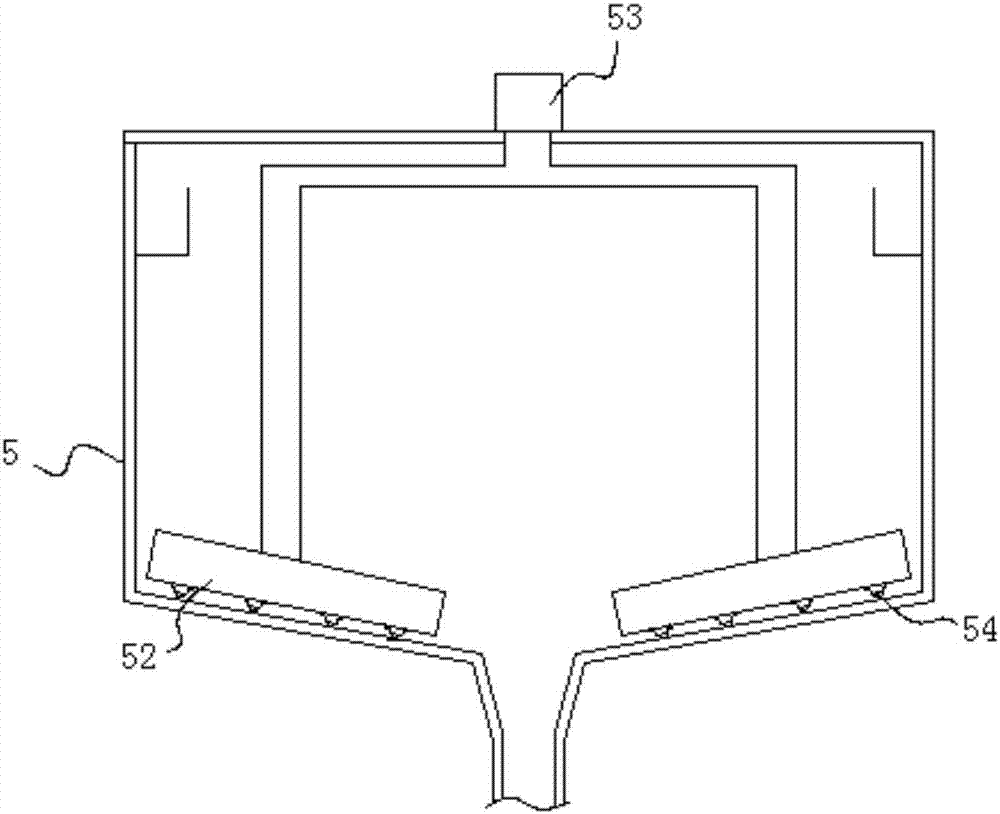

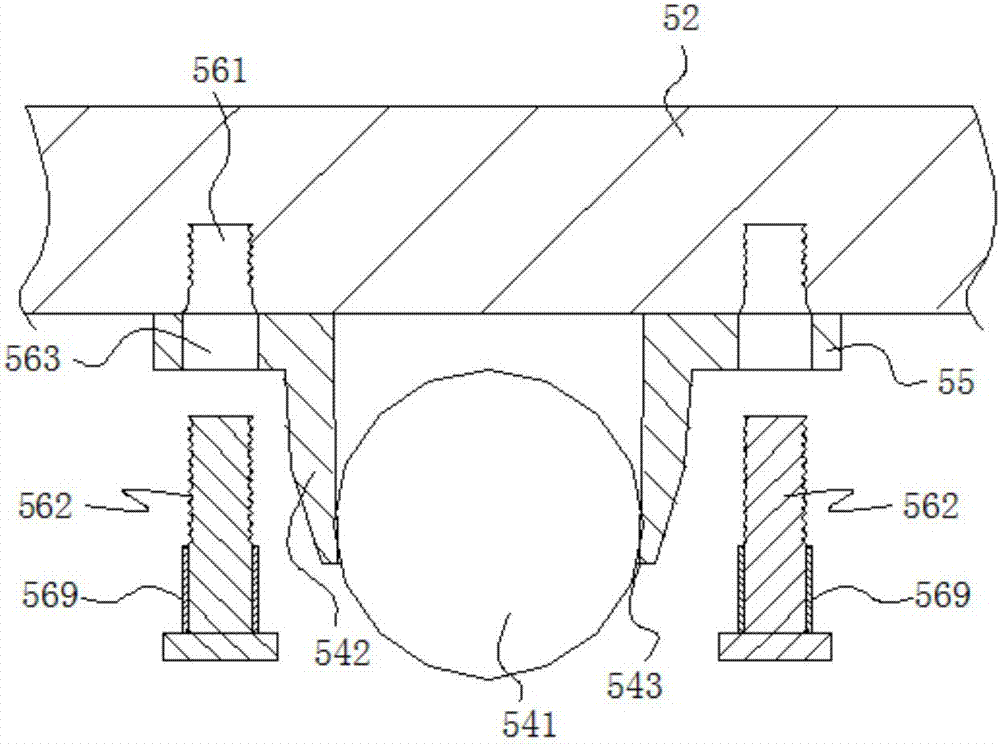

[0022] like Figure 1-3 As shown, an advanced treatment device for printing and dyeing wastewater includes a fiber turntable filter 1, an ozone contact tank 2, a filter 3, a reaction tank 4, a sedimentation tank 5 and a reservoir 6 connected in sequence, and the bottom of the sedimentation tank 5 is A sludge discharge pipe 51 is provided; the ozone contact tank is connected with an ozone generator 8, and the ozone generator is connected with an oxygen generator 7; specifically, the ozone generator 8 is an ozone generator, and the oxygen generator 7 is an oxygen generator. Generator: 3 extension plates 10 are distributed at intervals in the ozone contact pool 2, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com