Upright post formwork

A column and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of complex fixing, deformation of the bottom end, high quality of steel formwork, etc., and achieve the purpose of increasing the connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

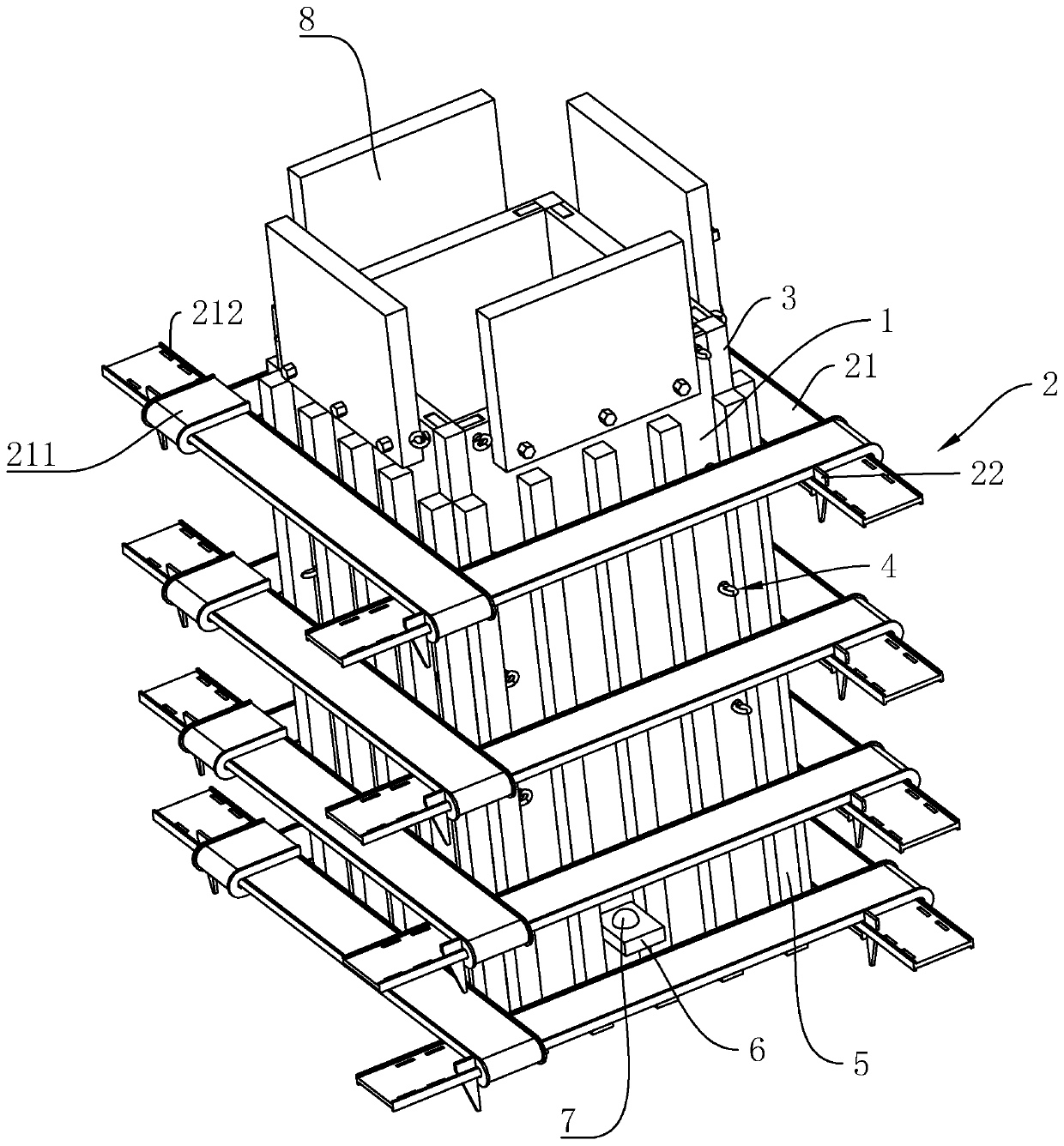

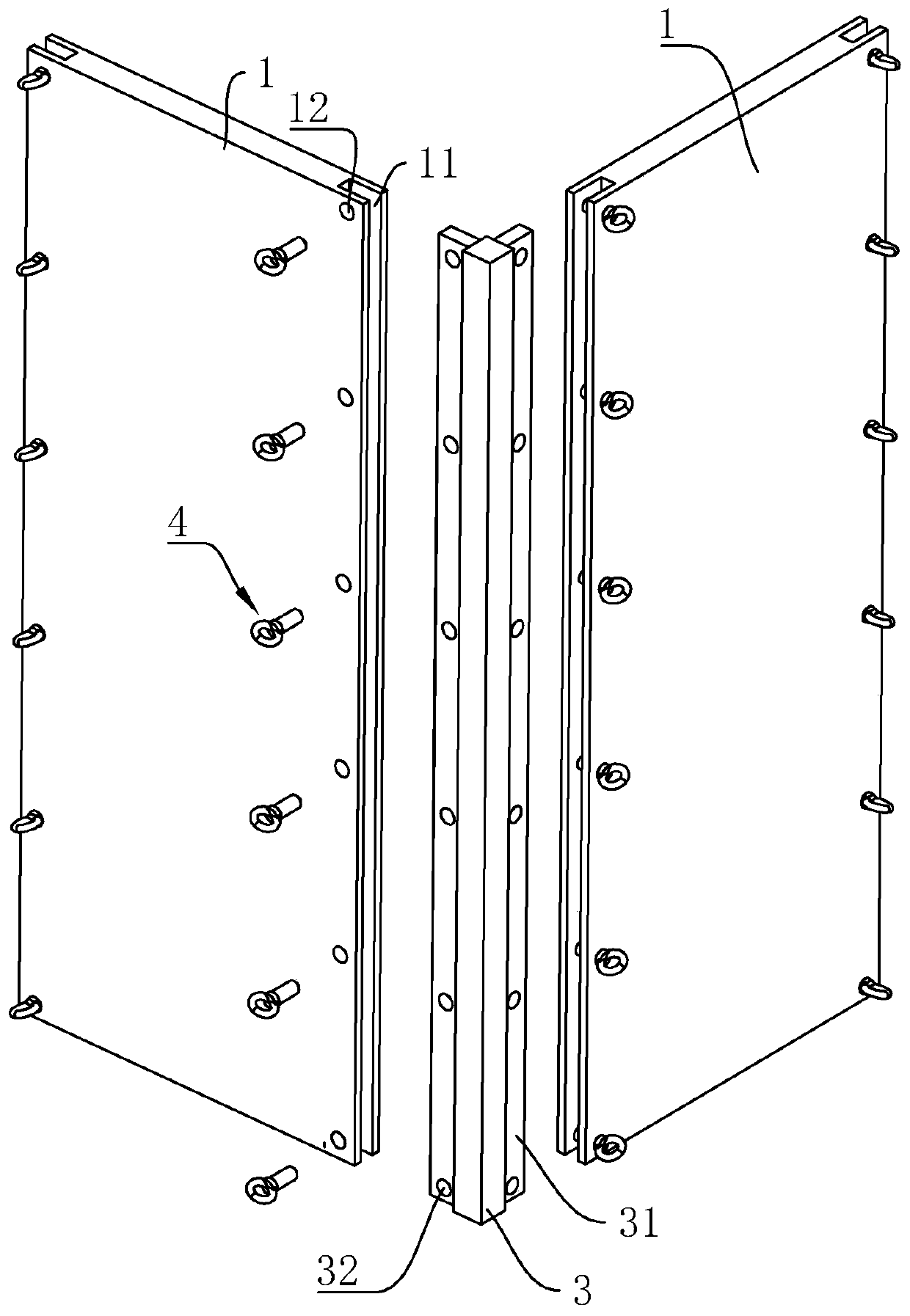

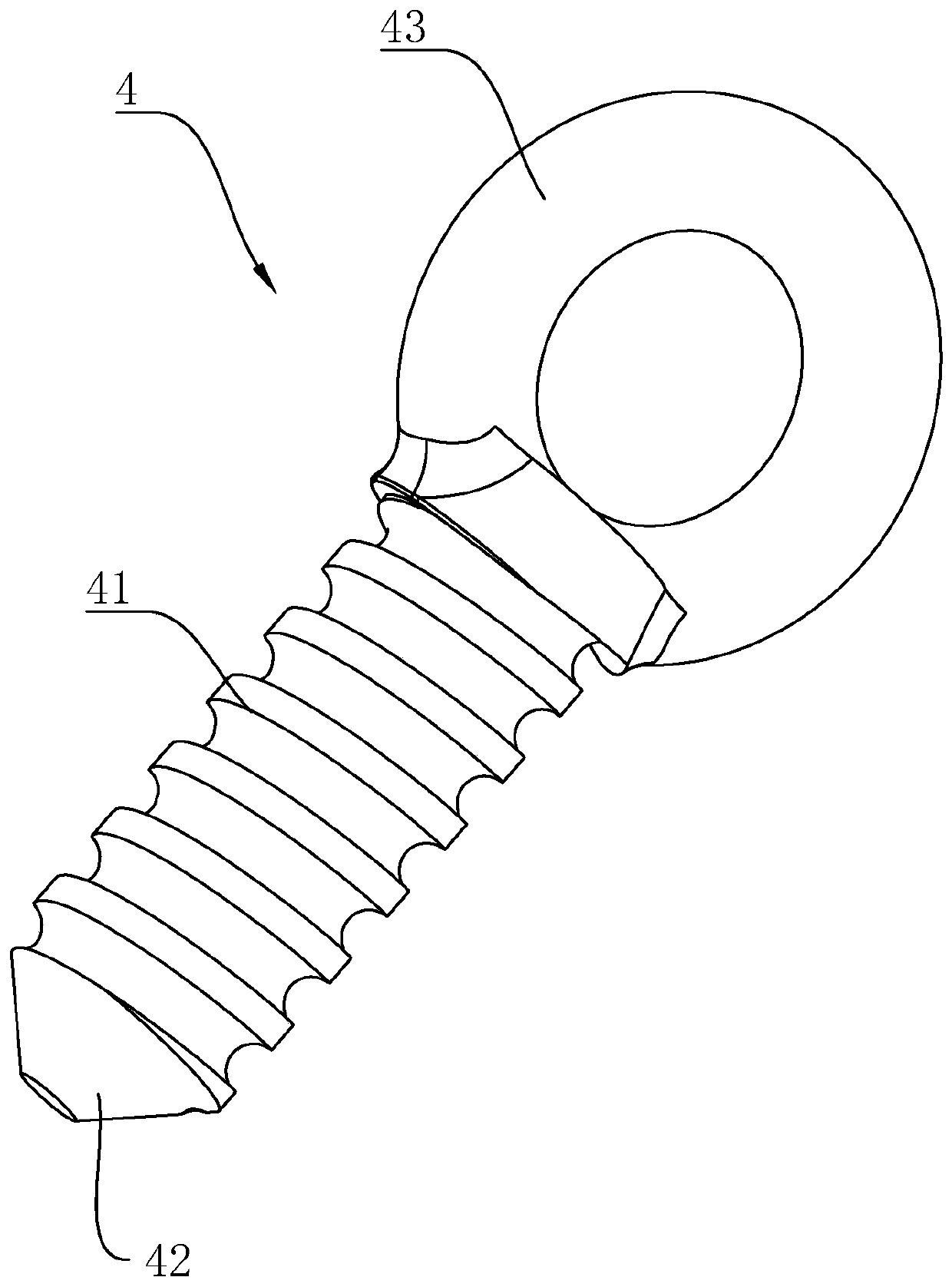

[0037] refer to figure 1 , is a column formwork disclosed in the present invention, comprising four steel formworks 1, and the four steel formworks 1 enclose a rectangular hollow columnar structure. Several fasteners 2 hooped on the four steel templates 1 are arranged outside the four steel templates 1 , and the fasteners 2 are arranged along the height direction of the steel templates 1 . The distance between adjacent fasteners 2 decreases gradually from the top end of the steel formwork 1 to the bottom end of the steel formwork 1 . The left and right sides of the adjacent steel formworks 1 abut against one side close to the inside of the enclosed columnar structure, so that the joints of the adjacent steel formworks 1 are positioned to form an installation notch.

[0038] refer to figure 1 , figure 2 A connecting column 3 with a square cross-section is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com