Hollow box device for ultra-thick hollow floor and manufacturing method thereof

A hollow floor and box technology, which is applied to floors, building components, buildings, etc., can solve the problems of hollow box structure, aluminum alloy hollow box perforation, and hollow floor, etc., and achieves strong anti-deformation ability , production flexibility, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

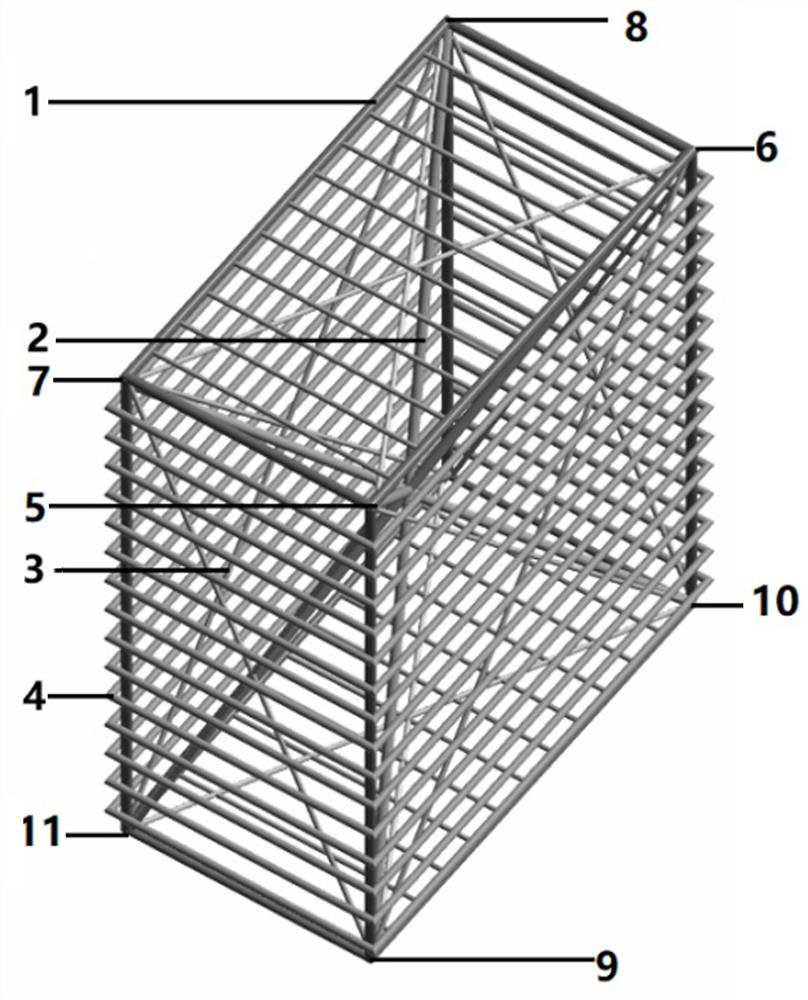

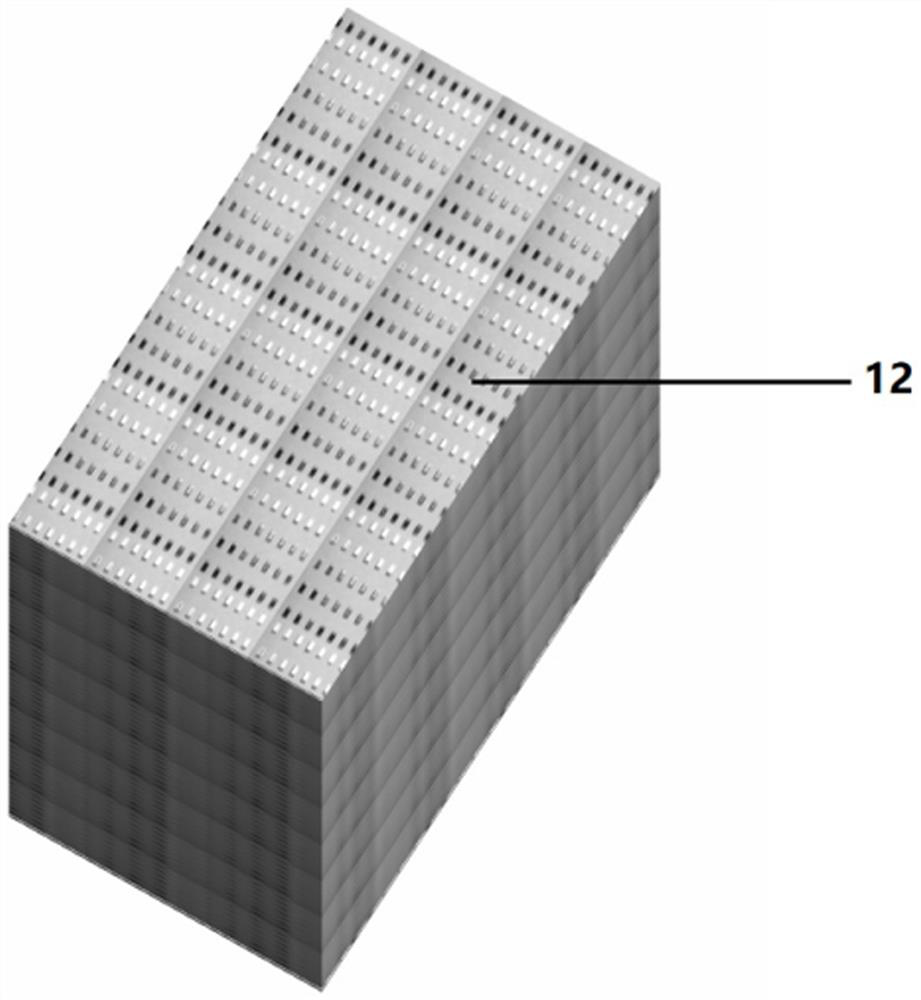

[0026] Such as figure 1 and figure 2 As shown, a hollow box device for an ultra-thick hollow floor slab includes a skeleton shaped as a cuboid, a shut-off plate 12 for sealing the outer surface of the skeleton, and the shut-off plate 12 is welded and fixed to the outer surface of the skeleton. The board 12 seals the skeleton to prevent the mortar from leaking into the skeleton and increase the weight of the hollow floor slab. The first rib mechanism used to connect two vertices, the second rib mechanism located on the side of the skeleton and used to connect two adjacent ribs 1, the ribs 1 are twelve, and two adjacent ribs The end of the rib 1 is welded and fixed, and there are eight vertices, and the eight vertices successively include the first vertices 5, the second vertices 6 on the right side of the first vertices, and the second vertices behind the first vertices 5. The third corner 7 on the side, the fourth corner 8 on the right side of the third corner 7, the fifth ...

Embodiment 2

[0032] Such as figure 1 and figure 2 As shown, a hollow box device for an ultra-thick hollow floor slab includes a skeleton shaped as a cuboid, a shut-off plate 12 for sealing the outer surface of the skeleton, and the shut-off plate 12 is welded and fixed to the outer surface of the skeleton. The board 12 seals the skeleton to prevent the mortar from leaking into the skeleton and increase the weight of the hollow floor slab. The first rib mechanism used to connect two vertices, the second rib mechanism located on the side of the skeleton and used to connect two adjacent ribs 1, the ribs 1 are twelve, and two adjacent ribs The end of the rib 1 is welded and fixed, and there are eight vertices, and the eight vertices successively include the first vertices 5, the second vertices 6 on the right side of the first vertices, and the second vertices behind the first vertices 5. The third corner 7 on the side, the fourth corner 8 on the right side of the third corner 7, the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com