Three-layer membrane for lithium ion battery

A lithium-ion battery and separator technology, which is applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high closed-cell temperature, the composite separator does not have high temperature resistance, and it is difficult to apply coatings, so as to ensure the protection and durability. Temperature performance and mechanical strength, guaranteed stability and tear strength, guaranteed peel strength and effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

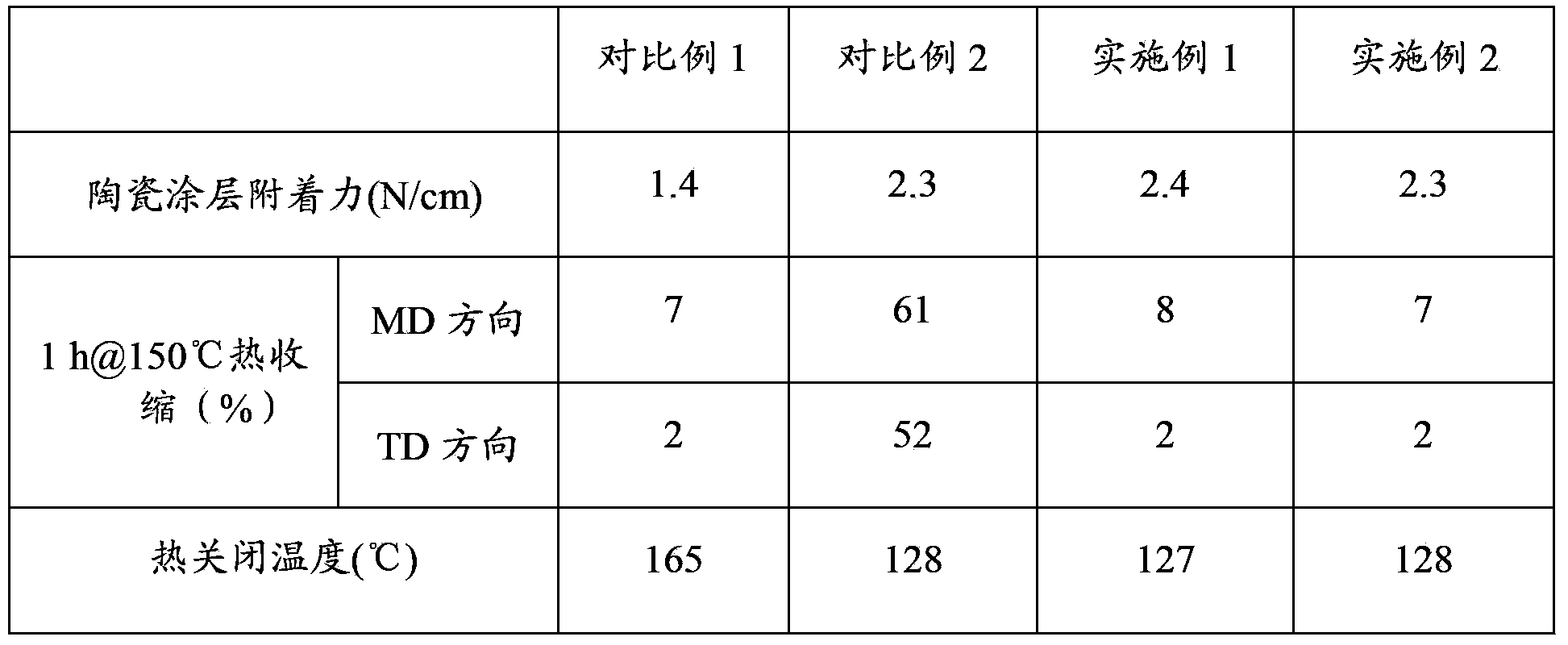

[0025] The structure of the three-layer separator used in the lithium ion battery in this example is as follows figure 1 As shown, it includes a polypropylene diaphragm layer 1, a ceramic coating 3, and a polyethylene diaphragm layer 2 sandwiched between the polypropylene diaphragm layer 1 and the ceramic coating 3. The specific preparation method includes hot-press laminating a polypropylene diaphragm with a thickness of 10 μm and a polyethylene diaphragm with a thickness of 10 μm, and then coating a ceramic coating with a thickness of 5 μm on the surface of the polyethylene diaphragm to form the composite diaphragm of the present application. And test the adhesion of the ceramic coating, the heat shrinkage rate of heating at 150°C for 1 hour, and the thermal shutdown temperature. The test results are shown in Table 1.

Embodiment 2

[0027] The structure of the three-layer separator for lithium-ion batteries in this example is the same as that of Example 1, except that the preparation method is changed. Specifically, a polypropylene / polyethylene composite base film with a thickness of 22 μm is prepared by a co-extrusion method. After the Celgard dry process is stretched into holes, a 5μm ceramic coating is applied to the polyethylene surface to make the composite diaphragm of this application, and the ceramic coating adhesion is tested, the heat shrinkage rate of heating at 150°C for 1 hour, and the heat Turn off the temperature. The test results are shown in Table 1.

[0028] Table 1 Performance test of composite diaphragm

[0029]

[0030] According to the test results in Table 1, it can be seen that compared with Comparative Example 1, the three-layer separator for lithium ion batteries of the present application overcomes the problem of low adhesion and easy shedding of the ceramic coating in the polypropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com