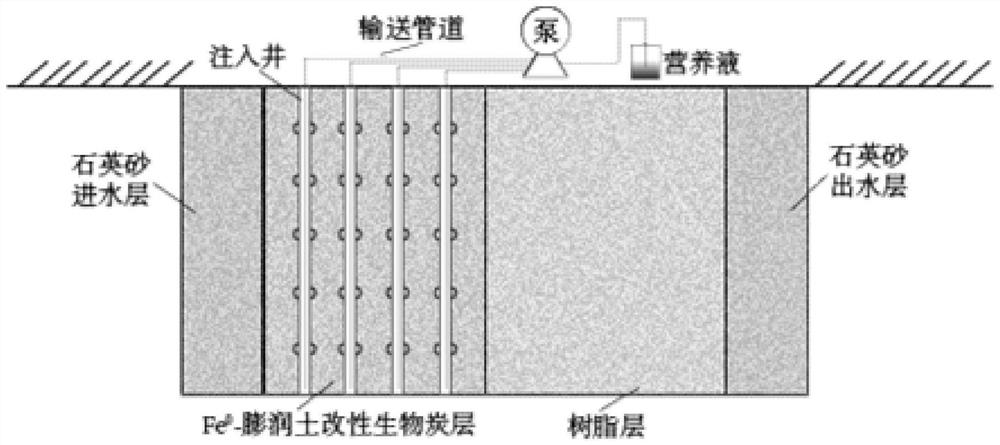

Composite permeable reactive barrier system based on Fe < 0 >-bentonite modified biochar filler and application of composite permeable reactive barrier system

A osmotic reaction wall and biochar technology, applied in biological water/sewage treatment, water pollutants, water/sewage treatment, etc., can solve secondary pollution, endanger human health and other problems, prevent clogging and ensure service life , The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Fe 0 -Bentonite modified biochar layer

[0039] (1) Preparation of Fe 0 -Bentonite modified biochar:

[0040] (a) fully stir and mix bentonite and coconut shell biochar according to the mass ratio of 1:20, the stirring speed is 500r / min, the stirring time is 30min, and then stand still for 48h;

[0041] (b) mix the material in step (a) in N 2 Carry out pyrolysis under the atmosphere, the pyrolysis temperature is 500°C, and the pyrolysis time is 40min to obtain bentonite modified biochar;

[0042] (c) fully stir and mix the bentonite modified biochar and zero-valent iron in step (b), wherein the quality of zero-valent iron is 10% of the biochar quality, the stirring speed is 400r / min, and the stirring time is 40min , get Fe 0 -Bentonite modified biochar.

[0043] Wherein, the particle size of the biochar is 10 mesh, the particle size of the bentonite is 80 mesh, and the particle size of the zero-valent iron is 100 mesh.

[0044] (2) Preparation of Fe loaded wit...

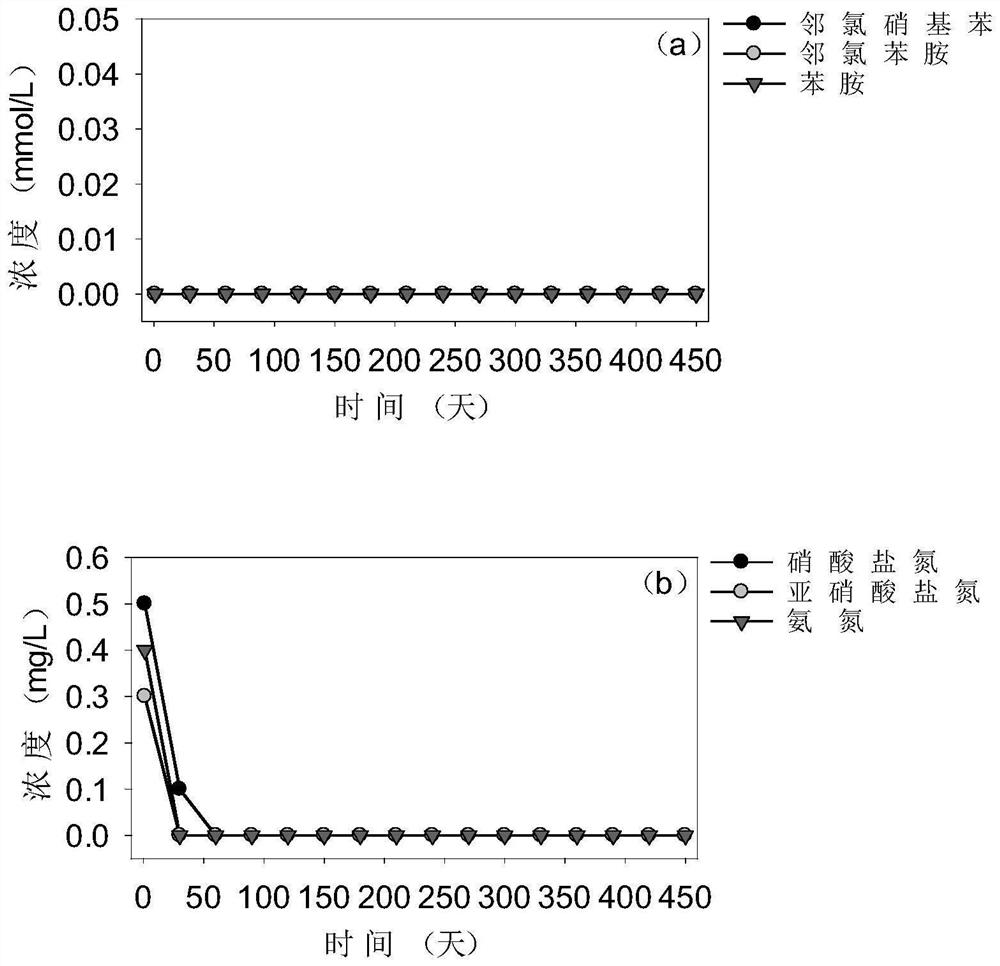

Embodiment 2

[0055] Embodiment 2: a kind of based on Fe 0 -The composite permeable reaction wall system of bentonite modified biochar filler and its preparation method are basically the same as in Example 1, except that:

[0056] 1. Fe 0 -Bentonite modified biochar layer

[0057] (1) Preparation of Fe 0 -Bentonite modified biochar:

[0058] (a) fully stir and mix bentonite and coconut shell biochar according to the mass ratio of 1:15, the stirring speed is 550r / min, the stirring time is 40min, and then stand still for 48h;

[0059] (b) mix the material in step (a) in N 2 Carry out pyrolysis under the atmosphere, the pyrolysis temperature is 550°C, and the pyrolysis time is 50min to obtain bentonite modified biochar;

[0060] (c) Fully stir and mix the bentonite modified biochar and zero-valent iron in step (b), wherein the quality of zero-valent iron is 20% of the biochar quality, the stirring speed is 600r / min, and the stirring time is 50min , get Fe 0 -Bentonite modified biochar. ...

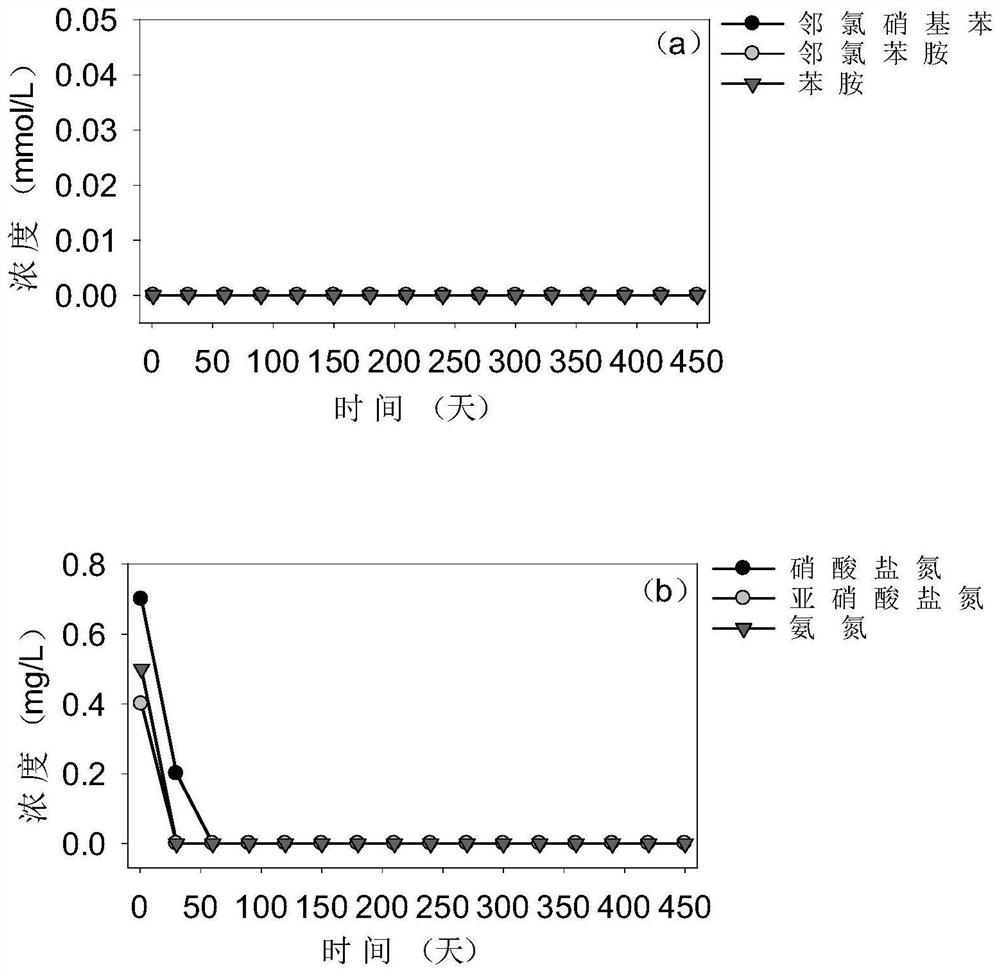

Embodiment 3

[0072] Embodiment 3: a kind of based on Fe 0 -The composite permeable reaction wall system of bentonite modified biochar filler and its preparation method are basically the same as in Example 1, except that:

[0073] 1. Fe 0 -Bentonite modified biochar layer

[0074] (1) Preparation of Fe 0 -Bentonite modified biochar:

[0075] (a) fully stir and mix bentonite and coconut shell biochar according to the mass ratio of 1:10, the stirring speed is 600r / min, the stirring time is 60min, and then stand still for 48h;

[0076] (b) mix the material in step (a) in N 2 Carry out pyrolysis under the atmosphere, the pyrolysis temperature is 600°C, and the pyrolysis time is 60 minutes to obtain bentonite modified biochar;

[0077] (c) fully stir and mix the bentonite modified biochar and zero-valent iron in step (b), wherein the quality of zero-valent iron is 30% of the biochar quality, the stirring speed is 800r / min, and the stirring time is 60min , get Fe 0 -Bentonite modified biocha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com