Solid phase micro-extraction fiber, and preparation method and use thereof

A technology for extracting fibers and stainless steel wires, which is applied in separation methods, chemical instruments and methods, and other chemical processes, and can solve the problem of affecting the enrichment effect and service life of solid phase microextraction fibers and increasing the difficulty of solid phase microextraction fiber processes , solid phase microextraction fiber performance adverse effects and other issues, to achieve good extraction capacity, improve adsorption capacity and performance, porosity and good extraction capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 Preparation of solid-phase microextraction fiber of the present invention

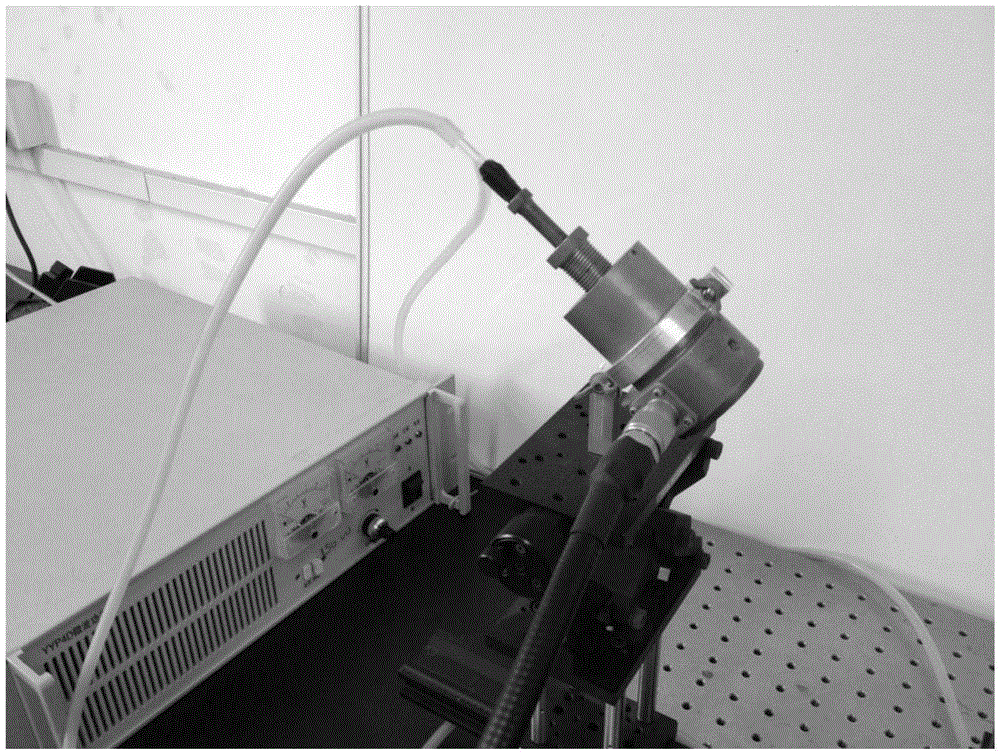

[0073] a. Select a stainless steel wire with a length of 100 mm and a diameter of 0.15 mm, and use acetone, methanol, and deionized water to ultrasonically clean it for 30 minutes. The stainless steel wire is microwave-induced plasma (microwave-induced plasma device, such as figure 1 Shown) uniform treatment for 5min, put into the desiccator for later use.

[0074] Microwave-Induced Plasma Treatment: Select the Surfatron chamber (see figure 1 ) is a microwave-induced plasma generation cavity, and the central axis of the copper cavity is a fused silica tube as a plasma generator. The argon flow is first introduced into the quartz tube, and the argon plasma is ignited under the action of the microwave source. After the argon plasma is stable, the compressed air flow is slowly introduced. The ratio of the flow rate of the argon flow to the air flow is 0.25~0.30:0.05~0.1( In this imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com