A construction formwork for gypsum cast-in-place wall and its construction method

A cast-in-place wall and formwork technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of easy slurry leakage and low efficiency, and achieve difficult slurry leakage and high efficiency. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

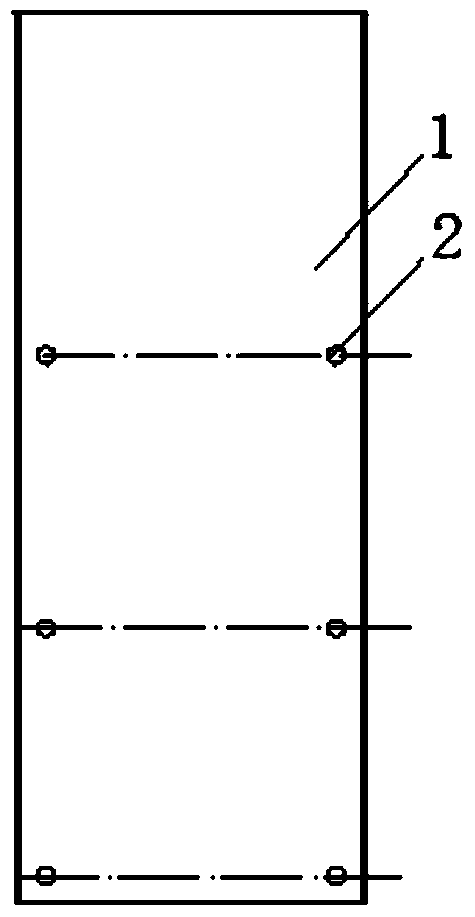

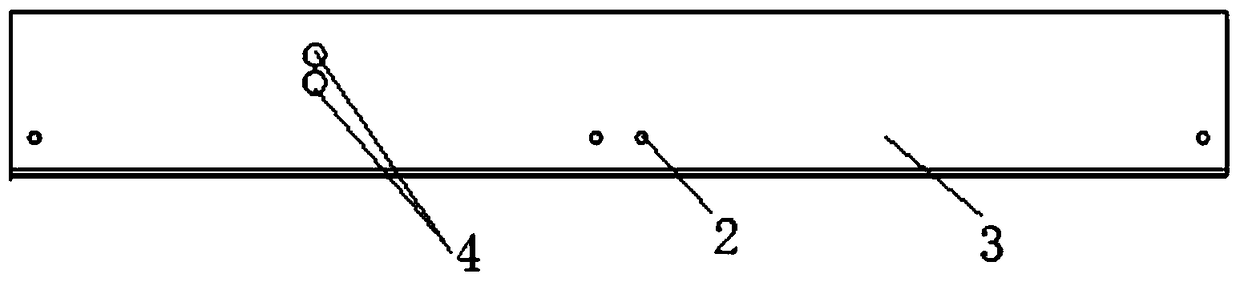

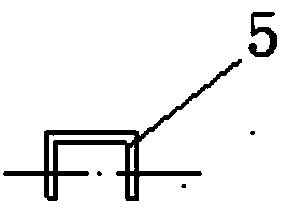

[0032] A construction formwork for a gypsum cast-in-place wall, comprising a main formwork 1 for pouring gypsum-based wall materials, a side formwork 5 for closing the main formwork 1 during pouring, a bottom formwork 3 for pouring waterproof cushion materials, The clamping mold 6 and the bolt 9 of the main surface formwork 1 of the limit during pouring and the inner limit sleeve 10 that is set on the bolt 9 and acts as a limit during pouring, the height of the bottom formwork 3 is adapted to the height of the waterproof cushion (the height of the bottom formwork 3 is slightly higher than the height of the waterproof cushion), the height of the main formwork 1 and the side formwork 5 is adapted to the height of the wall (the height of the main formwork 1 and the side formwork 5 is slightly lower than the height of the wall body height, in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com