Preparation method for ferrite/reductive metal composite particles and method for preparing high-temperature invisible coating layers based on laser 3D printing

A metal composite and 3D printing technology, applied in metal processing equipment, process efficiency improvement, additive manufacturing, etc., can solve the problems of unguaranteed electromagnetic performance, difficult to control microstructure, film layer/substrate bonding force, etc., achieving significant advantages , Satisfactory tissue properties, dense and complete coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

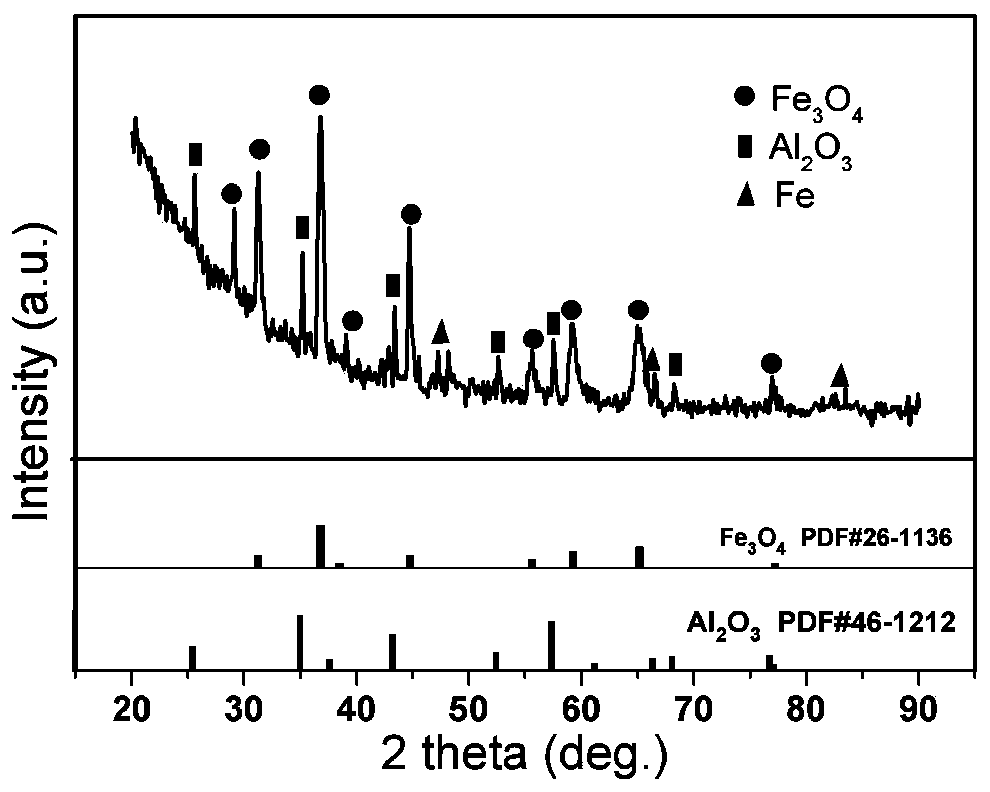

[0035] Embodiment 1: The preparation method of the ferrite / reducing metal composite particles used in this example is prepared by a mixing and granulation process, and the specific preparation method is completed through the following steps:

[0036] Step 1, the particle size diameter is 80nm, spherical Fe 3 o 4 Particles, particle size diameter of 50nm, spherical Al particles and polyvinyl alcohol (PVA) additives according to Fe 3 o 4 The mass ratio to Al is 3.2:1, and the additive dosage is 0.5% of the total mass of the ferrite powder and the reducing metal powder to uniformly mix to obtain a slurry;

[0037] Step 2. The obtained slurry is granulated by centrifugal spray drying and granulation; the spray drying process parameters are as follows: the inlet temperature of the spray drying tower is 220°C, the outlet temperature of the spray drying tower is 100°C, and the spray drying tower is atomized The rotational speed of the disk was 20000r / min. After the granulation is...

Embodiment 2

[0052] Embodiment 2: In this embodiment, the method for preparing a high-temperature stealth coating based on laser 3D printing is carried out according to the following steps:

[0053] The preparation method of the ferrite / reducing metal composite particles used in this example is prepared by a mixing and granulation process, and the specific preparation method is completed through the following steps:

[0054] Step 1, the particle size diameter is 100nm, spherical BaFe 12 o 19 Particles, particle size diameter of 50nm, spherical Al particles and additives (methyl cellulose (CMC)) according to BaFe 12 o 19 The mass ratio of particles to Al particles is 3.2:1, the amount of additives is 1% of the total mass of ferrite powder and reducing metal powder, and the slurry is obtained after uniform mixing;

[0055] Step 2. The obtained slurry is granulated by centrifugal spray drying and granulation; the spray drying process parameters are: the inlet temperature of the spray dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com