Medical waste recovery treatment device

A technology for medical waste, recycling and treatment, applied in grain treatment, solid waste removal, waste disinfection or sterilization methods, etc. Harmful treatment, good effect, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

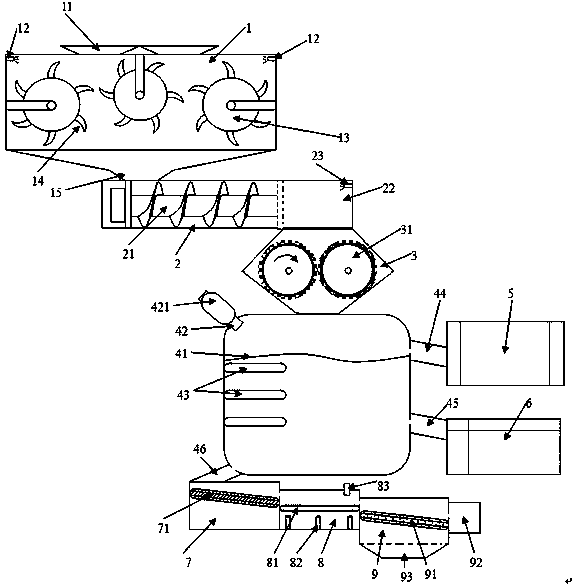

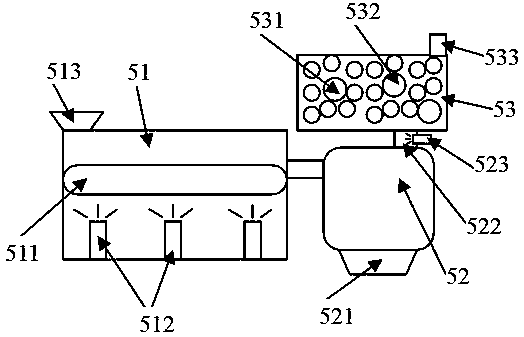

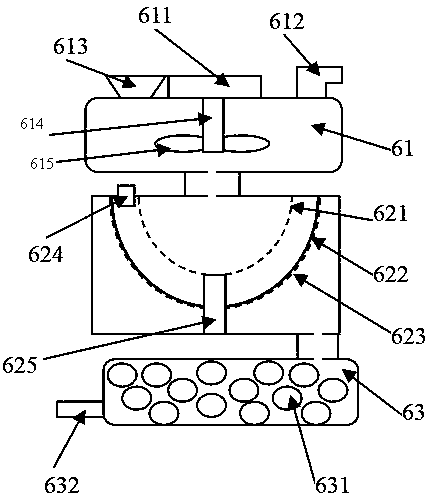

[0039] A medical waste recycling and processing device includes a coarse broken chamber, a fine broken chamber, a grinding chamber, a sedimentation chamber, a float treatment device, a liquid treatment device and a sediment treatment device.

[0040] The coarse crushing cavity includes a coarse crushing cavity casing, a waste inlet, a coarse crushing cavity disinfection water nozzle, crushing parts and a coarse crushing cavity outlet. The side wall of the broken cavity shell is provided with a plurality of coarse broken cavity disinfection water nozzles, and the crushing parts are 3, which are respectively fixed to the side wall and the top of the rough broken cavity shell through brackets. And the arc-shaped crushing knife arranged on the side wall of the crushing shaft is recessed downward at the bottom of the rough crushing cavity shell to form the coarse crushing cavity outlet.

[0041] The outlet of the coarse cavity is provided with a valve, which is used to control the ...

Embodiment 2

[0061] A medical waste recycling and processing device includes a coarse broken chamber, a fine broken chamber, a grinding chamber, a sedimentation chamber, a float treatment device, a liquid treatment device and a sediment treatment device.

[0062] The coarse crushing cavity includes a coarse crushing cavity casing, a waste inlet, a coarse crushing cavity disinfection water nozzle, crushing parts and a coarse crushing cavity outlet. The side wall of the broken cavity shell is provided with a plurality of coarse broken cavity disinfection water nozzles, and the number of crushing parts is 6, which are fixed to the side wall and top of the rough broken cavity shell through brackets respectively. And the arc-shaped crushing knife arranged on the side wall of the crushing shaft is recessed downward at the bottom of the rough crushing cavity shell to form the coarse crushing cavity outlet.

[0063]The fine crushing cavity is arranged at the lower part of the coarse crushing cavit...

Embodiment 3

[0083] A medical waste recycling and processing device includes a coarse broken chamber, a fine broken chamber, a grinding chamber, a sedimentation chamber, a float treatment device, a liquid treatment device and a sediment treatment device.

[0084] The coarse crushing cavity includes a coarse crushing cavity casing, a waste inlet, a coarse crushing cavity disinfection water nozzle, crushing parts and a coarse crushing cavity outlet. The side wall of the broken cavity shell is provided with a plurality of coarse broken cavity disinfection water nozzles. The crushing parts are five, which are respectively fixed to the side wall and the top of the rough broken cavity shell through brackets. The crushing parts include a horizontally arranged crushing shaft And the arc-shaped crushing knife arranged on the side wall of the crushing shaft is recessed downward at the bottom of the rough crushing cavity shell to form the coarse crushing cavity outlet.

[0085] The fine crushing cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com