Coal chemical wastewater pretreatment method and pretreatment system

A coal chemical wastewater and pretreatment technology, which is applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of restricting industrialization promotion, a large amount of iron sludge, and high cost of chemicals, so as to improve the ability of flocculation and sedimentation , fast response and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to the treatment of coal chemical wastewater.

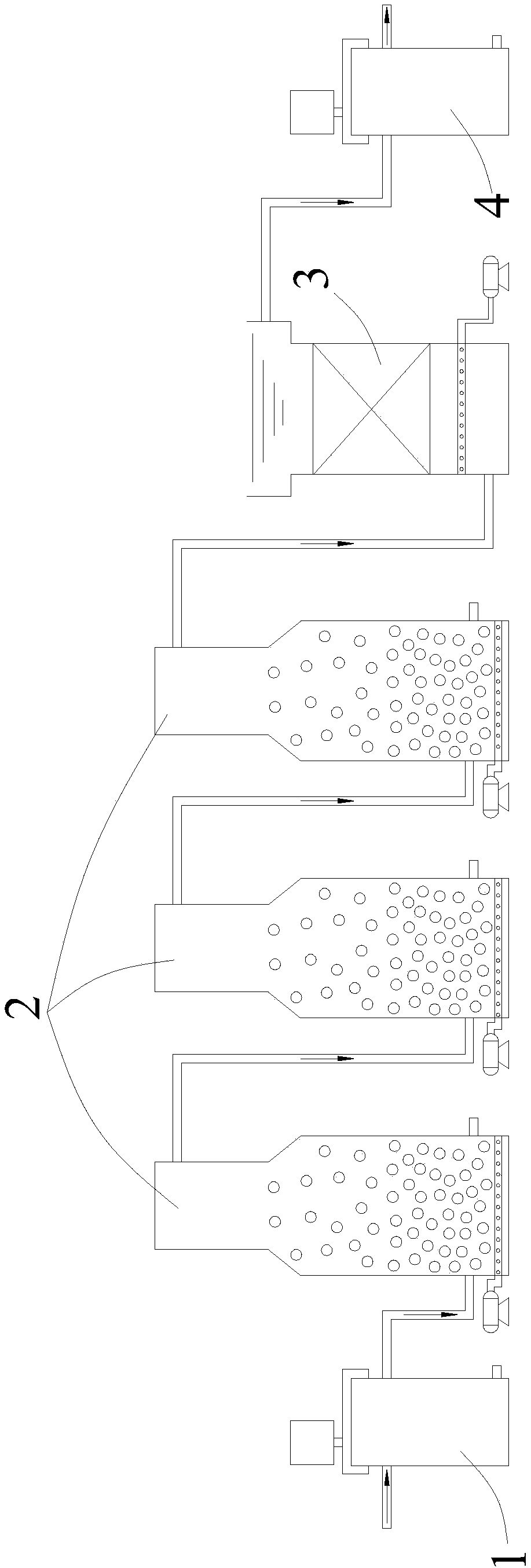

[0040] The coal chemical industry wastewater is treated in the following pretreatment system:

[0041] Along the waste water flow direction, the treatment system includes a first flocculation sedimentation tank connected in sequence, a number of catalytic oxidation towers connected in series, an internal electrolysis reaction tower and a second flocculation sedimentation tank. The top of each is equipped with a dosing port, and the dosing port is connected to the dosing box through a pipeline, and is used to add flocculant to the first flocculation-settling tank and the second flocculation-settling tank; between the first flocculation-settling tank and the second The bottom of the flocculation sedimentation tank is equipped with a sewage outlet for discharging the sediment at the bottom of the tank. A microporous aerator is provided at the inner bottom of the catalytic oxidation tower, and the micr...

Embodiment 2

[0051] This embodiment relates to the treatment of coal chemical wastewater.

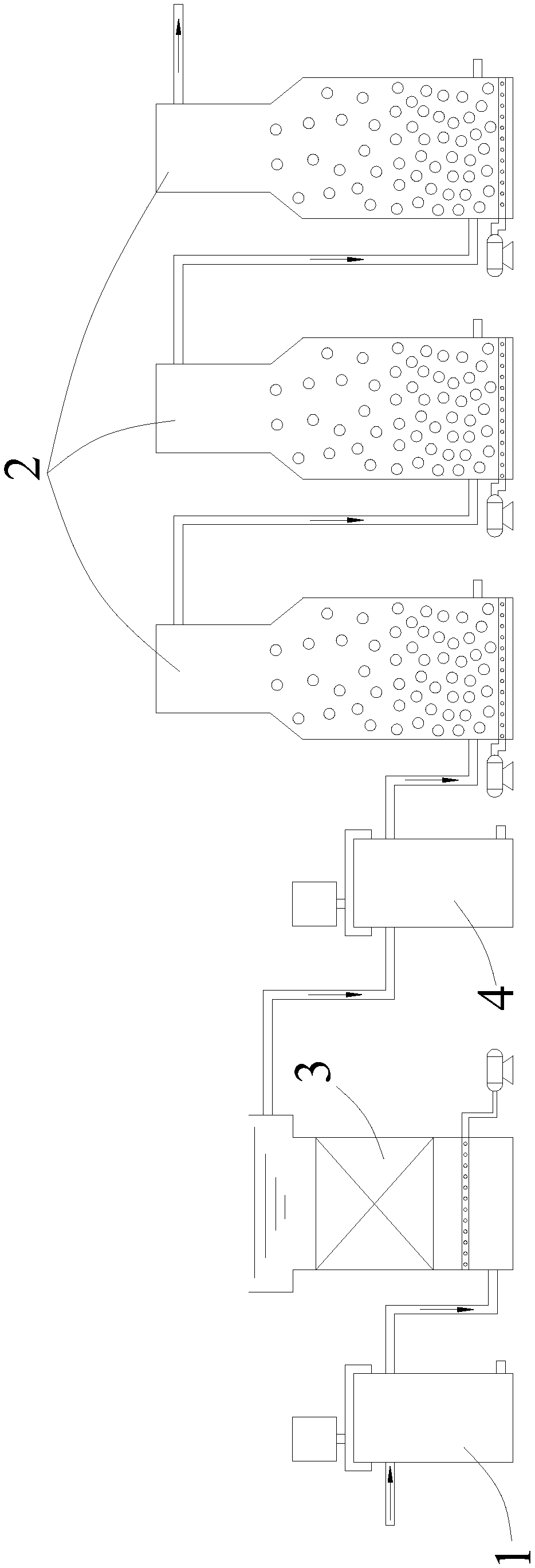

[0052] The coal chemical industry wastewater is treated in the following pretreatment system:

[0053] Along the waste water flow direction, the treatment system includes a first flocculation sedimentation tank, an internal electrolytic reaction tower, a second flocculation sedimentation tank, and several catalytic oxidation towers connected in series. The top of each is equipped with a dosing port, and the dosing port is connected to the dosing box through a pipeline, and is used to add flocculant to the first flocculation-settling tank and the second flocculation-settling tank; between the first flocculation-settling tank and the second The bottom of the flocculation sedimentation tank is equipped with a sewage outlet for discharging the sediment at the bottom of the tank. A microporous aerator is provided at the inner bottom of the catalytic oxidation tower, and the microporous aerator is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com