Corrosion-resistant pump made from carbon/carbon composite materials

A carbon composite material and corrosion-resistant pump technology, which is applied to pumps for special fluids, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as affecting popularization and application, narrow corrosion resistance range, and affecting service life. , to achieve the effect of simple forming process, good airtightness and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

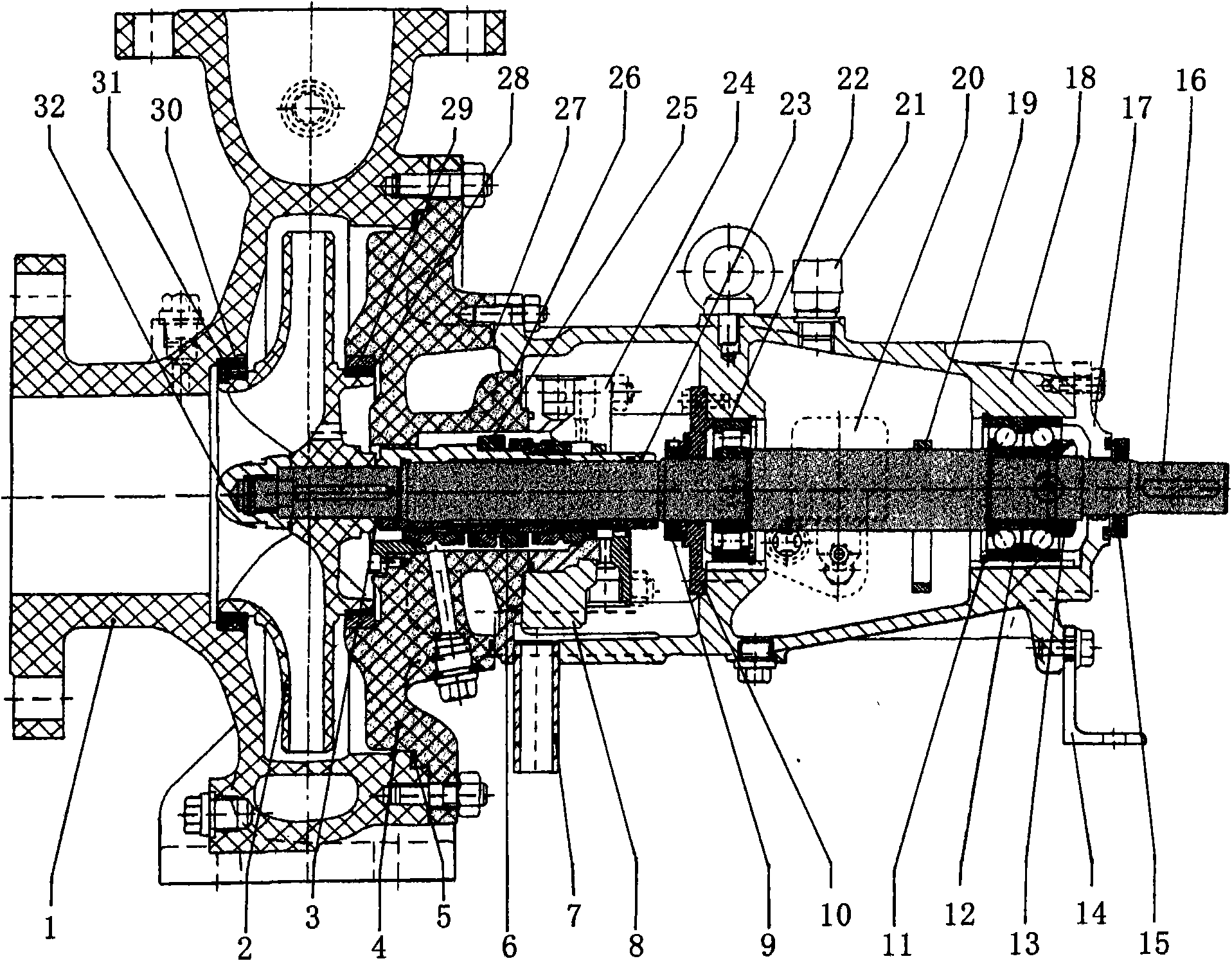

[0014] figure 1 In the schematic structural diagram of a corrosion-resistant pump made of carbon / carbon composite material shown, the device includes a pump body 1, an impeller 2, a first flat sealing gasket 3, a pump cover 4, a second flat sealing gasket 5, Mechanical seal (double seal) 6, drain pipe 7, sealing cover (double seal) 8, front baffle plate 9, front bearing cover 10, retaining ring 11, first rolling bearing 12, bearing nut 13, support foot 14, rear folding Flow plate 15, shaft 16, rear bearing cover 17, bearing frame 18, oil throwing ring 19, constant level oil cup 20, oil separator 21, second rolling bearing 22, shaft sleeve 23, sealing cover (single seal) 24, mechanical Seal (single seal) 25, first O-ring seal 26, second O-ring seal 27, first impeller mouth ring 28, pump cover mouth ring 29, second impeller mouth ring 30, pump body mouth ring 31, impeller The nuts 32 are connected to each other and combined to form the present invention.

[0015] The corrosion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com