Automatic hot melt adhesive spraying device for screen cloth

A technology of hot-melt adhesive and hot-melt glue machine, which is applied to the device and coating of the surface coating liquid, can solve the problems of no surface, uneven glue quantity, streaks on the sprayed surface, etc., to reduce manpower effects of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

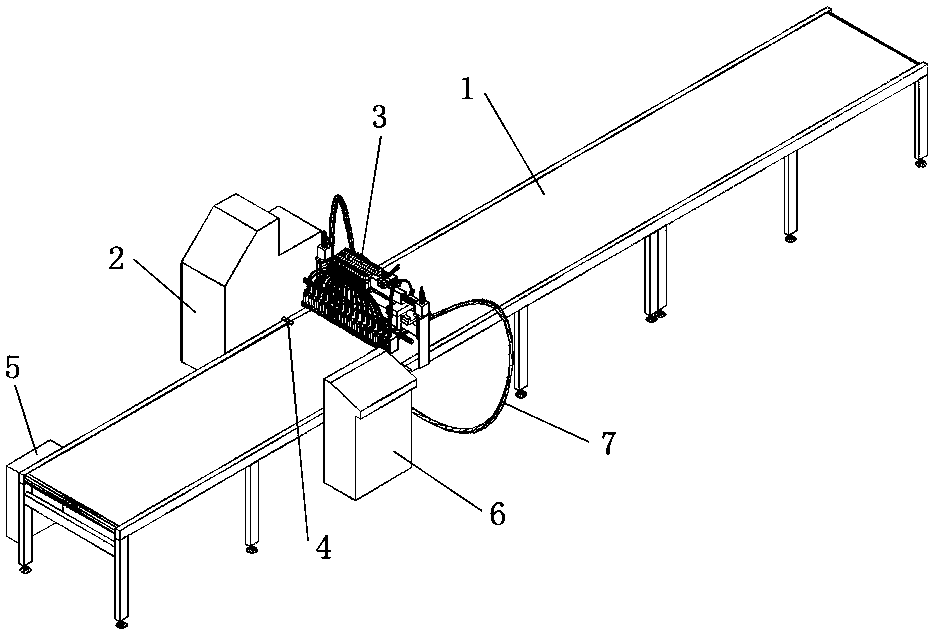

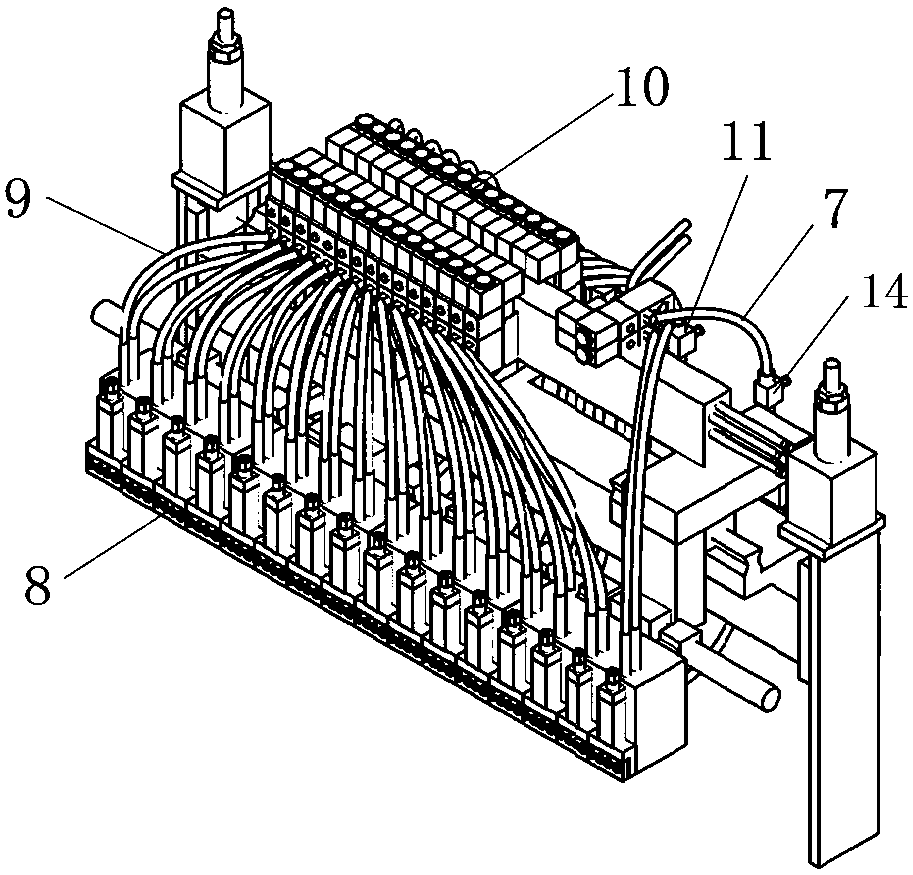

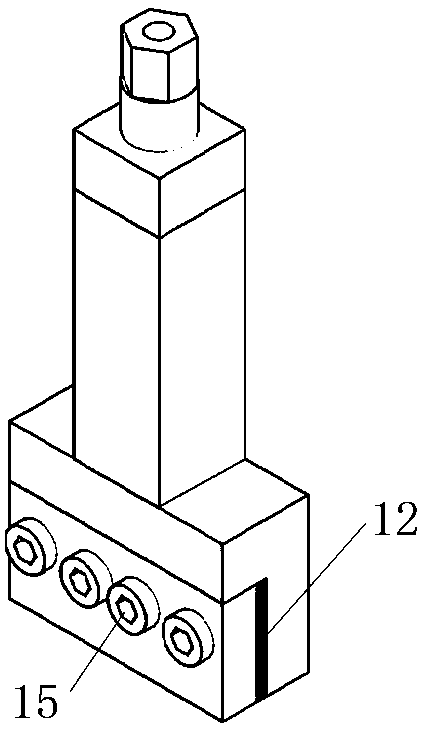

[0020] As shown in the accompanying drawings, a device for automatically spraying hot-melt glue on screen fabrics, including a conveyor belt 1, a hot-melt glue machine 2, a nozzle group 3, an induction device 4, a motor 5 and a control box 6, a hot-melt glue machine 2 and a nozzle The groups 3 are communicated with each other through the rubber hose 7, and the rubber hose 7 is also provided with a pressure control valve 14. The induction device 4 is arranged on the front side of the spray head group 3, and the number of the spray head group is 4 groups, each group includes 4 spray guns 8, and each spray gun 8 is respectively connected to the air pipe 9, the solenoid valve 10 and the air pressure control valve 11 in sequence. The spray gun 8 is provided with 5 spray sheets 12, and the spray sheets 12 are provided with a plurality of glue spray holes 13. The spraying width of the spray gun 8 is 50mm, and the spraying width refers to the maximum width of spraying by the spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com