Environment-friendly high-rise building public flue structure and flue cleaning system

A technology for high-rise buildings and public flues, used in building components, building structures, buildings, etc., can solve problems such as difficult cleaning, unfavorable smoke exhaust and fire prevention, and poor cleaning effects, and improve fire safety performance and structure. Reasonable and good effect of oil fume adsorption and interception function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

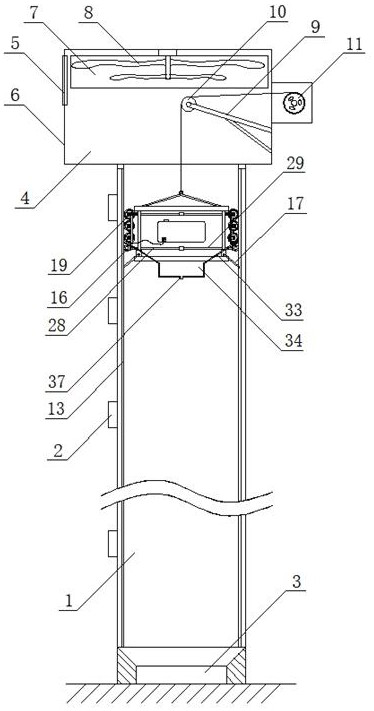

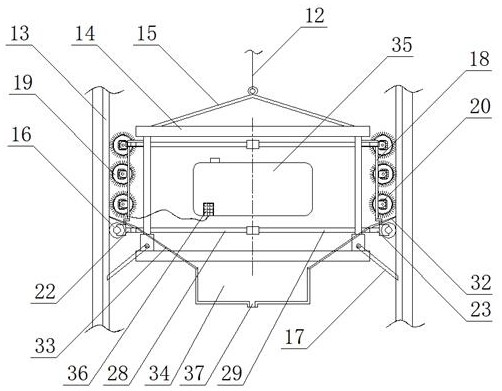

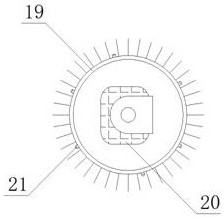

[0023] see Figure 1 to Figure 4 , a kind of environment-friendly high-rise building public flue structure of the present invention and flue cleaning system thereof, comprise flue shaft 1, offer on the side wall of flue shaft 1 corresponding floor flue mouth 2 with the kitchen of each floor , it is characterized in that: the bottom of the flue shaft 1 is provided with an oil storage tank 3, the top of the flue shaft 1 is provided with a roof smoke exhaust chamber 4, and the top of the roof smoke exhaust chamber 4 is provided with an oil fume filter chamber 7, A fume filter 8 is installed in the oil fume filter cavity 7, side exhaust outlets 5 are respectively provided on the sides around the upper part of the smoke exhaust chamber 4 on the roof, and an inspection port 6 is provided on the lower side of the smoke exhaust chamber 4 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com