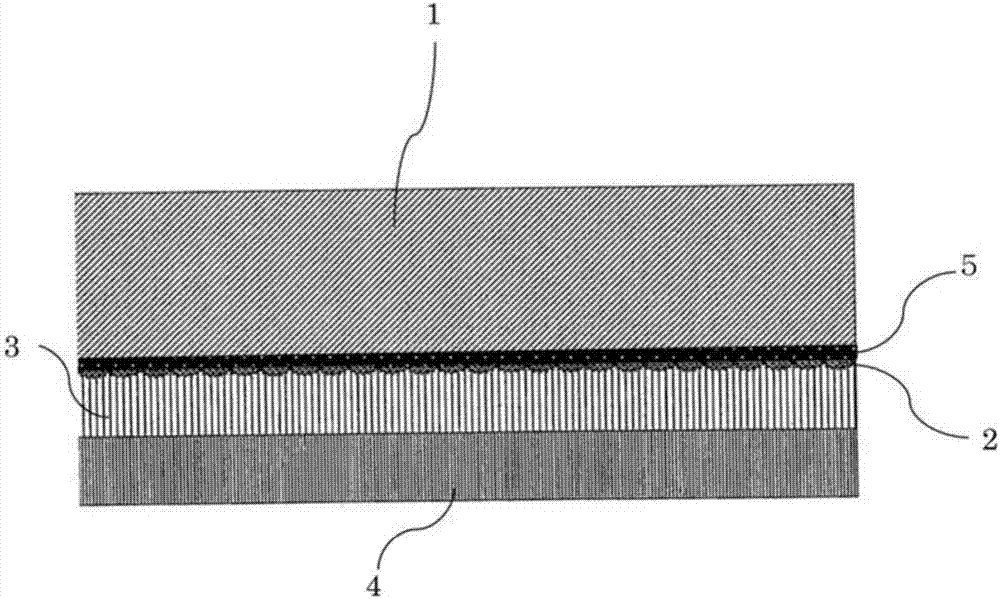

Surface-treated copper foil and printed wiring board using the surface-treated copper foil

A surface treatment, copper foil technology, applied in printed circuit parts, metal pattern materials, layered products, etc., can solve the problem of trivalent chromium oxidation to hexavalent chromium, etc., to achieve no powder falling and maintain peel strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

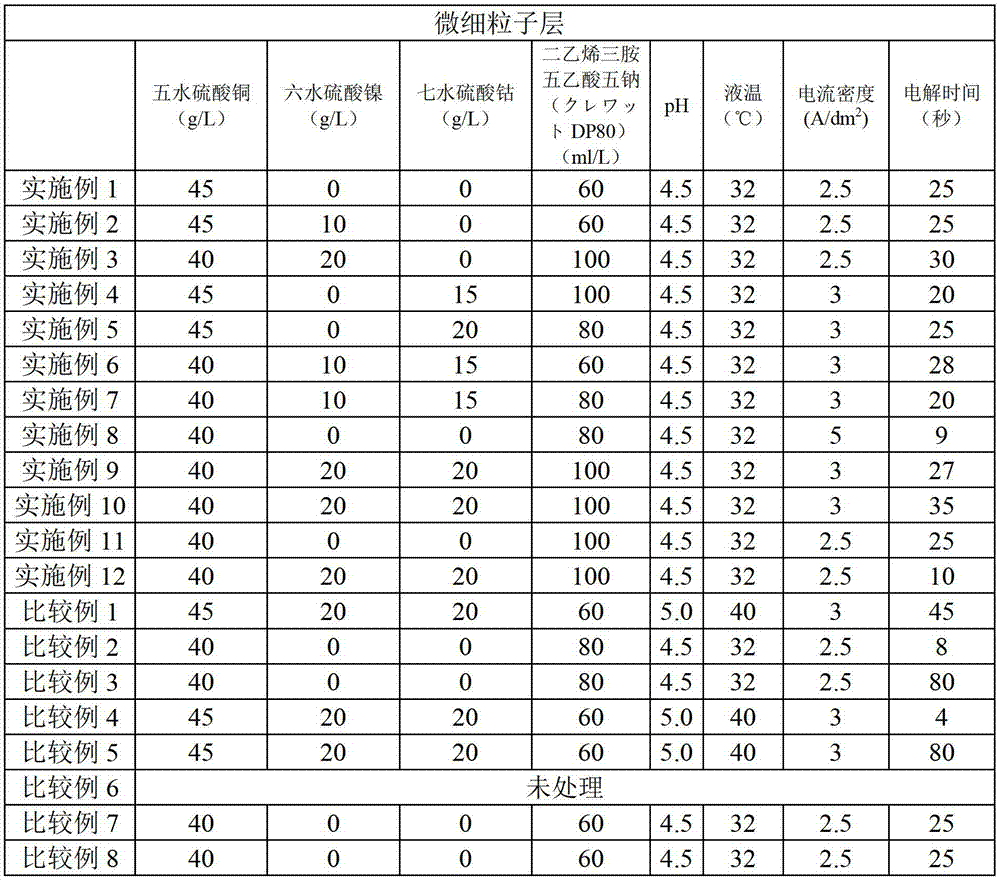

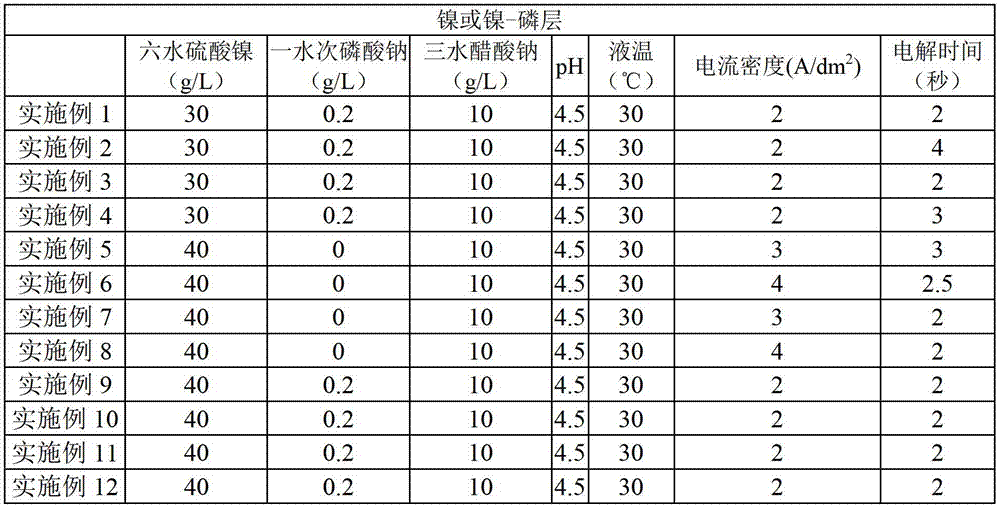

[0072] Examples of the present invention are listed below, but the present invention is not limited by them.

[0073] (roughening treatment)

[0074] A rolled copper foil with a surface roughness RzJIS of 1.1 μm and a thickness of 18 μm is dipped in a mixture of 45 g / L copper sulfate pentahydrate, 100 g / L sulfuric acid, 20 ppm chloride ions, and the liquid temperature is adjusted to 30°C, and then, With platinum as the anode and at a current density of 10A / dm 2 1. Under the condition that the electrolysis time is 12 seconds, the dendritic copper powder is attached to the surface of the rolled copper foil.

[0075] In order to prevent the attached dendritic copper powder from falling off, after immersing in a mixed solution of 250g / L copper sulfate pentahydrate, 100g / L sulfuric acid, and adjusting the liquid temperature to 30°C, platinum was used as the anode and the current density was 5A / dm 2 1. Electrolyzing under the condition that the electrolysis time is 70 seconds, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com