Air conveyor

A technology of pneumatic conveyors and cylinders, which is applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of simple way to supplement air source pressure, high transportation cost, and inability to replenish air, so as to avoid secondary pollution. , The effect of improving the conveying capacity and reducing the conveying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

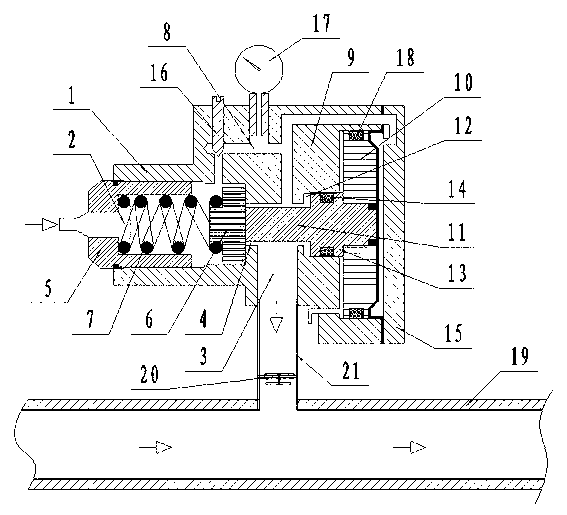

[0015] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0016] Such as figure 1 A pneumatic conveyor shown includes a body 1, the body 1 contains two chambers, an air inlet chamber 2 and an air outlet chamber 3, and an inner hole 4 communicates between the two chambers; one end of the air inlet chamber 2 is fixed with a A connecting pipe 5 connected to the main body 1; a valve plate 6 is provided at the inner hole, and a spring 7 for pressing the valve plate is arranged between the valve plate and the connecting pipe; a communication outlet is opened on the side wall of the air intake chamber 2 The drain hole 8 of the chamber 3; the body 1 also includes a cylinder, and the cylinder includes a cylinder body 9 integrated with the body, and the other end of the cylinder body 9 is equipped with a sealed end cover 15; a piston 10 is slidably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com