AMOLED (active matrix organic light emitting diode) and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as low luminous efficiency, achieve high luminous efficiency, high stability, and improve the effect of electron injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

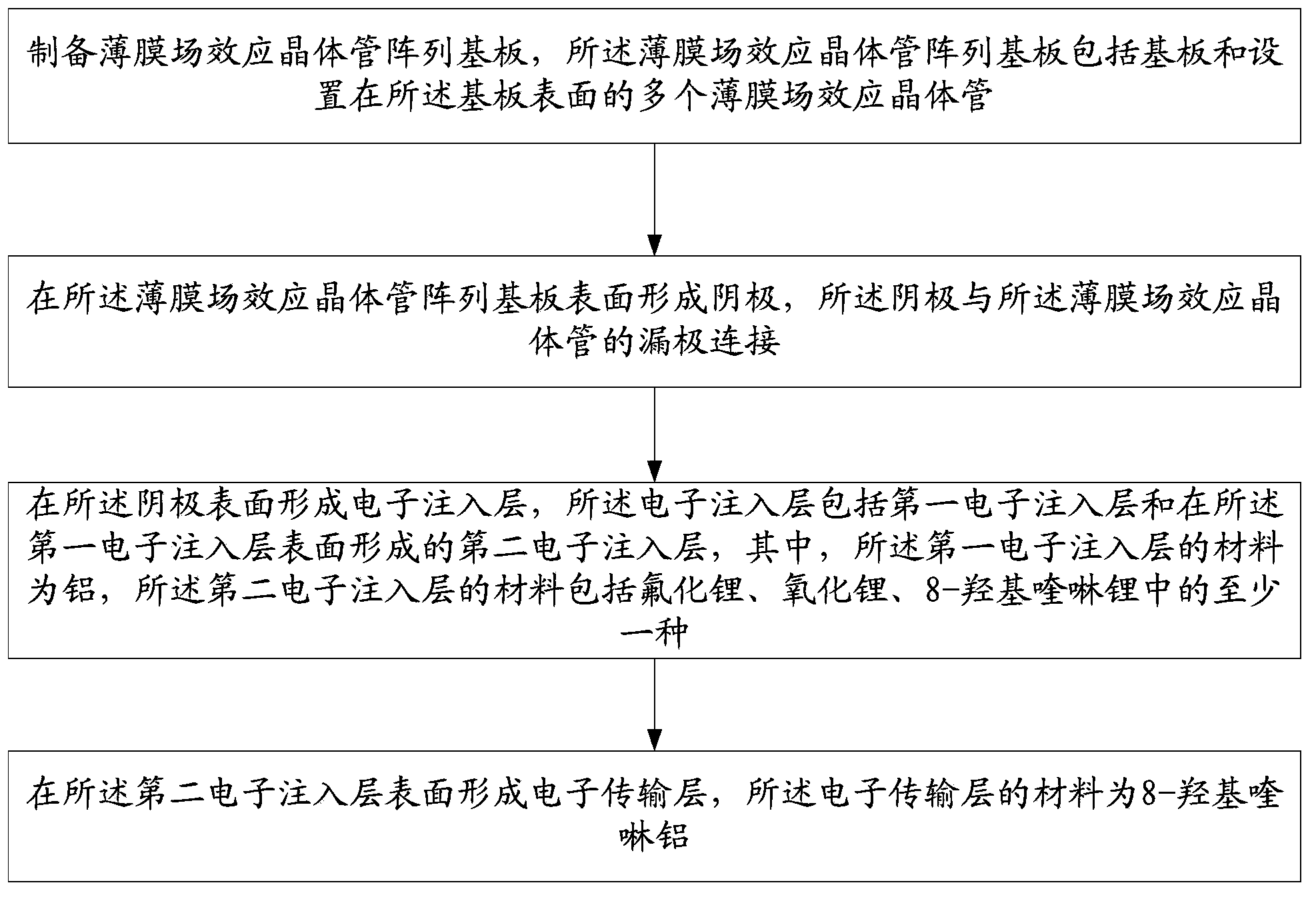

[0044] This embodiment provides a method for manufacturing an active matrix organic light emitting diode panel, such as figure 2 As shown, the method includes:

[0045] preparing a thin film field effect transistor array substrate, the thin film field effect transistor array substrate comprising a substrate and a plurality of thin film field effect transistors arranged on the surface of the substrate;

[0046] One of the formation methods of a single TFT is: first form a gate on the substrate, then form a gate insulating layer or an etching barrier layer that completely covers the gate on the gate, and then form a gate insulating layer or an etching barrier layer on the surface of the gate insulating layer or etching barrier layer. An active layer is formed on the active layer, and then a source electrode and a drain electrode are formed on the active layer, and finally a passivation layer is covered on the source electrode and the drain electrode, and a drain contact hole ex...

Embodiment 2

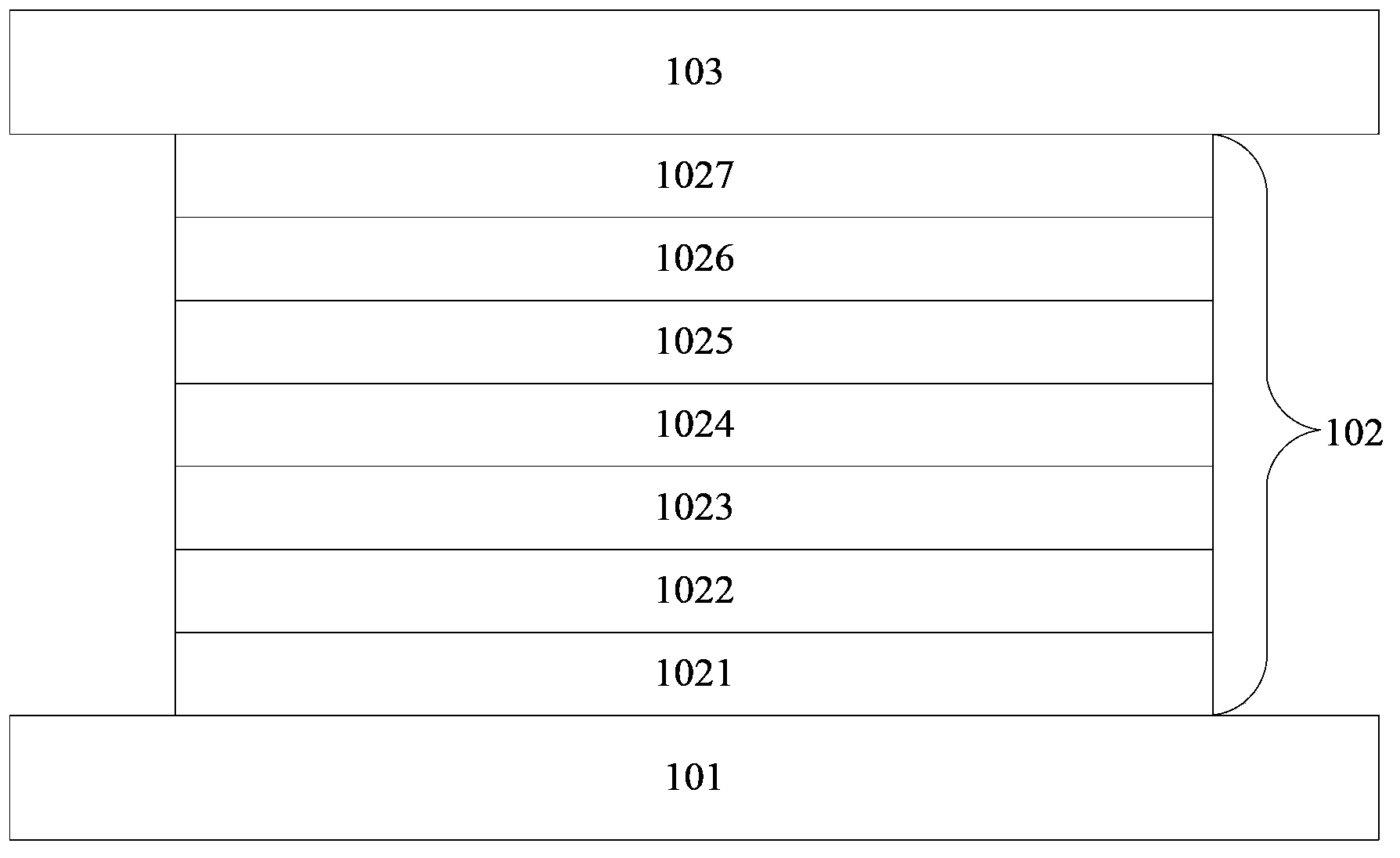

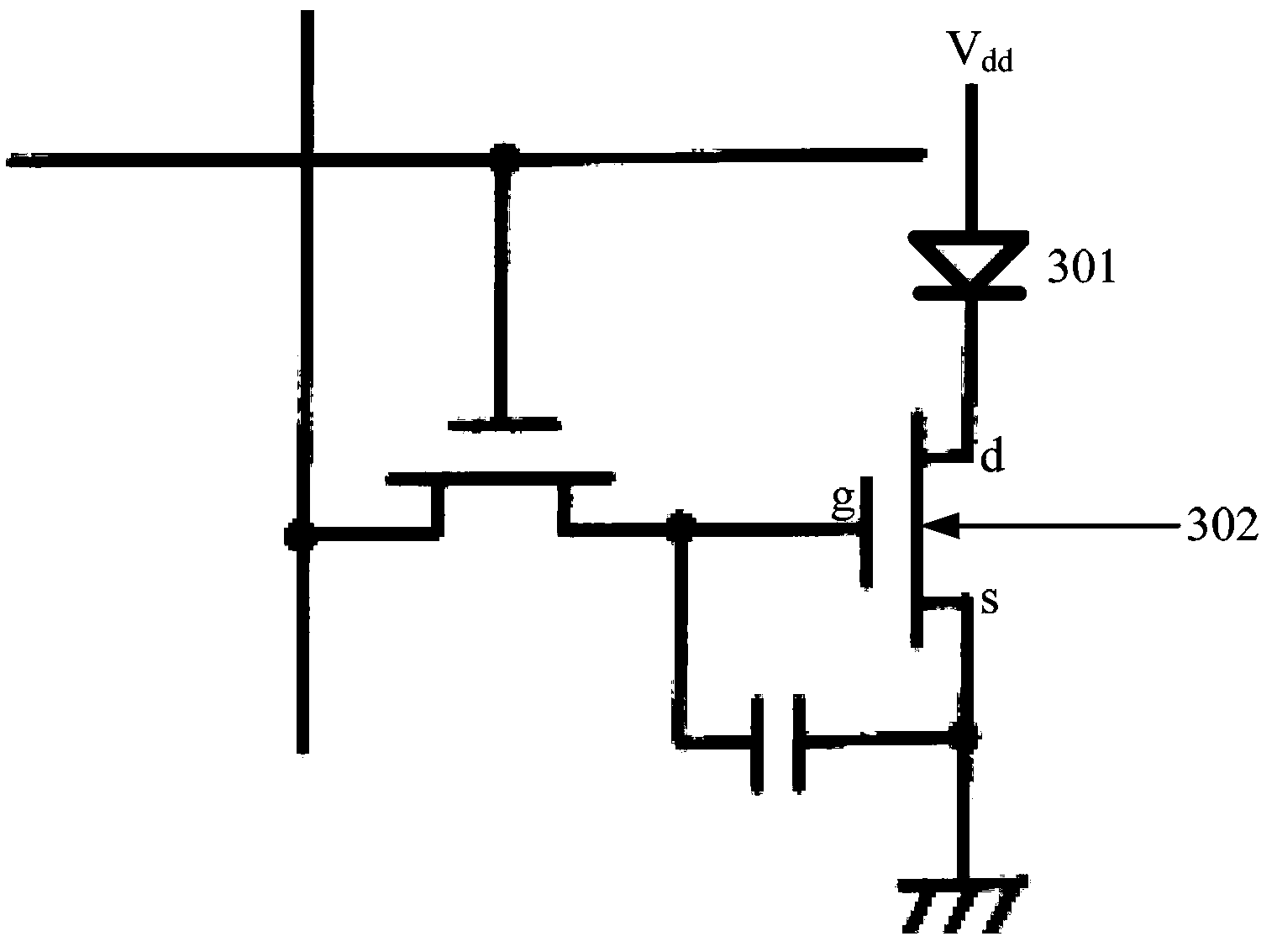

[0085] Based on Embodiment 1, this embodiment provides an active matrix organic light-emitting diode panel, which is produced by the manufacturing method provided in Embodiment 1. The device includes:

[0086] A thin film field effect transistor array substrate, the thin film field effect transistor array substrate comprising a substrate and a plurality of thin film field effect transistors arranged on the surface of the substrate;

[0087] a cathode located on the surface of the thin film field effect transistor array substrate, the cathode is connected to the drain of the thin film field effect transistor;

[0088] An electron injection layer located on the surface of the cathode, the electron injection layer comprising a first electron injection layer located on the surface of the cathode and adjacent to the cathode and a second electron injection layer located on the surface of the first electron injection layer , the first electron injection layer is an aluminum layer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com