Nickel base alloy powder, corresponding corrosion-resisting coating and preparing method thereof

A technology of corrosion-resistant coatings and nickel-based alloys, applied in metal material coating processes, coatings, etc., can solve problems such as inability to meet high-temperature concentrated sulfuric acid corrosion and process requirements, and reduce equipment manufacturing costs. promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The substrate material selected for laser cladding in this embodiment is 304 stainless steel. The chemical composition of nickel-based alloy powder for laser cladding is: Cr: 30.00%; Fe: 17%; Mo: 3.50%; Si: 3.00%; Mn: 3.00%; Cu: 3.00%; Ti: 3.00%; B : 0.5%; Ni: balance. The surface of the stainless steel is polished with sandpaper, the surface roughness is Ra=0.2μm, and it is cleaned with acetone before cladding. Using semiconductor lasers, the selected laser cladding process parameters are: power: 800~3000W, focal length: 320~400mm, spot size: 2×4mm, scanning speed: 1mm / s~3mm / s, powder placement thickness: 1.0~ 2.0mm.

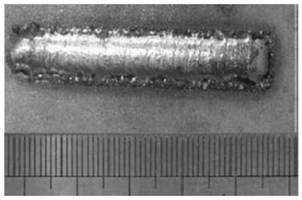

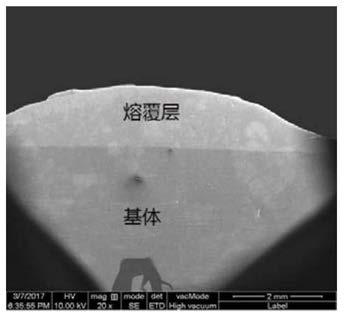

[0033] After laser cladding, such as figure 1 As shown, the surface of the cladding layer is flat, without macroscopic defects such as pores and cracks, and the hardness is HRC63. The microscopic appearance of the cladding layer is as figure 2 As shown in the figure, it can be seen that the cladding layer is well bonded to the substrate, and the clad...

Embodiment 2

[0040] The substrate used in this embodiment is a ball valve made of 304 stainless steel. The chemical composition of the alloy powder is: Cr: 30.00%; Fe: 17%; Mo: 3.50%; Si: 3.00%; Mn: 3.00%; Cu: 3.00%; Ti%: 3.00%; B: 0.5%; Ni: margin. The surface of the sphere is polished with sandpaper, and the surface roughness is Ra=0.2 μm, and it is cleaned with acetone before cladding. Using semiconductor lasers, the selected laser cladding process parameters are: power: 800~3000W, focal length: 320~400mm, spot size: 2×4mm, scanning speed: 1mm / s~3mm / s, powder thickness: 0.5~ 1.5mm. After laser cladding, the surface is turned, and the samples after cladding are as follows: Figure 5 As shown, the surface of the cladding layer is smooth and dense, without macroscopic defects such as pores and cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com