Crushing and sorting integrated automatic processor for waste plastics

A technology for waste plastics and processing machines, which is used in plastic recycling, solid separation, mechanical material recycling, etc., to save sorting labor, increase added value, and improve accuracy and depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

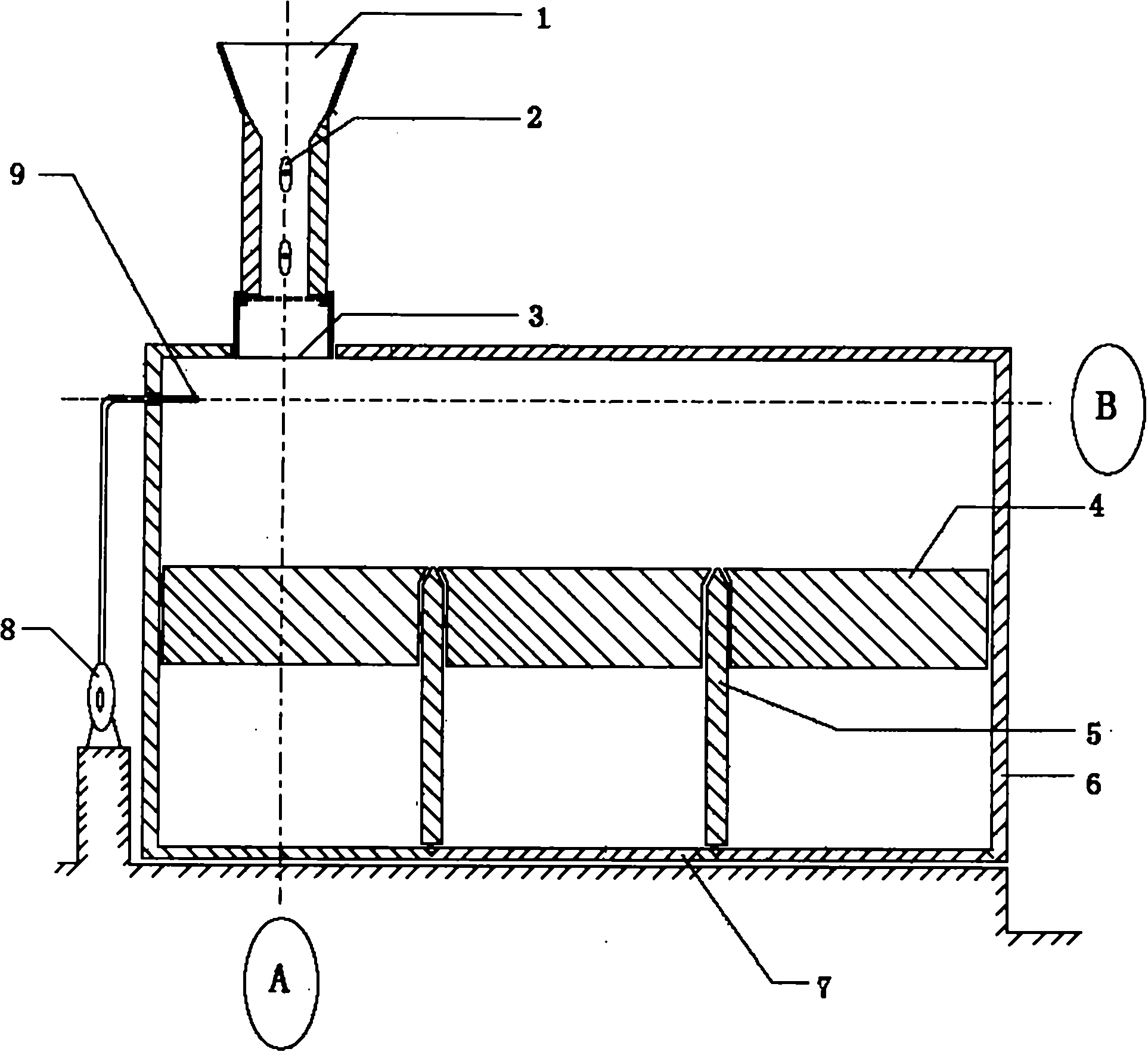

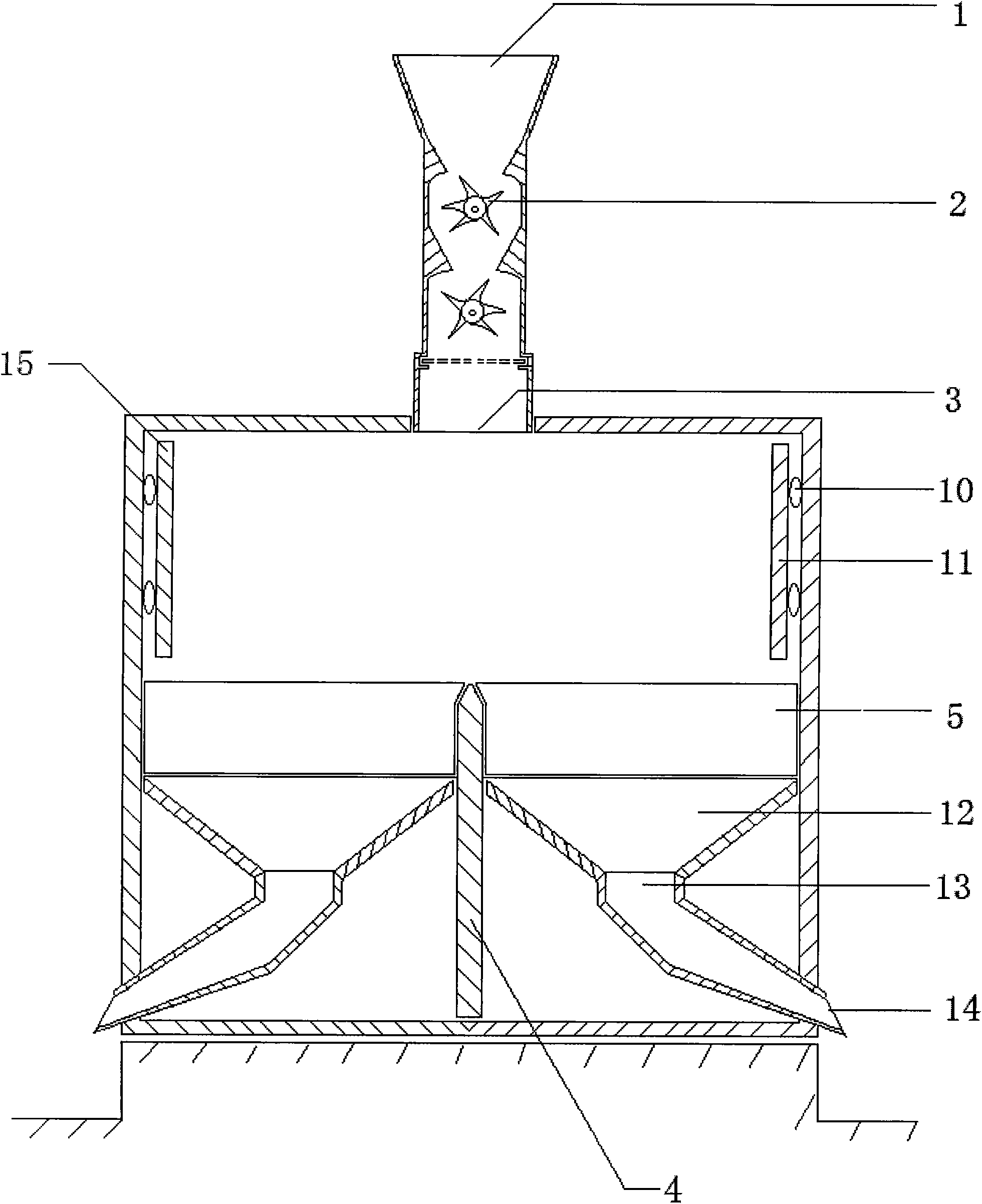

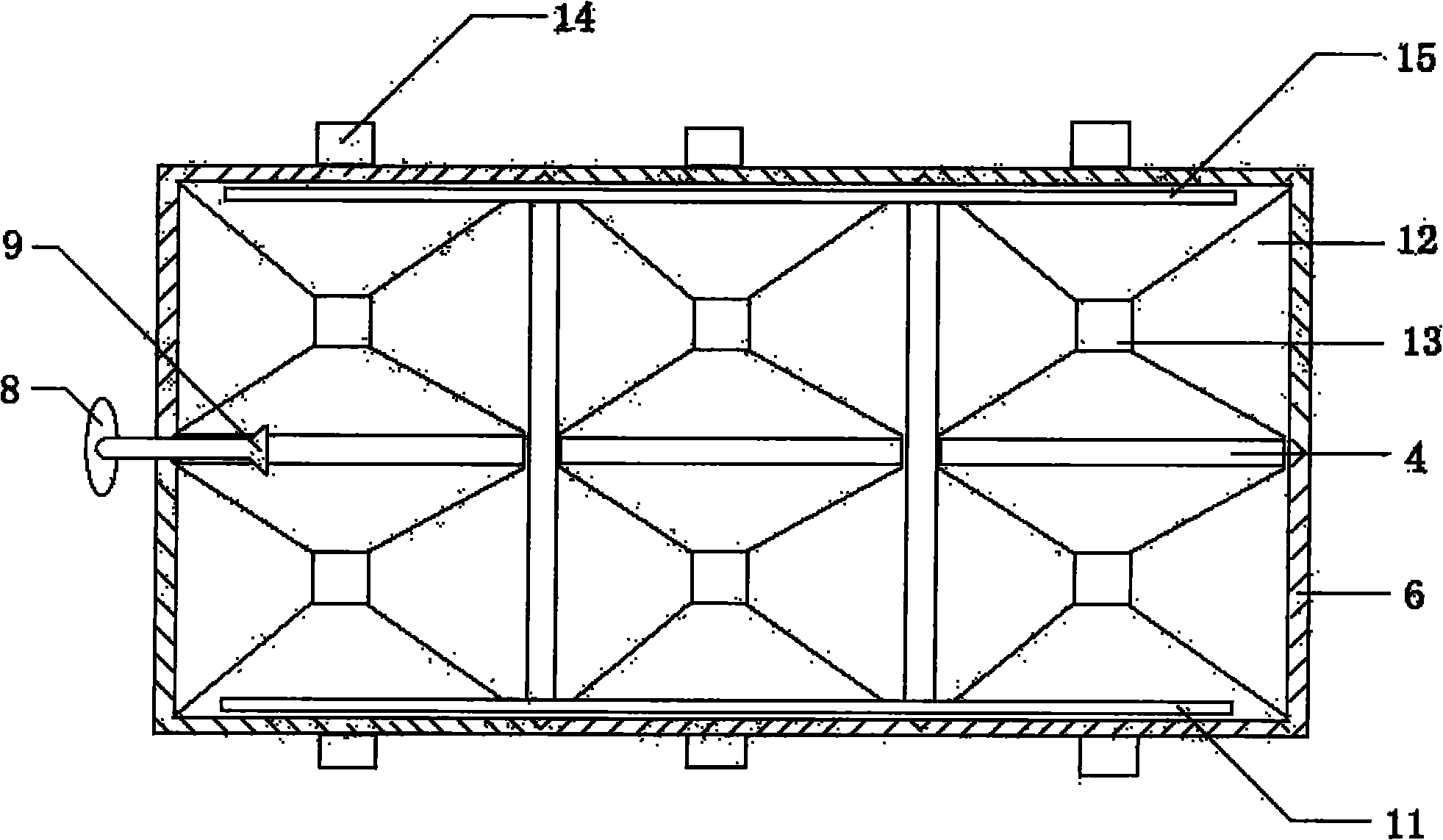

[0024] According to the structure described in the accompanying drawings, a box body of 2700mm×1800mm×2000mm (length×width×height) is prepared, and a longitudinal partition 4 is arranged between 800mm and 1000mm away from the bottom plate, and a longitudinal partition 4 is arranged on the longitudinal third equal position There are transverse partitions 5, longitudinal partitions 4 and transverse partitions 5 to form a rectangular vertical frame, and the lower edge of the rectangular vertical frame is equipped with sorting buckets. There are 6 sorting buckets in total. The outlet 14 of the waste plastic crushing and sorting integrated processing machine after completion is located on the inner wall of the front and rear walls of the box. There are 100mm×2000mm steel plate cathode and anode electrodes, which are respectively connected to the positive and negative currents in the box. An electric field is formed; the air screen device is located on the central axis on the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com