Supporting method of side template at later casting zone of floor part

A technology of post-casting strips and lateral formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., and can solve the problems of heavy workload of on-site workers, large amount of chiseling in the later stage, and large waste of formwork and other problems, to achieve the effects of simple and fast support and demolition construction, less cutting and chiseling in the later stage, and better appearance of concrete sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

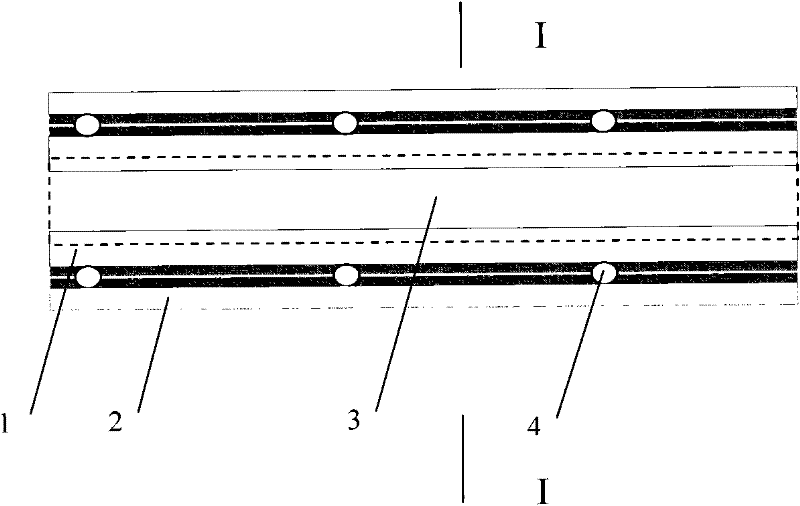

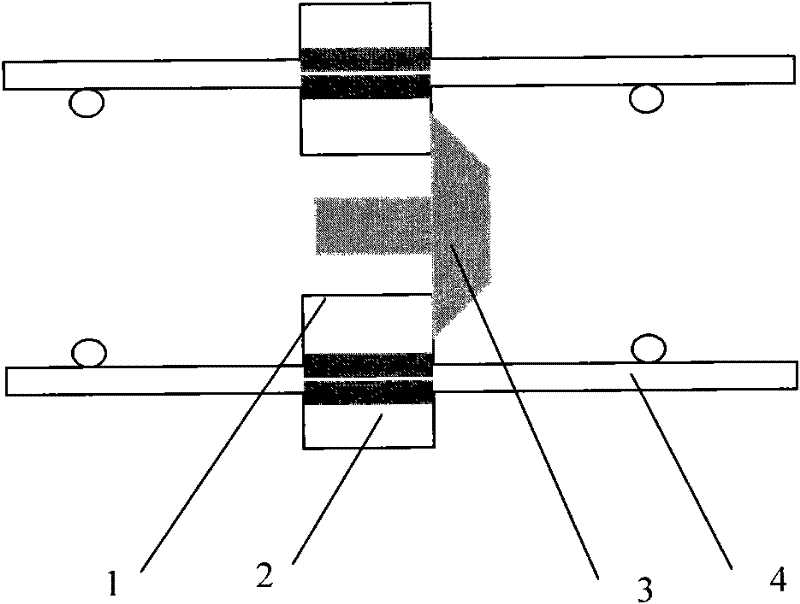

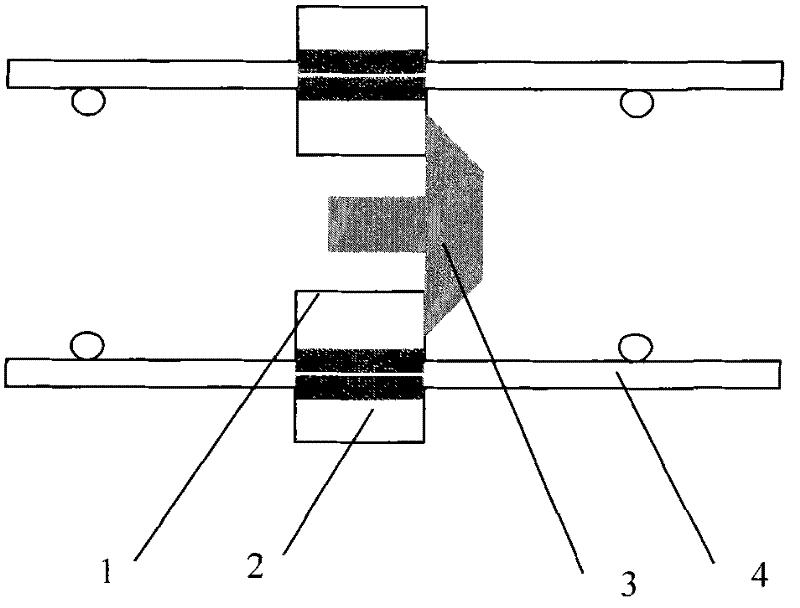

[0012] Such as figure 1 As shown, the lower composite strip 2 is placed on the lower part of the floor reinforcement 4 in the lower row, and the flexible material layer of the lower composite strip 2 is attached to one side of the floor reinforcement 4, and the upper composite strip 1 is placed on the top of the floor reinforcement 4, and the flexible material layer of the upper composite strip 1 Paste on the side of the floor steel bar 4, clamp and fix the hard material layer of the upper composite strip 1 and the lower composite strip 2, so that the lower row of floor steel bars 4 is wrapped by the upper composite strip 1 and the lower composite strip 2 , the upper composite strip 1 flexible material layer and the lower composite strip 2 flexible material layer are also tightly fitted without gaps, and the row of steel bars on the floor is also clamped and fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com