All-plastic building formwork

A technology of building formwork and backing plate, which is applied in construction, building structure, formwork/formwork components, etc., can solve the problems of difficult to achieve anti-drop and not easy to deform, difficult to align installation, hidden safety hazards, etc., to achieve excellent anti-drop and economical cost, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

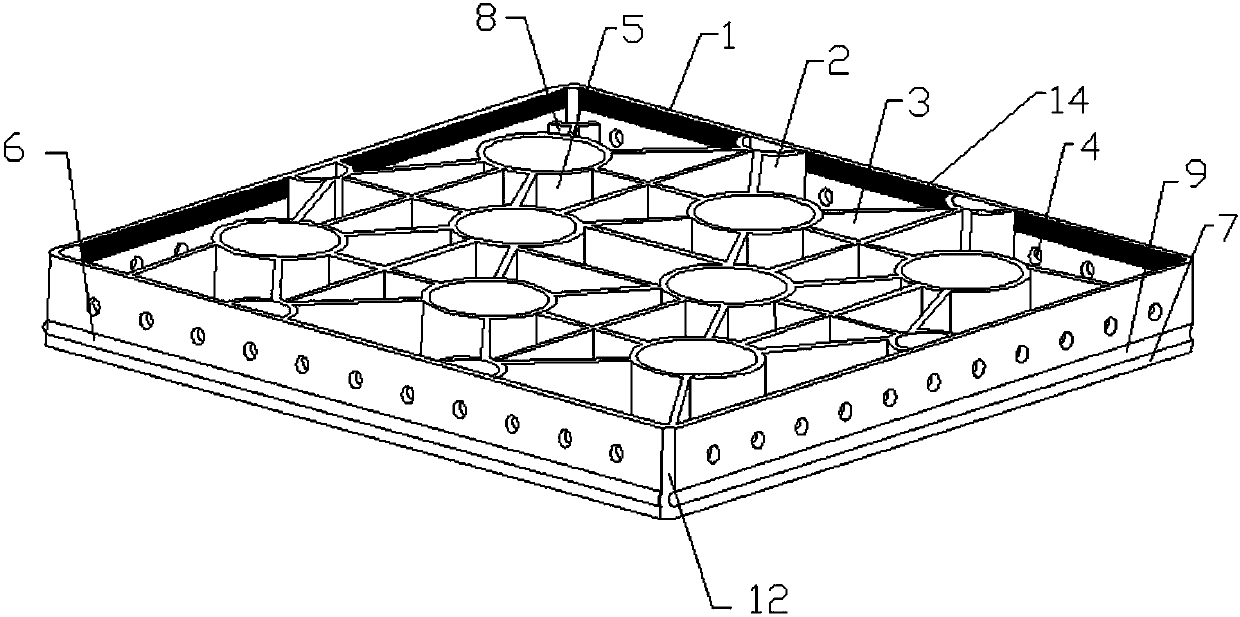

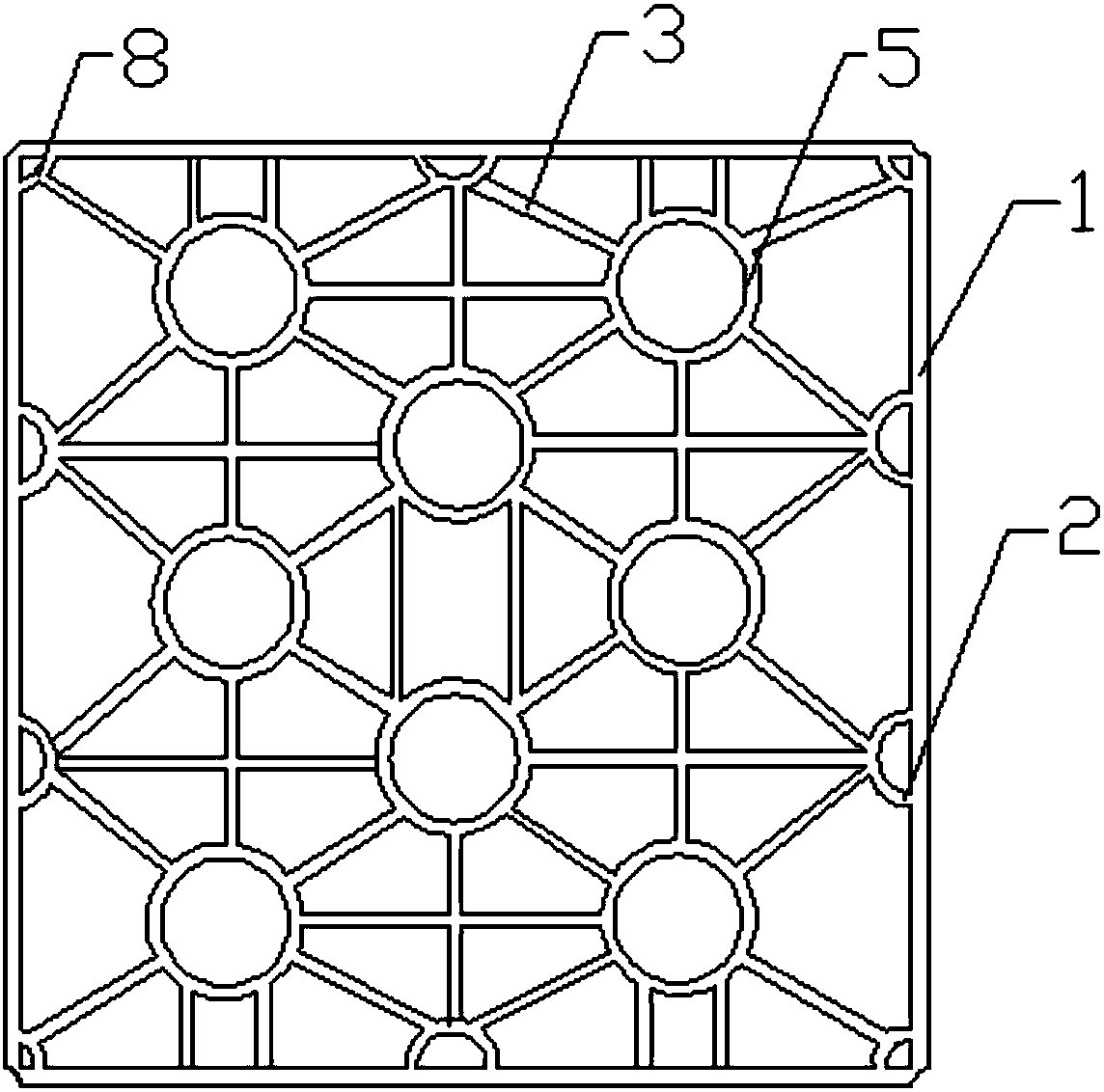

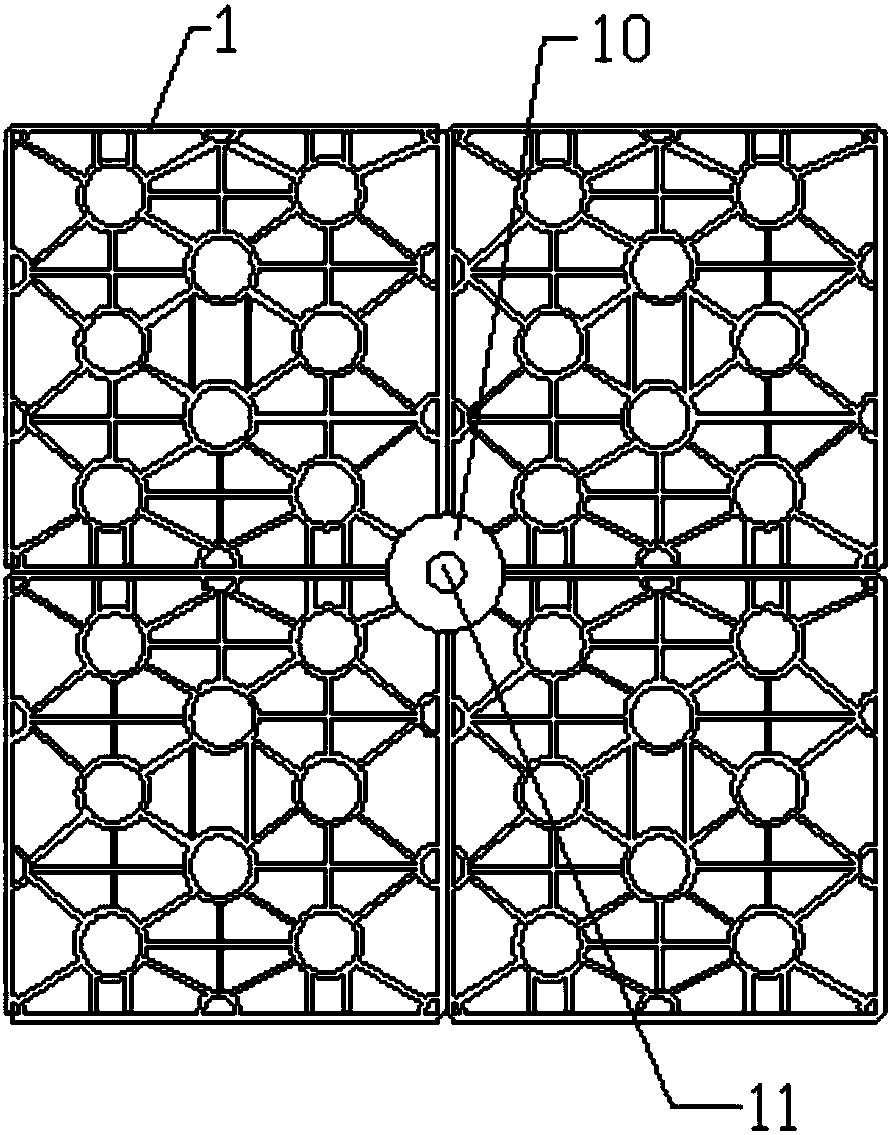

[0017] Example: such as Figure 1-2 As shown, the present invention provides an all-plastic building formwork, comprising a surrounding board 1, the surrounding board 1 is a square, and the four corners of the surrounding board 1 are concave structures, and the edges of the surrounding board are provided with chamfers 14, which is convenient For installation, one side of the surrounding board 1 is provided with a semi-arc support plate 2, and the number of the semi-arc support plates 2 is six, which are respectively arranged on the edge of the surrounding board 1, wherein four sides of the surrounding board 1 are provided with Half-arc support plates 2, each half-arc support plates 2 are of the same size, and are symmetrically arranged in pairs, and two semi-arc support plates 2 are arranged on the other two sides, and the two are symmetrically arranged, and the semi-arc support plates 2 One side is provided with a support strip 3, the height of the support strip 3 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com