Construction method for pouring airtight partition wall between recovered roadway and reserved roadway

A construction method and partition wall technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of slow construction speed, uneconomical, and poor airtightness of the roof, and achieve fast construction speed, high labor efficiency, and less grout leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

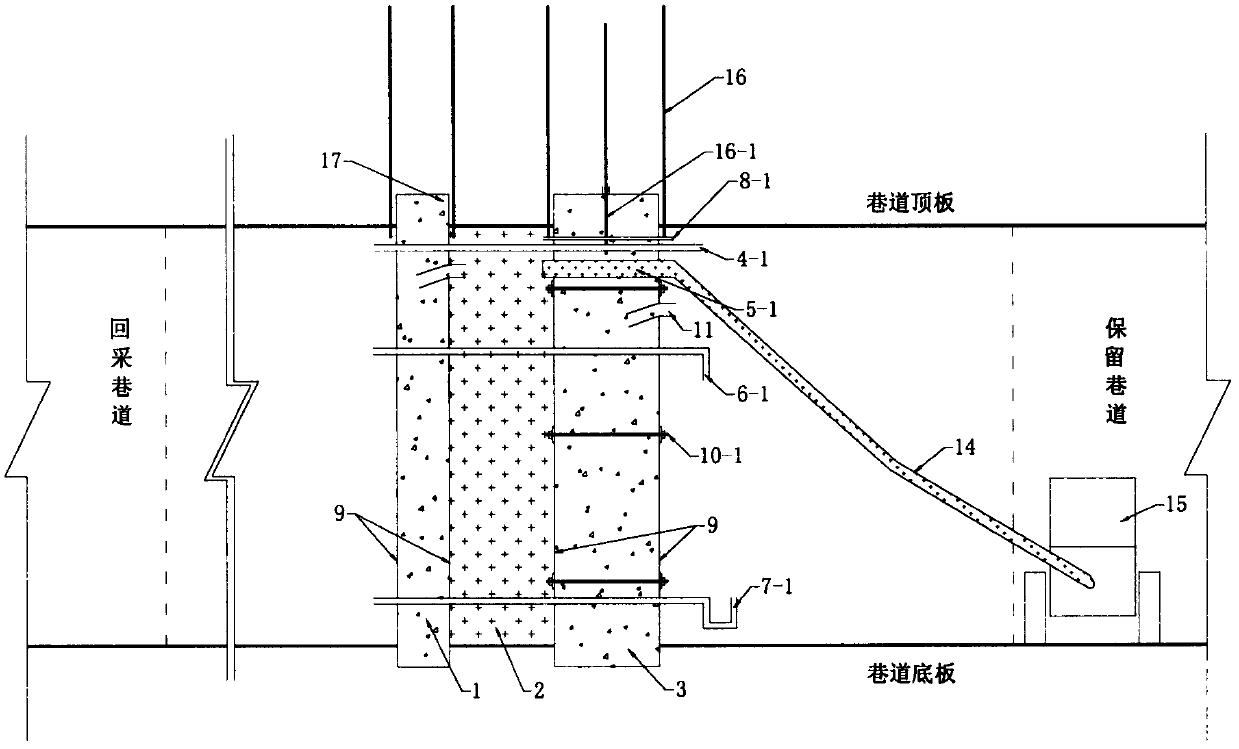

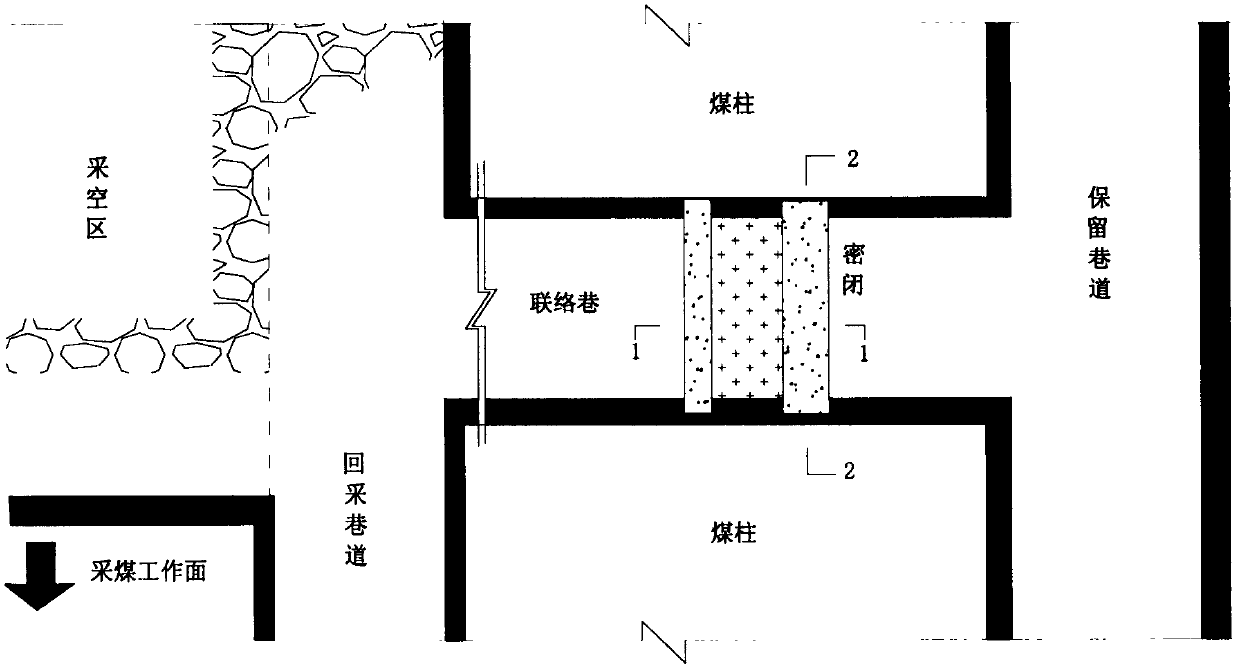

[0038] refer to Figure 1-10 A kind of construction method of pouring airtight partition wall between mining and reserved roadway, carry out according to the following steps:

[0039] 1), the airtight partition wall is composed of concrete inner single wall 1, concrete outer single wall 3, and loess concrete middle wall 2;

[0040] 2), according to the size and function of the airtight partition wall, the flexible formwork 9 is prefabricated;

[0041] 3), excavate a cut 17 in the surrounding rock of the concrete inner single wall 1 and the outer single wall 3 to be set;

[0042] 4), drill bolt holes at the surrounding rock cutouts around the inner and outer concrete single walls, and install bolts 16 in the bolt holes;

[0043] 5), hang the prefabricated flexible formwork 9 on the anchor rod 16 or the single hydraulic prop 18, and inject concrete into the flexible formwork 9 through the concrete pump 15 through the concrete delivery pipe 14 and the pouring port 11 to form th...

Embodiment 2

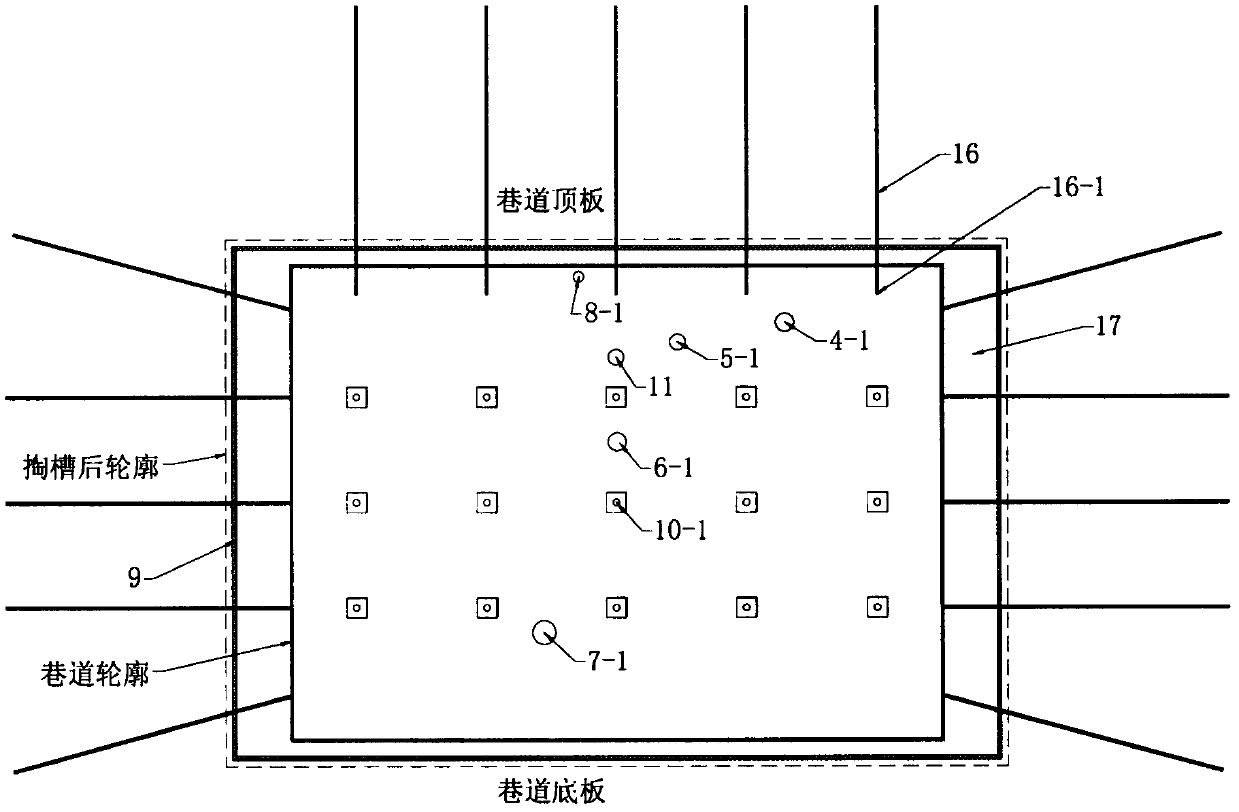

[0056] refer to Figure 5 , 2, 3, 7, 8, 9, 10: this airtight partition wall is made up of brick wall 1-1, concrete outer single wall 3 and middle loess concrete middle wall 2. The concrete outer single wall 3 has a groove 17 at the periphery of the roadway at the closed wall, and an anchor rod 16 is built in the groove, and the exposed end 16-1 of the anchor rod is inserted into the reinforcement opening 13, and the reinforcement opening 13 is bound by iron wire, and the anchor rod 16 The exposed end is bonded to the concrete in the flexible formwork 9, and the flexible formwork 9 is provided with flanges 12, anchor bolt holes 10, pouring ports 11, as well as measure pipe holes 4, observation pipe holes 6, and backwater pipe holes 7, etc. Holes, anchor bolt holes 10, measure pipe holes 4, observation pipe holes 6, and reverse water pipe holes 7 are respectively embedded with anchor bolts 10-1, measure pipes 4-1, observation pipes 6-1, and reverse water pipes 7-1. Between the...

Embodiment 3

[0059] refer to Image 6 , 2 , 3, 7, 8, 9, and 10 show: a groove 17 is drawn around the roadway at the airtight partition wall, and an anchor rod 16 is built in the groove, and the exposed end 16-1 of the anchor rod penetrates the planting reinforcement port 13, and the planting reinforcement port 13 passes through Iron wire binding, the exposed end of the anchor rod 16 is bonded to the concrete in the flexible formwork 9, and the flexible formwork 9 is provided with a flange 12, an anchor bolt hole 10, a pouring port 11, and a measure pipe hole 4, an observation pipe hole 6, and a backwater pipe hole 7 and other closed holes are reserved, the anchor bolt hole 10, the measure pipe hole 4, the observation pipe hole 6, and the reverse water pipe hole 7 are respectively pre-buried anchor bolt 10-1, measure pipe 4-1, observation pipe 6-1, reverse water pipe hole 7, etc. Water pipe 7-1, such that the concrete airtight outer single wall 3 forms a concrete airtight partition wall. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com