Boiler fuel gas dedusting purifying device

A technology for purifying device and boiler flue gas, applied in gas treatment, transportation and packaging, chemical instruments and methods, etc., can solve problems such as harm to people's physical and mental health, sulfide pollution, poor dust treatment effect, etc., and achieve good dust removal and filtering effect. , to achieve the effect of environmental protection emission and speed up the flow of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments:

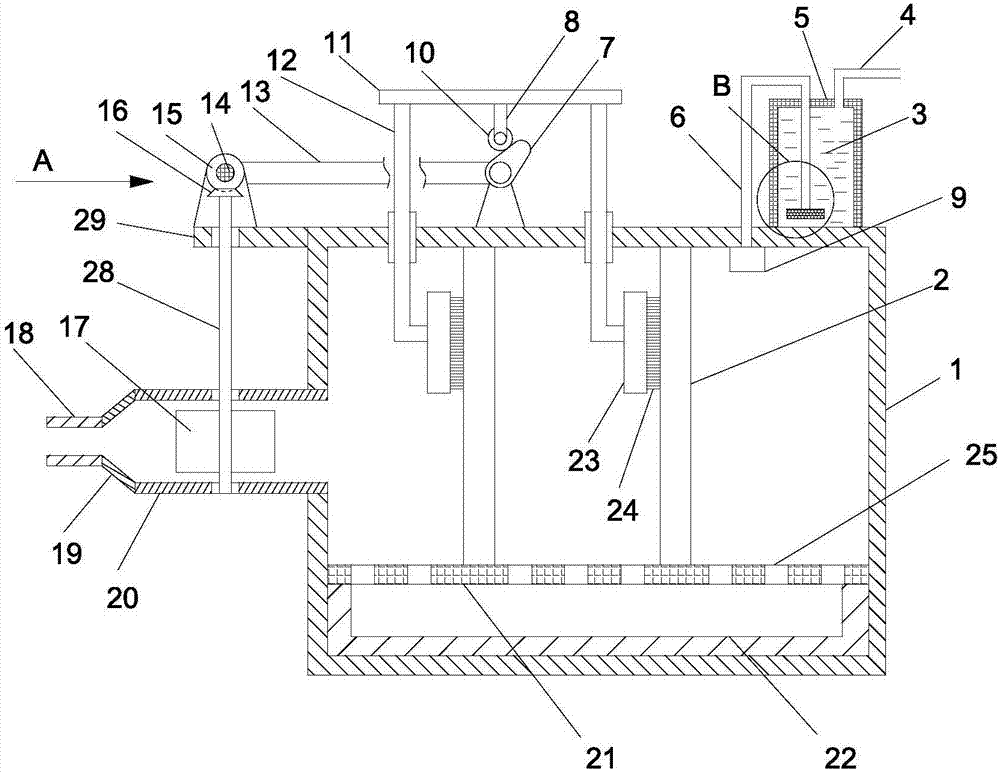

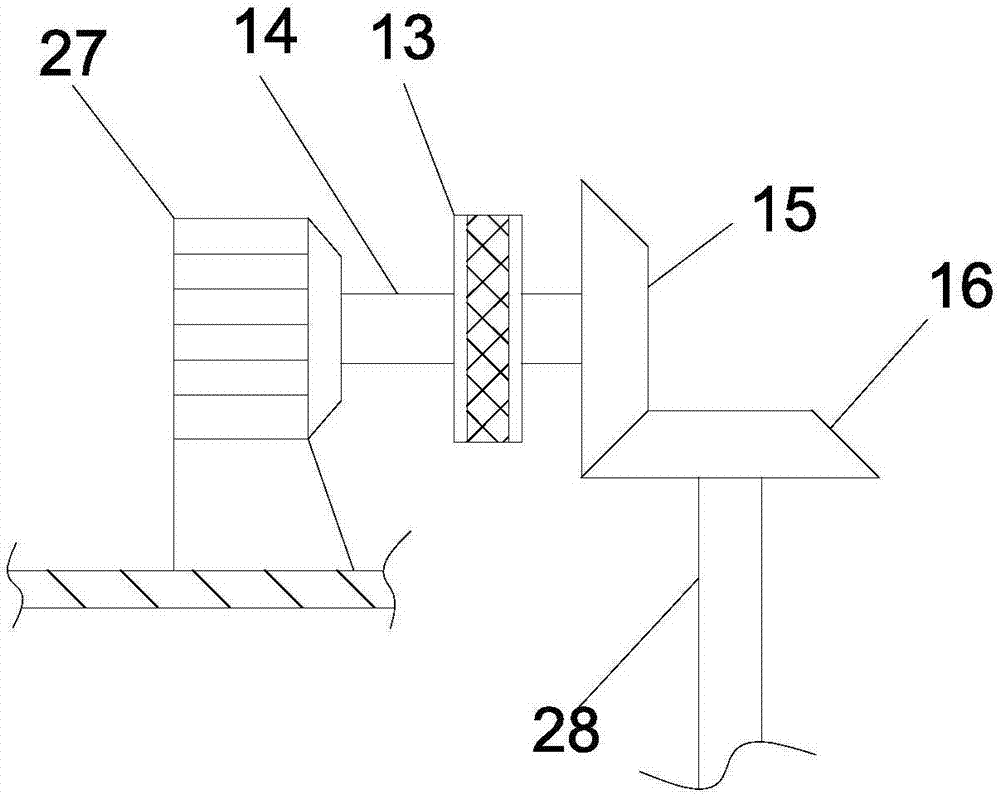

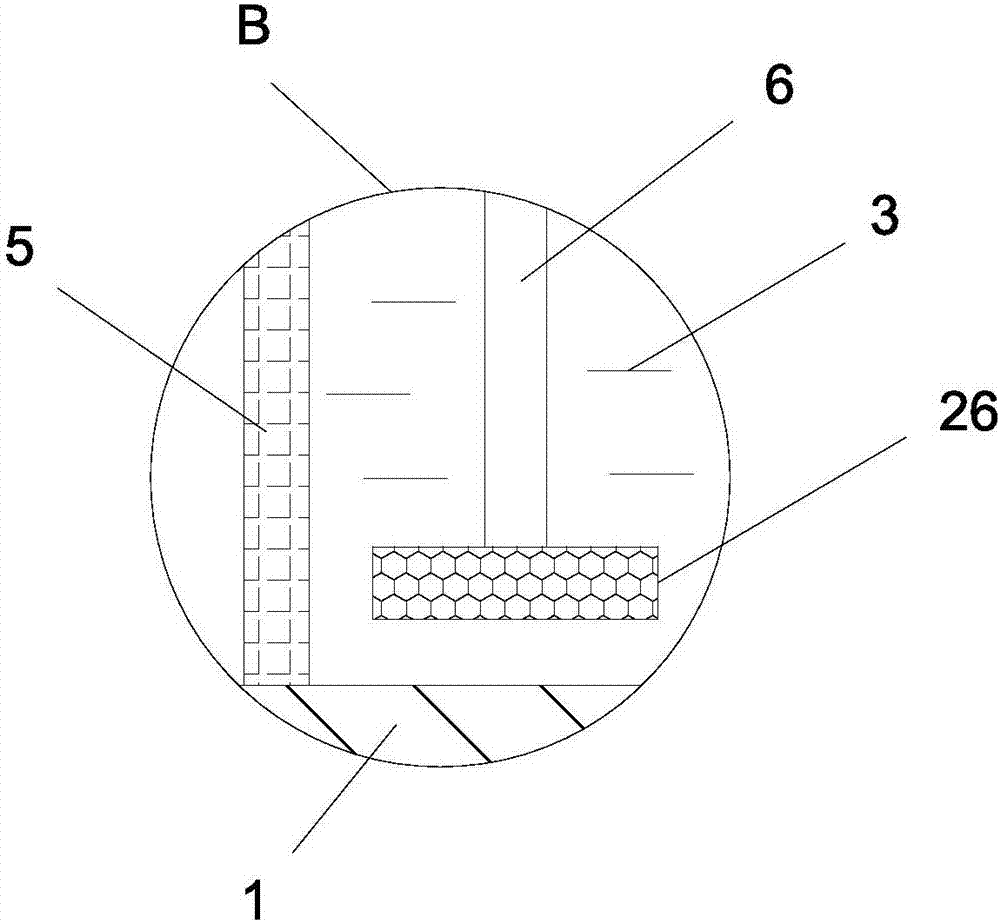

[0020] see Figure 1-4 , a boiler flue gas dust removal and purification device, including a dust removal chamber 1, a speed-increasing tube 20 extending horizontally to the left on the left side wall of the dust-removing chamber 1, and a concentric reducer 19 installed at the left end of the speed-up tube 20, The diameter of the left end of the concentric reducer 19 is smaller than the diameter of the right end, and the left end of the concentric reducer 19 is equipped with an air inlet pipe 18; the left side of the dust removal chamber 1 is fixed with an extension plate 29, and the extension plate 29 is horizontally extended to the left. The drive motor 27 is fixedly installed on the extension plate 29, the drive shaft 14 is fixedly installed on the drive motor 27, the drive shaft 14 is provided with a belt transmission mechanism 13, and the drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com