Multi-principal-component high-temperature alloy and preparation method thereof

A superalloy and multi-principal technology, applied in the field of multi-principal superalloy and its preparation, can solve the problems of difficulty in guaranteeing the size and shape of the formed parts, high production cost and difficulty, poor plastic rheology, etc., and achieve the maximum improvement. Compressive strength, optimized mechanical properties, and the effect of room temperature plasticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

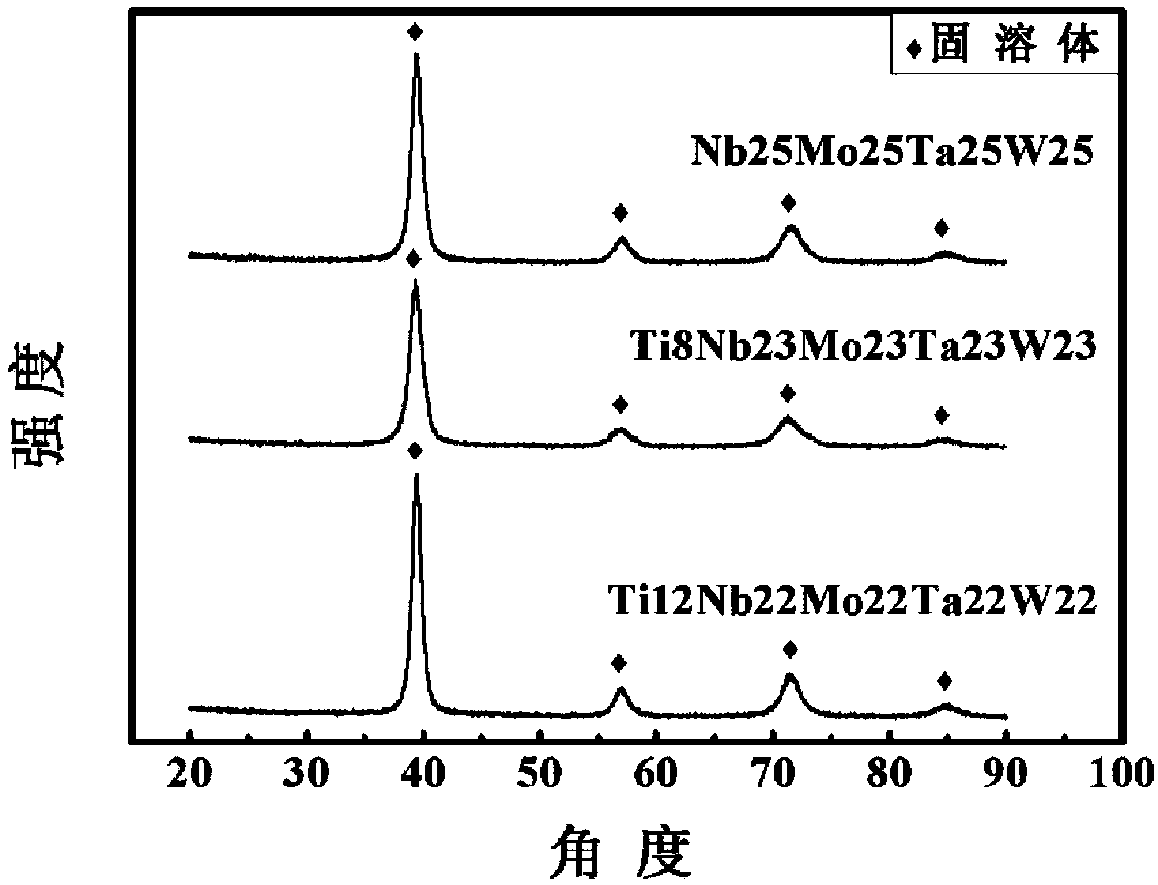

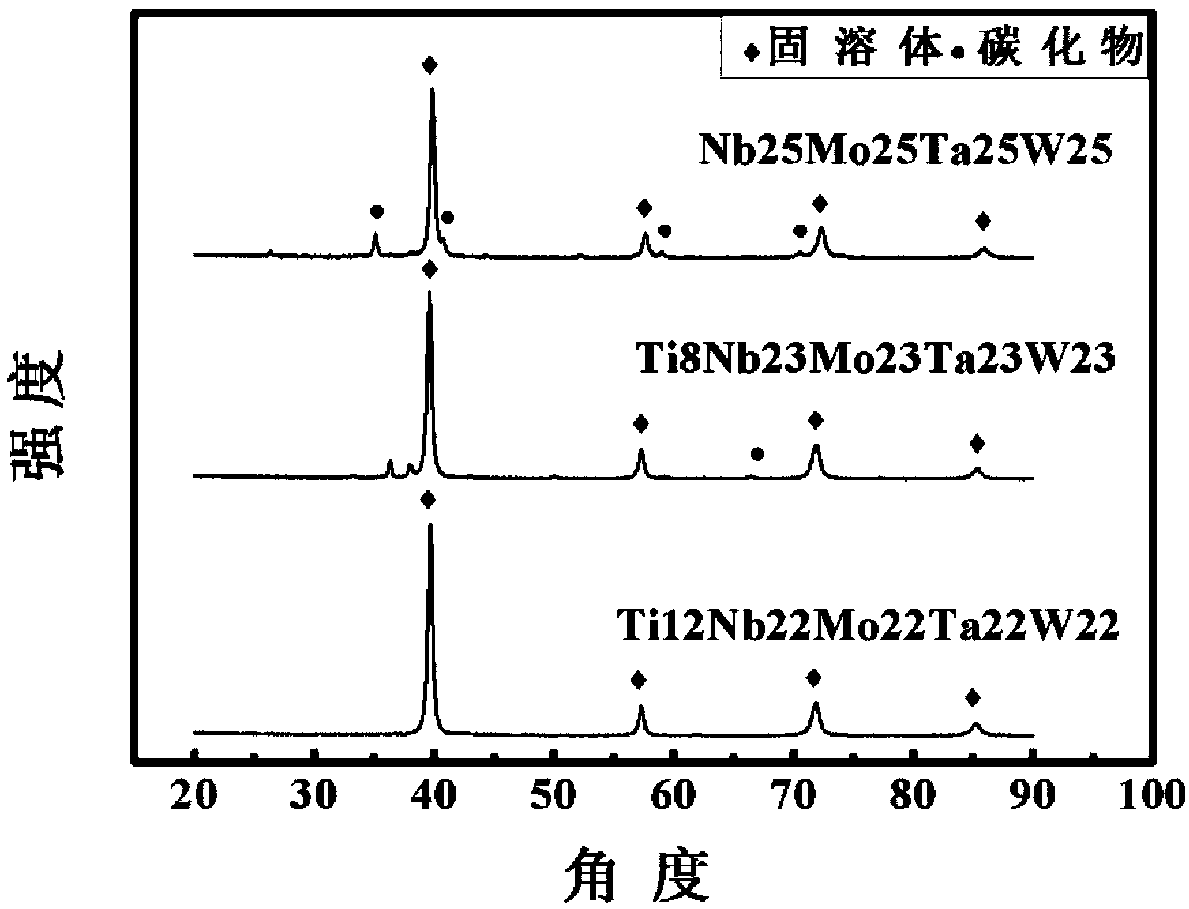

[0031] A multi-principal superalloy, the multi-principal superalloy adds element Ti on the basis of Nb, Mo, Ta, W four elements, and its molecular formula is Ti 8 Nb 23 Mo 23 Ta23 W 23 .

[0032] A method for preparing a multi-principal superalloy, the method adopts the technology of combining mechanical alloying and spark plasma sintering, and the steps are as follows:

[0033] 1) Preparation of alloy powder by mechanical alloying method: according to the atomic percentage of elements 23%, 23%, 23%, 23% and 8%, five elemental powders of Nb, Mo, Ta, W, and Ti are mixed uniformly to obtain a mixed powder, wherein The particle size of each powder is 2-48 μm, and the purity is 99.5-99.95wt%;

[0034] 2) Add the mixed powder and balls into the ball mill tank of planetary high-energy ball mill for ball milling. The material of the tank body and the balls are made of hard alloy. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as Protective atmosphere....

Embodiment 2

[0044] A multi-principal superalloy, the multi-principal superalloy adds element Ti on the basis of Nb, Mo, Ta, W four elements, and its molecular formula is Ti 12 Nb 22 Mo 22 Ta 22 W 22 .

[0045] A method for preparing a multi-principal superalloy, the method adopts the technology of combining mechanical alloying and spark plasma sintering, and the steps are as follows:

[0046] 1) Preparation of alloy powder by mechanical alloying method: according to the atomic percentage of elements 22%, 22%, 22%, 22% and 12%, five elemental powders of Nb, Mo, Ta, W, and Ti were uniformly mixed to obtain a mixed powder, wherein The particle size of each powder is 2-48μm, and the purity is 99.5-99.95%;

[0047] 2) Add the mixed powder and balls into the ball mill tank of planetary high-energy ball mill for ball milling. The material of the tank body and the balls are made of hard alloy. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as Protective atmospher...

Embodiment 3

[0057] A multi-principal superalloy, the multi-principal superalloy adds element Ti on the basis of Nb, Mo, Ta, W four elements, and its molecular formula is Ti 8 Nb 23 Mo 23 Ta 23 W 23 .

[0058] A method for preparing a multi-principal superalloy, the method adopts the technology of combining mechanical alloying and spark plasma sintering, and the steps are as follows:

[0059] 1) Preparation of alloy powder by mechanical alloying method: according to the atomic percentage of elements 23%, 23%, 23%, 23% and 8%, five elemental powders of Nb, Mo, Ta, W, and Ti are mixed uniformly to obtain a mixed powder, wherein The particle size of each powder is 2-48μm, and the purity is 99.5-99.95%;

[0060] 2) Add the mixed powder and balls into the ball mill tank of planetary high-energy ball mill for ball milling. The material of the tank body and the balls are made of hard alloy. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as Protective atmosphere. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com