Three-layer flexible copper-clad plate hot baking tray

A flexible copper clad laminate and tray technology, which is used in the improvement of metal adhesion of insulating substrates, secondary processing of printed circuits, electrical components, etc. Guaranteed peel strength, improved product quality, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

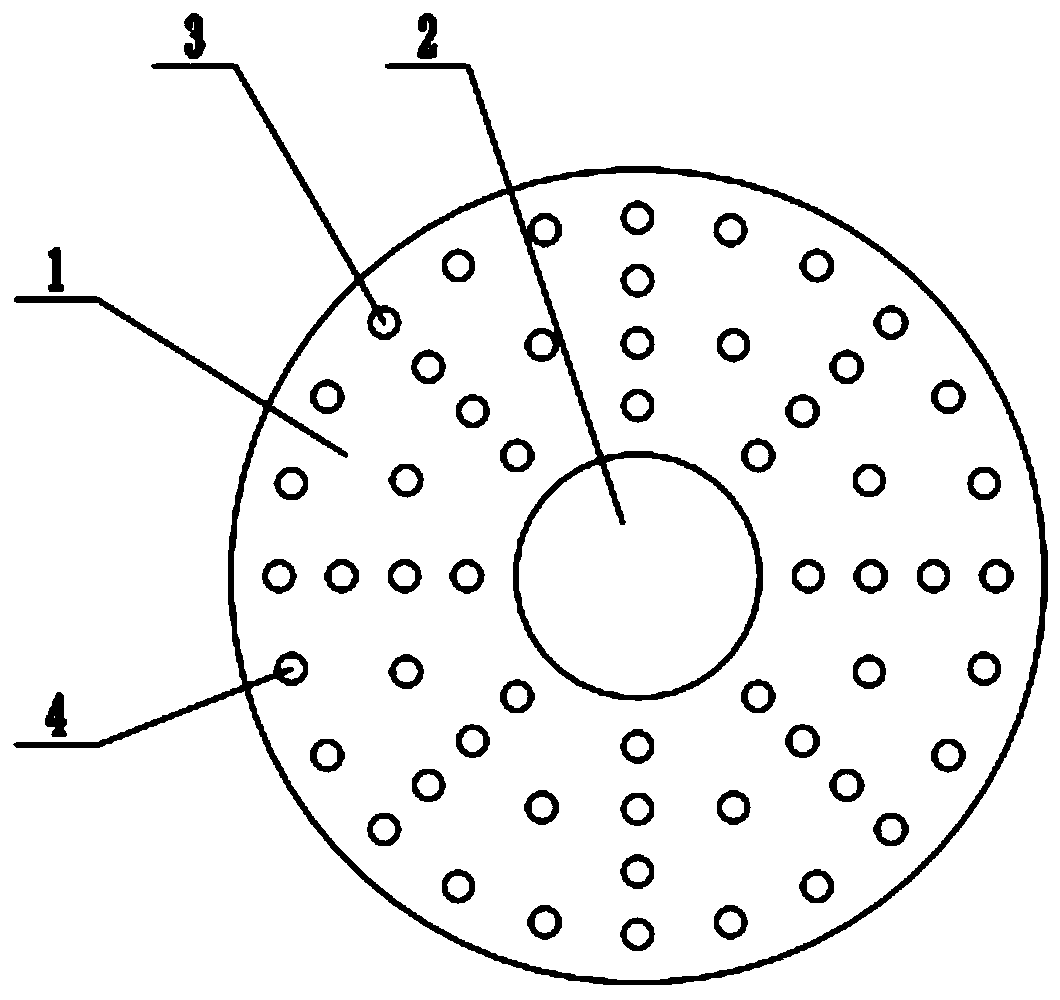

[0025] A three-layer flexible copper-clad laminate thermal baking tray, including a substrate 1, the substrate 1 is a circular plate, the center of the substrate 1 is provided with a main hole 2, and the diameter of the main hole is about 1 / 4-1 / 3 of the diameter of the substrate 3. Several rows of auxiliary holes 3 are provided on the surface of the substrate 1, and each row of the auxiliary holes has 3-6 holes, and the plurality of rows of the auxiliary holes 3 are evenly distributed around the center of the substrate 1. In this embodiment The auxiliary holes in each row are 45°. A group of several clamping holes 4 is arranged between every two adjacent rows of the auxiliary holes 3 . In this embodiment, there are three clamping holes 4, and the three clamping holes 4 are distributed in an isosceles triangle between two rows of auxiliary holes 3, and the clamping hole 4 at the apex of the isosceles triangle is located close to the substrate 1 On the side of the center of the...

Embodiment 2

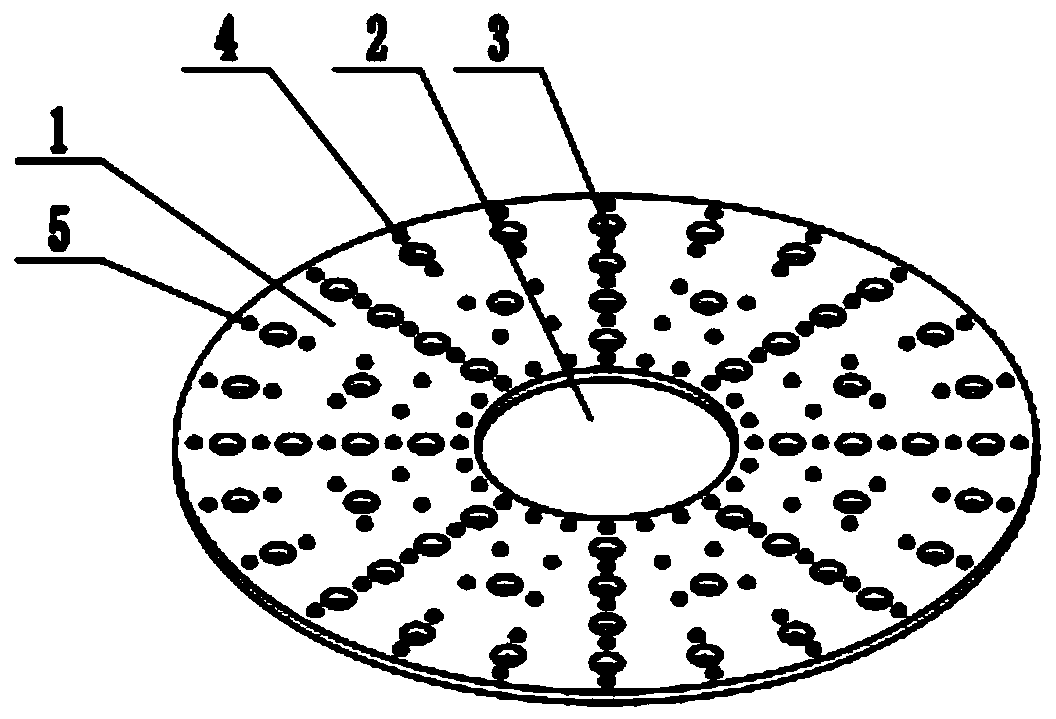

[0028] Based on Embodiment 1, in this embodiment, several protrusions 5 are uniformly arranged on the top surface of the substrate 1 . The protrusions are metal particles or protrusions punched out by spot welding or spot stamping heads.

[0029] The tray described in Example 1 was used to accept the copper-clad laminates for thermal drying, and the average peel strength of the copper-clad laminates obtained from the five groups was 1.62 N / mm.

Embodiment 1 or Embodiment 2

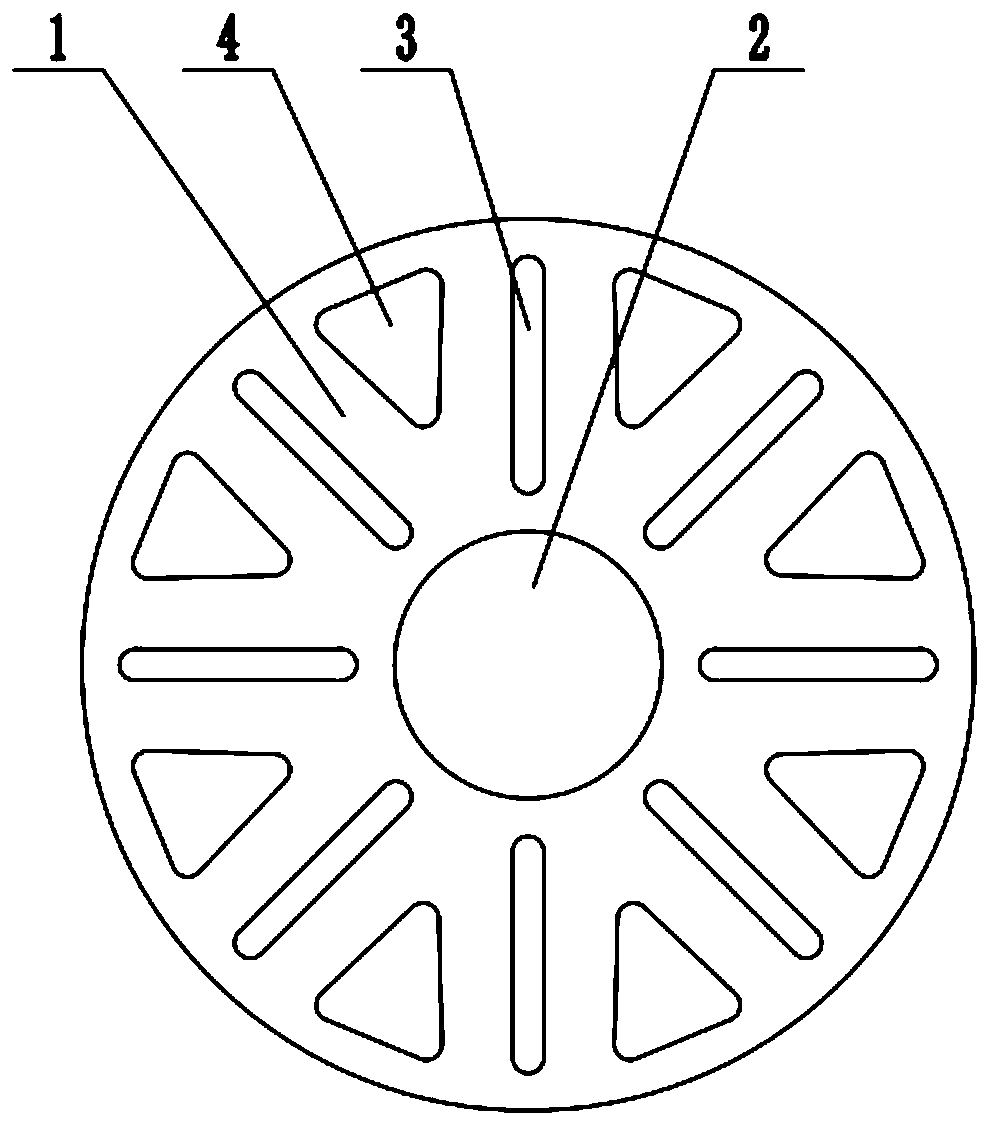

[0031] For embodiment 1 or embodiment 2, the edges of the main hole 2, the auxiliary hole 3 and the clamping hole 4 in this embodiment are punched out toward the bottom surface of the substrate 1 to form a flange 6, and the flange 6 of each hole protrudes to a height of consistent. The flanging causes a gradual depression at the edge position of the front hole of the substrate.

[0032] The tray described in Example 1 was used to accept the copper-clad laminates for thermal drying, and the average peel strength of the copper-clad laminates obtained from the five groups was 1.57 N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com