A Method for Establishing Constitutive Model for Rolling Simulation of gh4169 Material

A GH4169, constitutive model technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve problems such as large deformation and affecting the accuracy of numerical simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

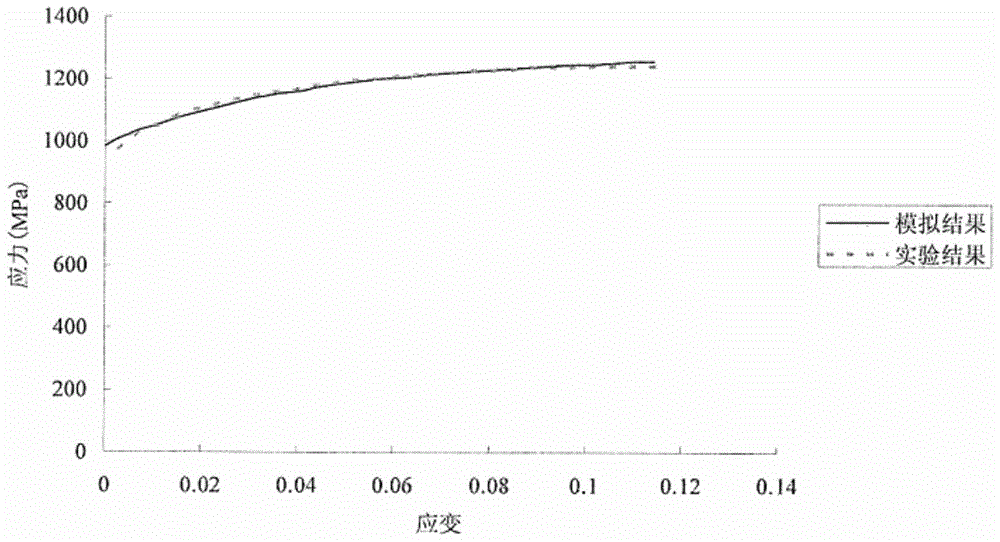

[0054] 1) Monotonic tensile test of GH4169 alloy

[0055] In order to obtain the monotonic drawing performance of GMI69 alloy at room temperature, the material was taken from the cold-drawn bar of GH4169 alloy and processed into with The standard tensile specimens were subjected to static tensile tests. The experimental conditions are shown in Table I.

[0056] Table 1 Experimental Conditions of Tensile Experiment

[0057] Experimental conditions Tensile test one Tensile test two Sample size Φ8mm Φ5mm Strain rate 4.8mm / min, 3.2mm / min, 1.6mm / min 3mm / min, 2mm / min, 1mm / min temperature room temperature room temperature Strain range Stretch until the specimen breaks Stretch until the specimen breaks Laboratory equipment WDS-100 electronic universal testing machine AG-IS 50kN Universal Testing Machine

[0058] 2) Low cyclic strain controlled symmetric loading experiment of GH4169 alloy

[0059] Processing GH4169 al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com