Denitrition catalyst with mercury removal effect and its preparation method

A denitration catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of blocking air preheaters, corroding downstream equipment, increasing cleaning frequency, etc., to reduce corrosion, reduce Treatment cost, effect of improving denitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

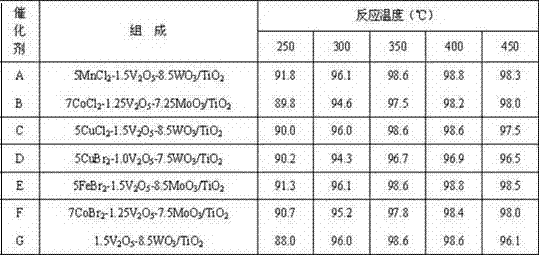

Examples

Embodiment 1

[0033] Embodiment 1 Preparation of catalyst of the present invention

[0034] The preparation method is as follows:

[0035] (1) Add 1.75 times the weight of deionized water to titanium dioxide, mix evenly, heat at 60°C for 24 hours, dry at 80-100°C for 8 hours, and then heat at 120°C for 72 hours, after grinding and sieving, take 60-100 mesh particles to obtain the pre- Activated titanium dioxide.

[0036] (2) Weigh ammonium vanadate with a vanadium content of 1.5 parts by weight, and ammonium tungstate with a tungsten content of 8.5 parts by weight, mix the two, dissolve them in deionized water, and add the pre-activated The carrier titanium dioxide is 65-90 parts by weight, heated and stirred at 60-80°C, so that it is impregnated in the TiO 2 Surface, until the water evaporates, put it in an oven and dry it at 100-110°C for 8 hours.

[0037] (3) Heat up to 400-500°C at a rate of 10-30°C / min, take it out after 5 hours of calcination, cool and grind to obtain SCR catalyst ...

Embodiment 2

[0040] Embodiment 2 Preparation of catalyst of the present invention

[0041] Follow these steps:

[0042] (1) Titanium dioxide activation steps are the same as in Example 1

[0043] (2) Weigh ammonium vanadate containing 1.25 parts by weight of vanadium element and ammonium molybdate of 7.5 parts by weight molybdenum element, mix the two, dissolve with deionized water, add 65-90 parts by weight of pre-activated carrier titanium dioxide, 60-90 parts by weight Heat and stir at 80°C to impregnate TiO 2 Surface, until the water evaporates, put it in an oven and dry it at 100-110°C for 12 hours.

[0044] (3) Heat up to 400-500°C at a rate of 10-30°C / min, take it out after roasting for 5 hours, cool and grind to obtain SCR denitrification catalyst 1.25V 2 o 5 -7.5MoO 3 / TiO 2 , Pressed into 20 ~ 40 mesh particles.

[0045] (4) Weigh cobaltous chloride CoCl containing 7 parts by weight of cobalt element 2 ·6H 2 O, dissolve with appropriate amount of deionization, add SCR ca...

Embodiment 3

[0047] The preparation of embodiment 3 catalysts of the present invention

[0048] (1) Purchase the SCR denitrification catalyst V for coal-fired power plants customized according to the following weight ratio from the supplier 2 o 5 -WO 3 / TiO 2 : 1.5 parts by weight of element V, 8.5 parts by weight of element W, TiO 2 It is 65~90 parts by weight, then through the following steps:

[0049] (2) Weigh cuprous chloride CuCl containing 5 parts by weight of Cu element 2 2H 2 O was dissolved in an appropriate amount of deionized water, added to a commercial SCR denitrification catalyst, fully mixed and impregnated at room temperature until the water evaporated.

[0050] (3) will be impregnated with CuCl 2 The commercial SCR denitration catalyst was moved into a drying oven and dried at 50°C for 24h.

[0051] (4) will be impregnated with CuCl 2 The dried commercial SCR catalyst is placed in a tube furnace, protected by nitrogen, and roasted at 300-350°C for 3 hours at a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com