Corrosion test method for simulating truck body steel in coal leachate medium

A corrosion test, leachate technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem of no accelerated test method of coal leachate, and achieve the effect of good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

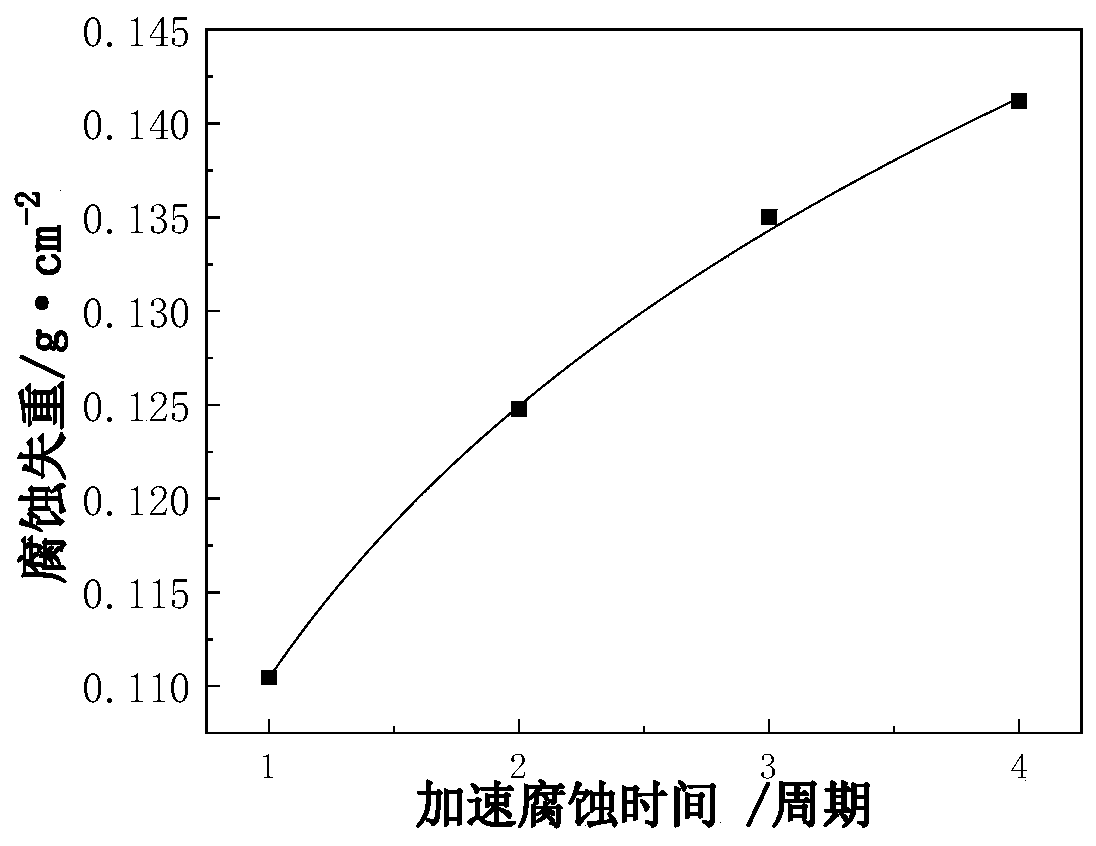

[0019] The invention provides a method for simulating the corrosion test of the steel used for the truck body in the coal leaching liquid medium, which can satisfy three basic conditions of simulation, acceleration and reproducibility.

[0020] The following will be described in conjunction with specific embodiments.

[0021] The method steps are:

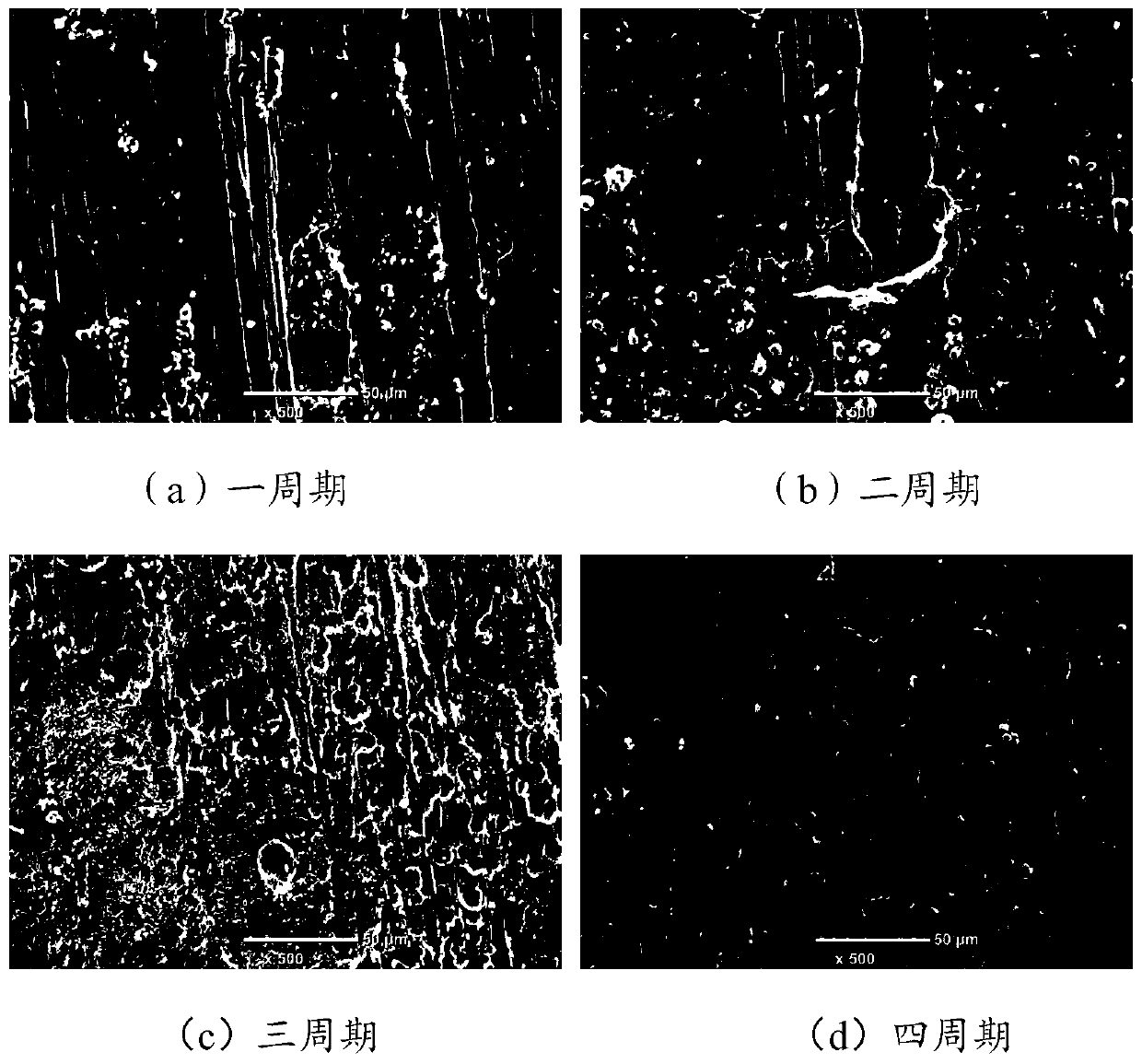

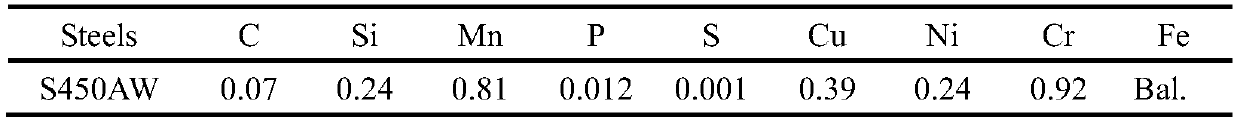

[0022] (1) The weathering steel S450AW is used as the test material. The chemical composition is shown in Table 1. The wire cutting size of the sample used in the accelerated corrosion test is 150mm (length) × 75mm (width) × 4mm (thickness). The cut samples were polished with 150#, 240#, 400#, 800# sandpaper in turn, degreased with acetone, rinsed with deionized water, dehydrated with ethanol solution, dried with a hair dryer, and then stored in a desiccator. Before the test, the size of the sample was measured with a vernier caliper, and the initial weight was weighed with a balance with an accuracy of 0.1 mg.

[0023] Table 1 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com