High-throughput preparation method of high-temperature titanium alloy material based on laser in-situ metallurgy

A high-temperature titanium alloy, in-situ metallurgy technology, applied in the improvement of process efficiency, additive manufacturing, additive processing and other directions, can solve problems such as restricting the efficiency of research and design of new high-temperature titanium alloys, achieve easy screening and optimization design, and ensure consistency , to ensure the effect of forming consistency

Active Publication Date: 2021-11-19

北京煜鼎增材制造研究院有限公司

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional smelting, casting and forging processes have great difficulties in controlling the uniform composition and impurity content, and can only prepare alloys with one composition ratio at a time, which seriously restricts the development and design efficiency of new high-temperature titanium alloys.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Login to View More

Abstract

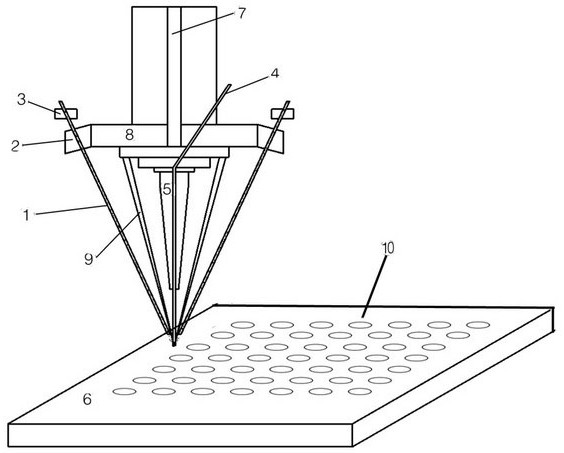

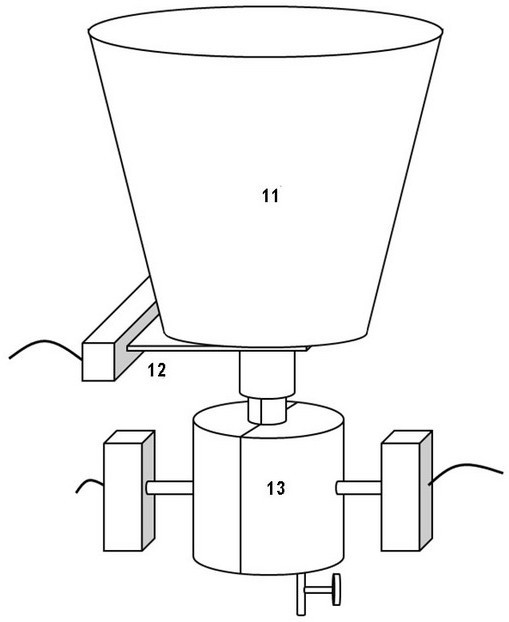

The invention provides a high-throughput preparation method of a high-temperature titanium alloy material based on laser in-situ metallurgy. The method comprises the following steps: 1) taking a titanium alloy as a basic component, doping rare earth and / or a high-melting-point element, and designing a novel high-temperature titanium alloy with various component proportions at one time; (2) symmetrically arranging a plurality of lateral powder feeding heads and a plurality of independent powder flow monitoring modules in one-to-one correspondence with the lateral powder feeding heads on the periphery of an output mirror of a coaxial wire feeding laser machining head for wire feeding and powder feeding; (3) carrying out wire feeding and powder feeding according to the configured wire feeding speed and powder feeding speed, simultaneously starting a laser device, enabling high-energy ring laser beams to fuse the wires and the powder in situ according to at least one set of preset technological parameters, and carrying out high-throughput forming to obtain massive cast ingots of the novel high-temperature titanium alloy with the different component proportions; and (4) carrying out high-temperature compression test on the cast ingots of the high-temperature titanium alloy to determine the compressive strength, and optimally designing the components of the high-temperature titanium alloy according to the compressive strength.

Description

technical field [0001] The invention relates to laser additive manufacturing products and methods, in particular to a high-throughput preparation method of high-temperature titanium alloy materials based on laser in-situ metallurgy. Background technique [0002] High-temperature titanium alloy has excellent high-temperature mechanical properties and high-temperature oxidation resistance, especially in the harsh working conditions of high temperature, high speed, and high pressure when the aeroengine is running, it can take into account high temperature performance and high thrust-to-weight ratio, and is an indispensable part of the aerospace field. a structural material. The United States, Russia, and the United Kingdom have all established their own high-temperature titanium alloy systems. my country has also independently developed Ti60, Ti600 and other alloys from the initial imitation, and its long-term service temperature can reach 600°C. 600°C is also considered to be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22F10/20B22F10/25B22F10/85C22C14/00C22C1/04B33Y10/00B33Y50/02

CPCB22F10/20B22F10/25B22F10/85C22C14/00C22C1/0458B33Y10/00B33Y50/02Y02P10/25

Inventor 不公告发明人

Owner 北京煜鼎增材制造研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com