Two-component temperature-resistant water-based pressure-sensitive adhesive as well as preparation method and application thereof

A pressure-sensitive adhesive, two-component technology, used in adhesives, adhesive types, polyurea/polyurethane adhesives, etc. The effect of improving temperature resistance, increasing crosslinking density, increasing cohesive strength and peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

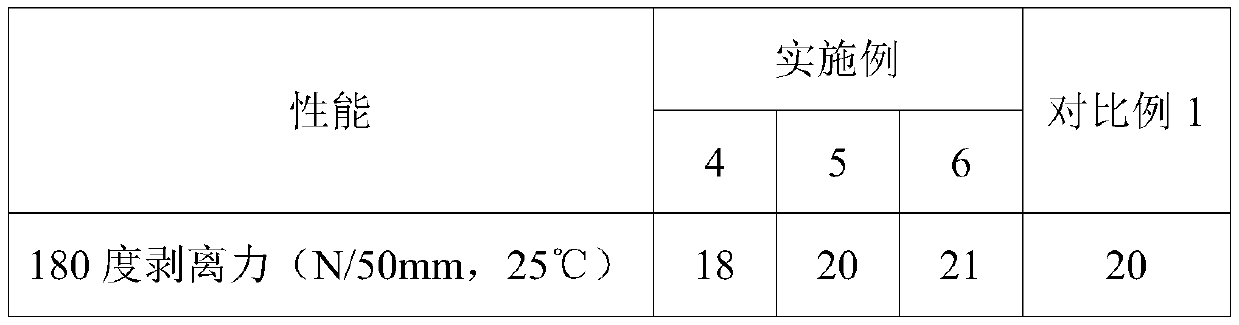

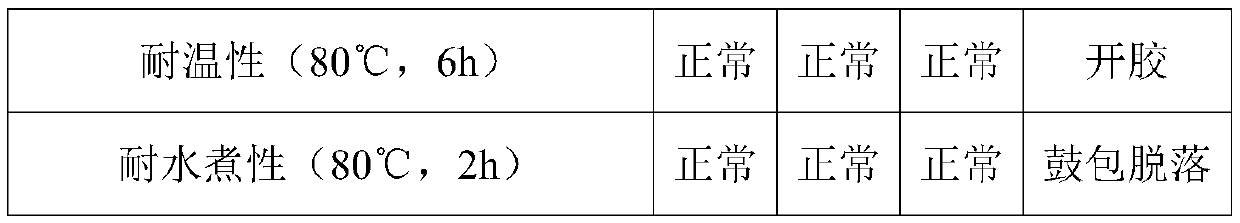

Examples

Embodiment 1

[0029] This embodiment provides a two-component temperature-resistant water-based pressure-sensitive adhesive, the preparation method of which comprises the following steps:

[0030] (1) Weigh 350kg of water-based acrylic pressure-sensitive emulsion, 122.5kg of tackifying resin, 15kg of thickener, 2.5kg of defoamer, 5kg of bactericide, and 5kg of pH regulator, and set aside. Among them, the water-based acrylic pressure-sensitive emulsion is V206AP emulsion of BASF; the viscosity-increasing emulsion is TSR-5100 emulsion of Tongxuan Lixin; the thickener is RM-8W emulsion of Rohm and Haas; the defoamer is silicone defoamer ; Bactericide is methyl isothiazolinone; pH regulator is a mixture of ethanolamine, diethanolamine and 2-amino-2-methyl-1-propanol.

[0031] (2) The above-mentioned water-based acrylic pressure-sensitive emulsion, viscosifying emulsion, defoamer, bactericide and pH regulator are placed in a 600L reactor, stirred at a frequency of 10Hz and dispersed at a frequen...

Embodiment 2

[0035] This embodiment provides a two-component temperature-resistant water-based pressure-sensitive adhesive, the preparation method of which comprises the following steps:

[0036] (1) Weigh 468.5kg of water-based acrylic pressure-sensitive emulsion, 25kg of viscosifying emulsion, 5kg of thickener, 0.5kg of defoamer, and 1kg of bactericide, and set aside. Among them, the water-based acrylic pressure-sensitive emulsion is BLJ-509 emulsion of Shanghai Polyjia; the viscosity-increasing emulsion is TSR-1650 polymerized rosin emulsion of Tongxuan Lixin; the softening point of polymerized rosin emulsion is 160 ° C; the thickener is hydroxymethyl cellulose A mixture of plain and alkali-swellable acrylic emulsion (Rohm and Haas TT-935 emulsion); the defoamer is a polyether defoamer; the fungicide is methylchloroisothiazolinone and 1,2-benzisothiazole Mixtures in lin-3-ones.

[0037] (2) The above-mentioned water-based acrylic pressure-sensitive emulsion, viscosifying emulsion, defo...

Embodiment 3

[0041] This embodiment provides a two-component temperature-resistant water-based pressure-sensitive adhesive, the preparation method of which comprises the following steps:

[0042](1) Weigh 420.5 kg of water-based acrylic pressure-sensitive emulsion, 60 kg of viscosifying emulsion, 10 kg of thickener, 1.5 kg of defoamer, 4 kg of bactericide, and 4 kg of pH regulator, and set aside. Among them, the water-based acrylic pressure-sensitive emulsion is BLJ-509 emulsion of Shanghai Polyjia; the viscosity-increasing emulsion is TSR-5901 terpene phenol resin emulsion of Tongxuan Lixin; the thickener is hydroxymethyl cellulose; the defoaming agent is polyether Modified silicone defoamer; fungicide is a mixture of methylisothiazolinone, methylchloroisothiazolinone and 1,2-benzisothiazolin-3-one; pH regulator is triethanolamine and ammonia mixture.

[0043] (2) The above-mentioned water-based acrylic pressure-sensitive emulsion, viscosifying emulsion, defoamer, bactericide and pH regu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com