Intelligent joint robot stacking system and control system thereof

A palletizing system and control system technology, applied in the field of intelligent joint robot palletizing system and its control system, can solve problems such as difficult planning and layout, and achieve the effects of saving manpower, stable and reliable system operation, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

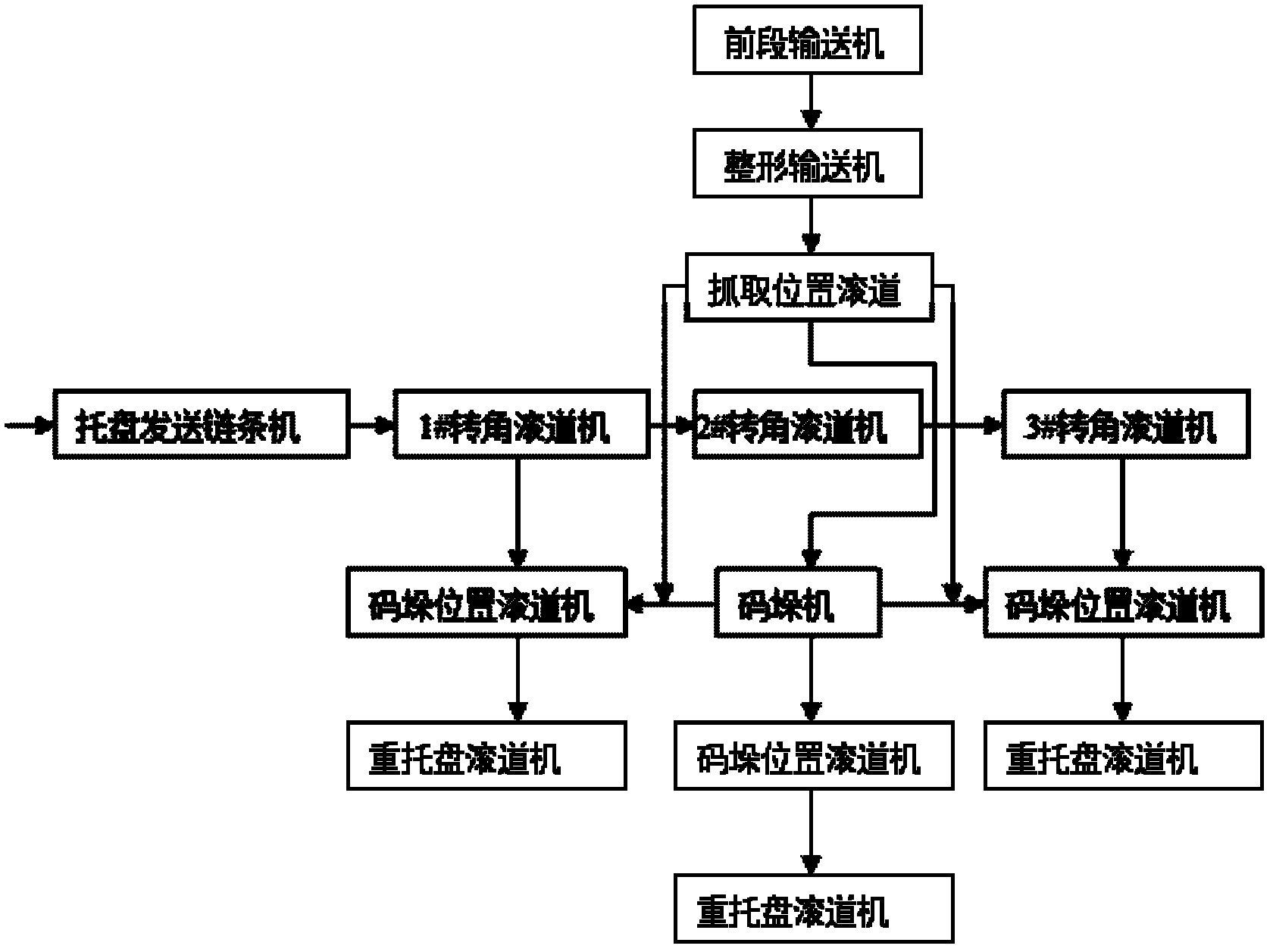

[0028] like figure 1 The structure of the intelligent robot palletizing system for distinguishing and palletizing a variety of products of the same type (such as bagged products or boxed products) but different types of products conveyed by one conveyor line according to an embodiment of the present invention is shown. Schematic diagram of location distribution. In this embodiment, the intelligent robot palletizing system and its control system are illustrated by taking three different types of products simultaneously for palletizing operation as an example. In this embodiment, the location distribution of the intelligent robot palletizing system includes the following parts:

[0029] The first part includes the front conveyor, the shaping conveyor and the grab position raceway (the palletizer will grab the products to be palletized at the grab position). The function of this part is to receive the packaged products transmitted by the previous process, and arrange and straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com