Material disc of automatic material feeding device

A technology of automatic feeding and trays, applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve problems such as difficult sorting, manual sorting, loose exhaust pipes, etc., to reduce production costs, improve work efficiency, improve The effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in further detail below in conjunction with the accompanying drawings.

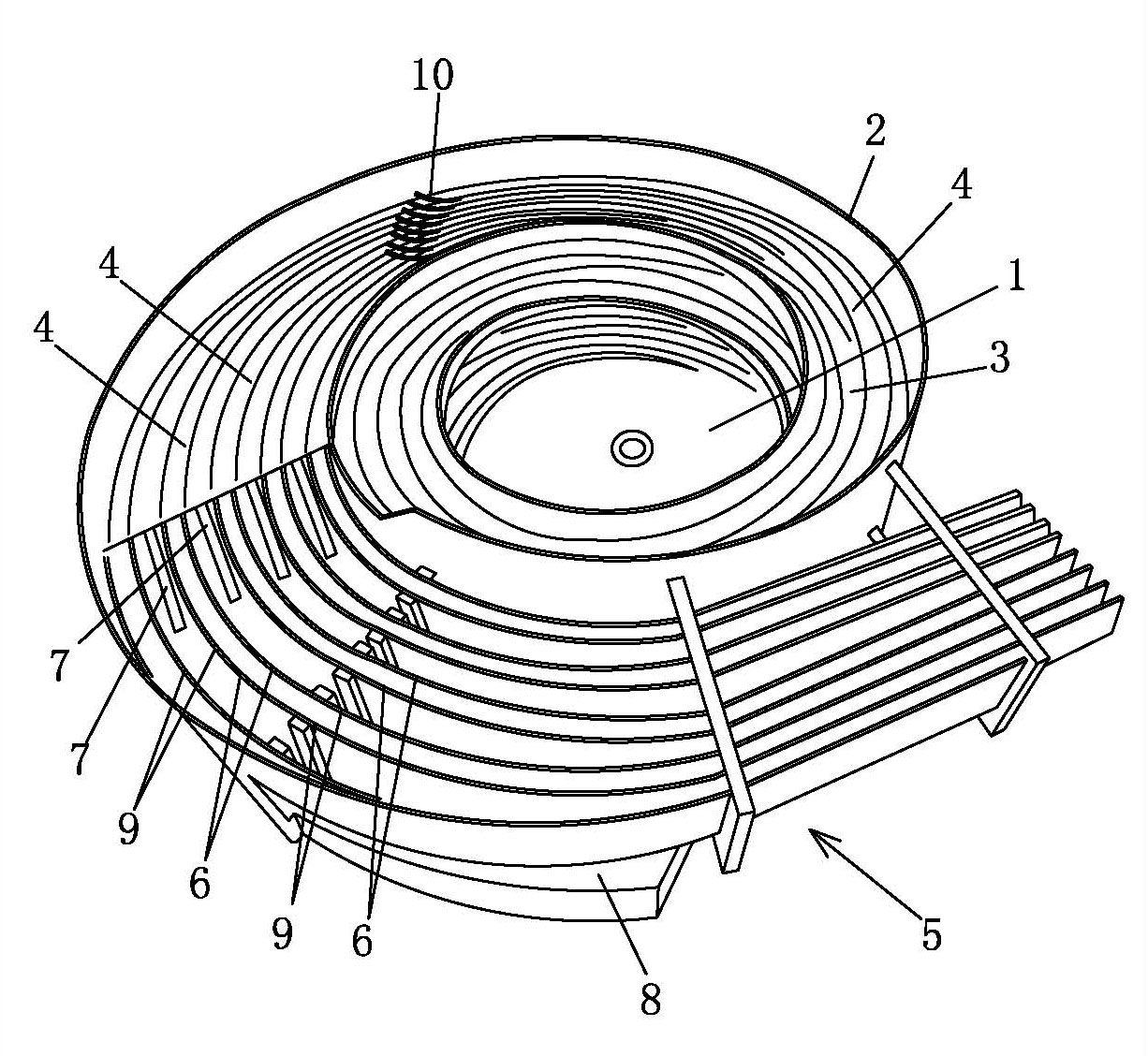

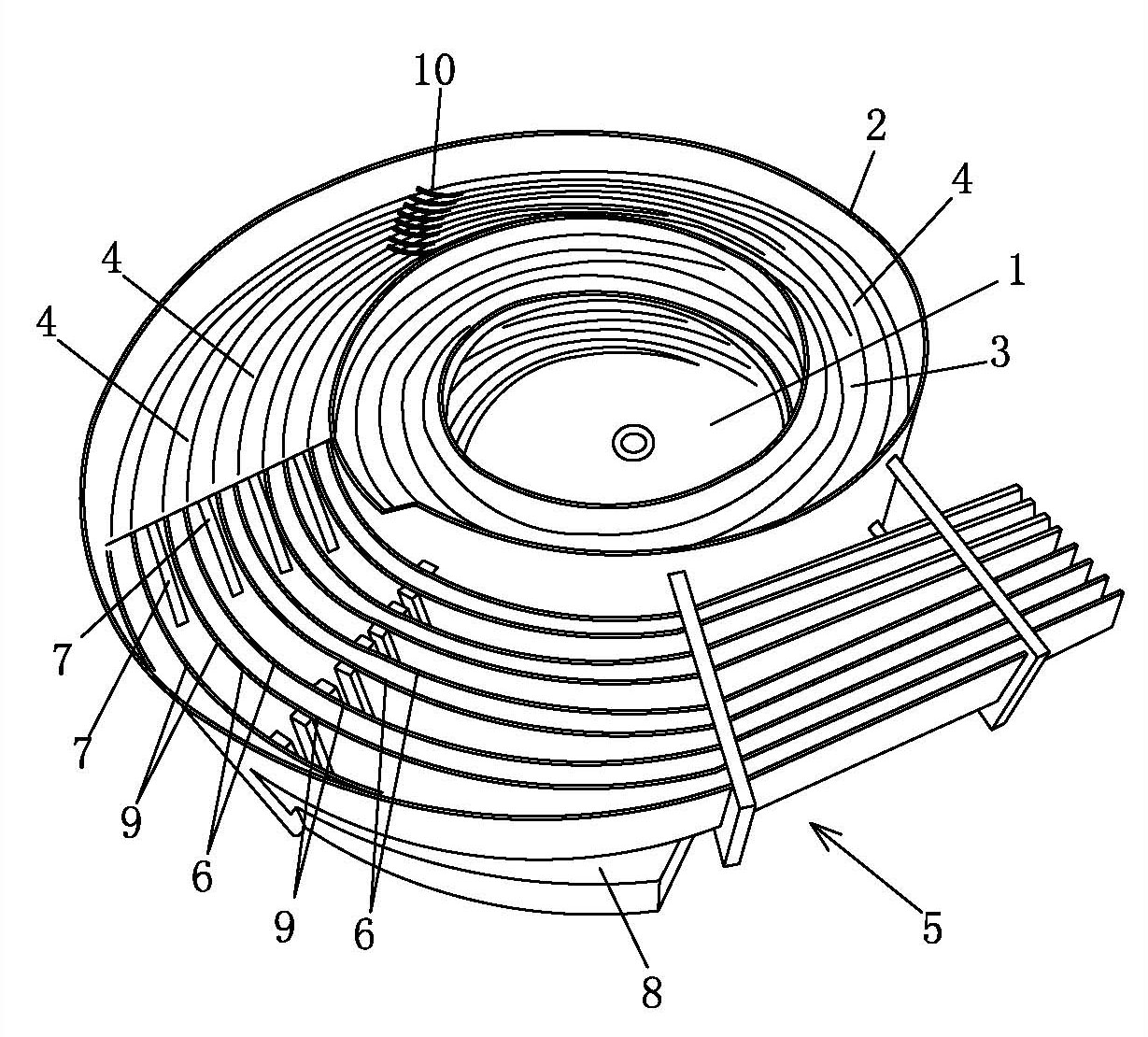

[0018] Such as figure 1 with figure 2 As shown, a feeding tray of an automatic feeding device includes a tray surface 1 and a side wall 2 surrounding the tray surface 1. A spirally rising feeding track 3 is arranged on the inner side of the side wall 2, and the feeding end of the feeding track 3 is located at the bottom of the tray surface 1. At the lower part, the surface of the feeding track 3 is provided with a plurality of partitions 4 side by side. The discharge end of the feeding track 3 is connected to the monolithic rail 5 , and the monolithic rail 5 includes a hanging path 6 and a blanking path 9 . The feeding port of hanging road 6 is connected with the discharging port of every other road in one-to-one correspondence, and blanking road 9 is arranged between adjacent hanging roads 6 . The periphery of the monolith track 5 is provided with a collection gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com