Test method for simulating corrosion process of stainless steel in industrial marine atmosphere

A marine atmosphere and corrosion process technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem of less stainless steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

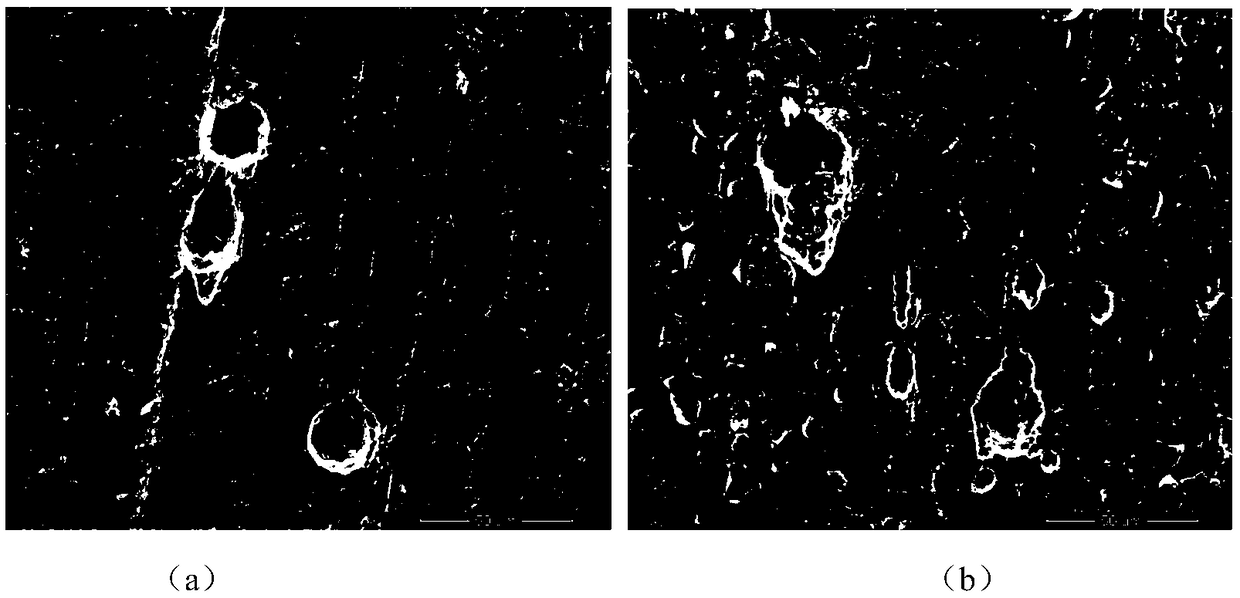

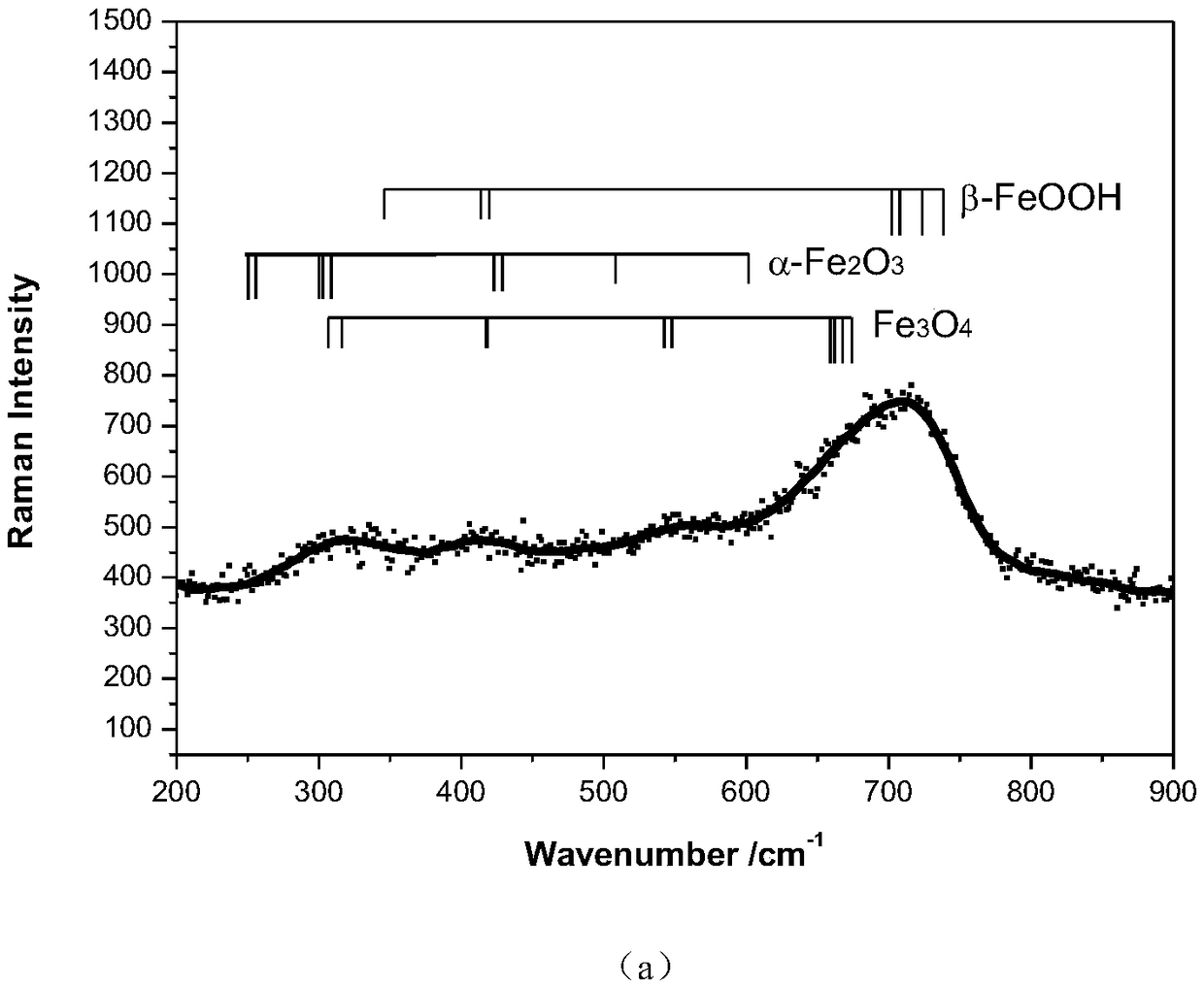

[0044] The experimental material is 316L stainless steel, and the ultraviolet irradiation test is carried out on the sample first, and the irradiation intensity is 60W / m 2 , the temperature is 50°C, and the test time is 50 hours. Then with the mass fraction of 5% NaCl+0.1% Na 2 S 2 o 8 The mixed solution is used as the impregnating solution, and the dry-wet test is carried out on the sample in the order of "immersion→drying" in the periodical immersion testing machine, and the cycle is repeated every 30 minutes. The temperature is 40°C, the relative humidity in the testing machine used is 90% RH, and the test time is 50 hours. figure 1 (a) is the surface morphology of the sample after the test. It can be seen that there are obvious pitting pits on the surface of the sample, which is a typical atmospheric corrosion morphology of stainless steel. Figure 4 (a) is the surface topography of the sample after 12 months of outdoor exposure. The comparison shows that the pitting p...

Embodiment 2

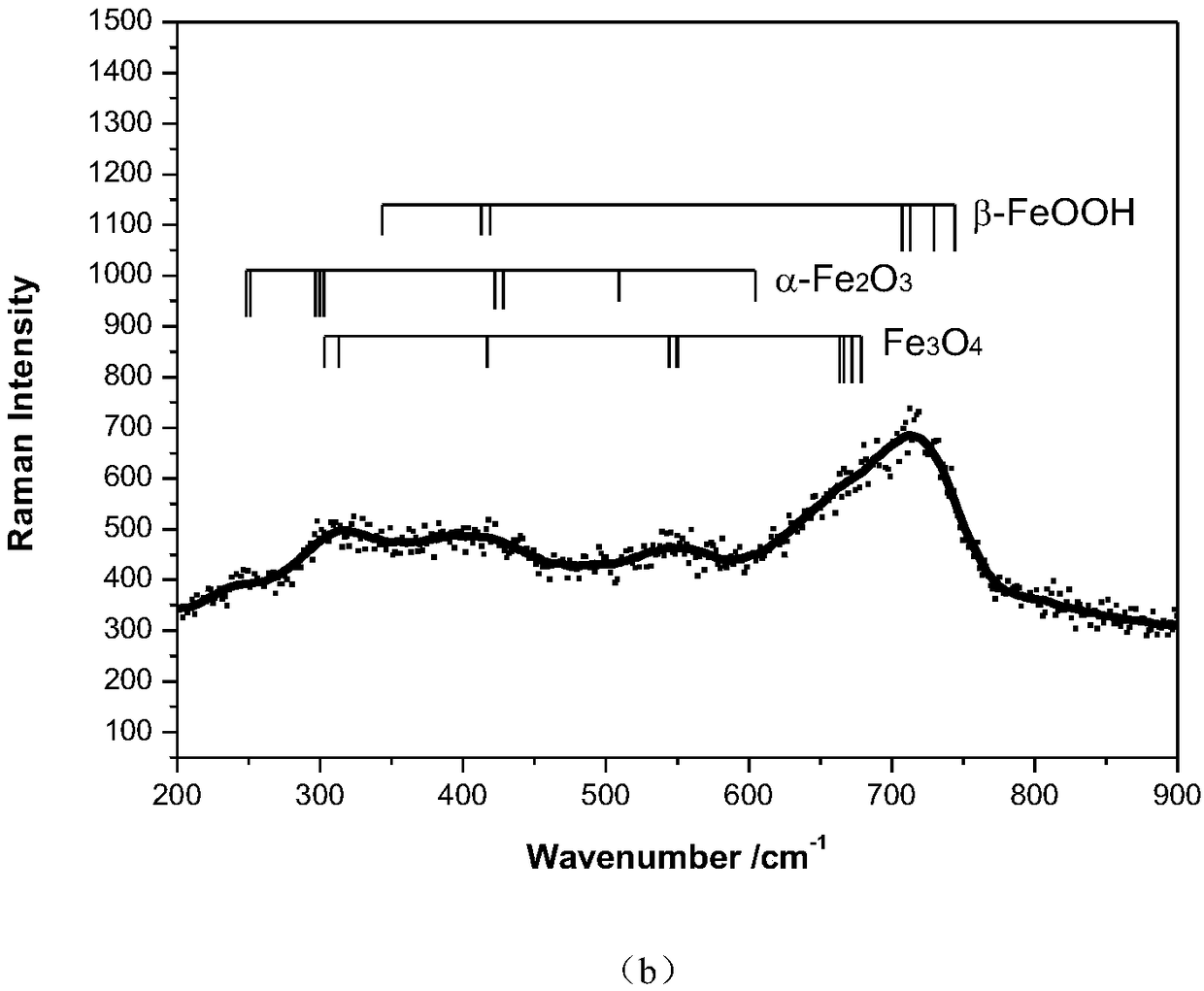

[0046] The experimental material is 316L stainless steel, and the ultraviolet irradiation test is carried out on the sample first, and the irradiation intensity is 60W / m 2 , the temperature is 50°C, and the test time is 50 hours. Then with the mass fraction of 1% NaCl+0.3% Na 2 S 2 o 8 The mixed solution is used as the impregnating solution, and the dry-wet test is carried out on the sample in the order of "immersion→drying" in the periodical immersion testing machine, and the cycle is repeated every 30 minutes. The temperature is 40°C, the relative humidity in the testing machine used is 90% RH, and the test time is 50 hours. The above-mentioned "ultraviolet radiation test + alternating wet and dry test" was carried out for 2 cycles, and the cumulative test time was 200 hours. figure 1 (b) is the topography of the sample surface after the test. It can be seen that there are obvious pitting pits on the surface of the sample, which is a typical atmospheric corrosion morphol...

Embodiment 3

[0048] The experimental material is 316L stainless steel, and the ultraviolet irradiation test is carried out on the sample first, and the irradiation intensity is 60W / m 2 , the temperature is 50°C, and the test time is 50 hours. Then with the mass fraction of 3% NaCl+0.25% Na 2 S 2 o 8 The mixed solution is used as the impregnating solution, and the dry-wet test is carried out on the sample in the order of "immersion→drying" in the periodical immersion testing machine, and the cycle is repeated every 30 minutes. The temperature is 40°C, the relative humidity in the testing machine used is 90% RH, and the test time is 50 hours. The above-mentioned "ultraviolet radiation test + alternating wet and dry test" was carried out for 4 cycles, and the cumulative test time was 400 hours. image 3 It is the change diagram of the corrosion weight loss of the sample after each cycle of the test, and the regression analysis is carried out on the data of the corrosion weight loss of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com