Recycling method for waste CO sulfur-tolerant shift catalysts

A waste catalyst, sulfur-resistant shift technology, used in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of narrow active temperature range, very sensitive poisons, insufficient purity, etc., and achieve no secondary pollution. , the effect of saving molybdenum resources and improving sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

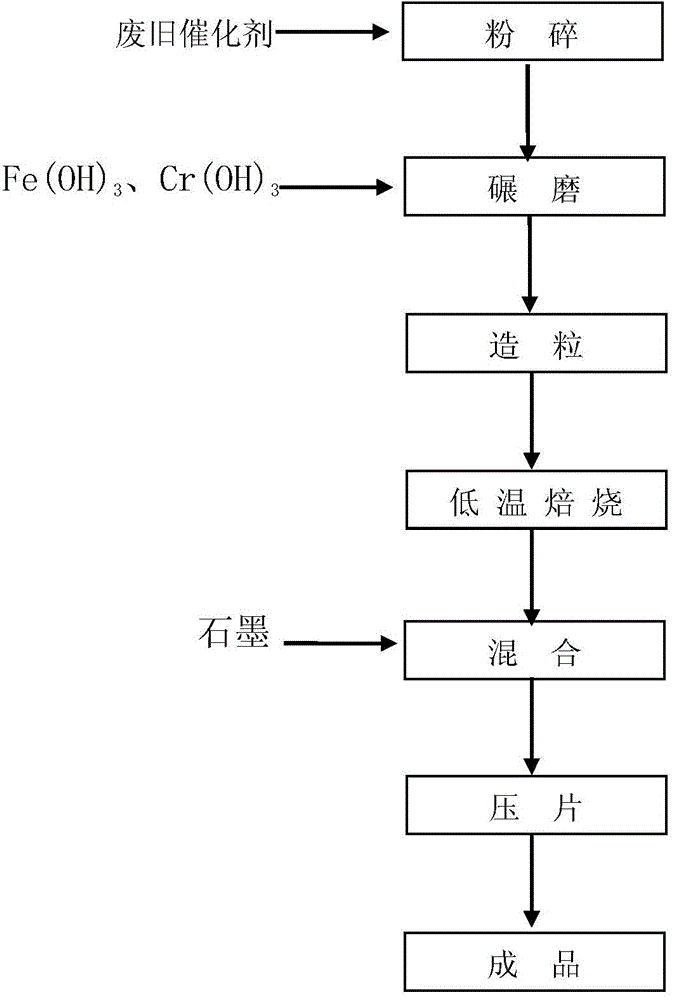

Image

Examples

Embodiment 1

[0019] A kind of spent CO sulfur-resistant shift catalyst, through X-ray fluorescence analysis, its composition is mass fraction (%): Co (calculated as CoO): 3.8%, Mo (calculated as MoO 3 Total): 11.5%, K 2 O: 1.5%, S (as SO 2 Total): 14.1%, Al 2 o 3 : 69.1%. This spent catalyst is crushed to 100 orders, gets the waste catalyst after 18kg pulverizes, and 200kgFe(OH) 3 (with Fe 2 o 3 Mass fraction ≥ 70%), 18kgCr(OH) 3 (in Cr 2 o 3 mass fraction ≥ 61%) together for 1 to 2 hours, passed through an 8-mesh screen to make particles, roasted at a low temperature of 250°C to 300°C for 6 to 8 hours, and then mixed with graphite and pressed into tablets to form a CO high temperature shift catalyst . According to the national chemical industry standard HG / T 3546-2011, the activity (calculated by the conversion rate of carbon monoxide): 61%; the average particle radial crush resistance: 365N / cm; the particle fraction below 160N / cm: 5% ; Wear rate: 3.2%; Loss on ignition mass fr...

Embodiment 2

[0021] A kind of spent CO sulfur-resistant shift catalyst, through X-ray fluorescence analysis, its composition is mass fraction (%): Co (calculated as CoO): 2.6%, Mo (calculated as MoO 3 Total): 9.8%, K 2 O: 2.0%, S (as SO 2 Total): 11.7%, Al 2 o 3 : 73.9%. This waste catalyst is pulverized to 120 order, gets the waste catalyst after 20kg pulverizes, and 200kgFe(OH) 3 (with Fe 2 o 3 Mass fraction ≥ 70%), 18kgCr(OH) 3 (in Cr 2 o 3 mass fraction ≥ 61%) together for 1 to 2 hours, passed through an 8-mesh screen to make particles, roasted at a low temperature of 250°C to 300°C for 6 to 8 hours, and then mixed with graphite and pressed into tablets to form a CO high temperature shift catalyst . According to the national chemical industry standard HG / T 3546-2011, the activity (calculated by the conversion rate of carbon monoxide): 62%; the average particle radial crush resistance: 352N / cm; the particle fraction below 160N / cm: 0% ; Wear rate: 3.0%; Loss on ignition mass f...

Embodiment 3

[0023] A kind of spent CO sulfur-resistant shift catalyst, through X-ray fluorescence analysis, its composition is mass fraction (%): Co (calculated as CoO): 1.5%, Mo (calculated as MoO 3 Total): 8.6%, K 2 O: 4.8%, S (as SO 2 Total): 9.2%, Al 2 o 3 : 75.9%. This spent catalyst is crushed to 120 orders, gets spent catalyst after 22kg crushes, and 200kgFe(OH) 3 (with Fe 2 o 3 Mass fraction ≥ 70%), 18kgCr(OH) 3 (in Cr 2 o 3 mass fraction ≥ 61%), milled together for 1-2 hours, passed through an 8-mesh screen to make particles, roasted at a low temperature of 250°C-300°C for 6-8h, and then mixed with graphite and pressed into tablets to form a CO high-temperature shift catalyst . According to the national chemical industry standard HG / T 3546-2011, the activity (calculated by the conversion rate of carbon monoxide): 60%; the average particle radial crush resistance: 382N / cm; the particle fraction below 160N / cm: 0% ; Wear rate: 2.8%; Loss on ignition mass fraction: 6.7%; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com