Construction method of PCF board for fabricated building

A construction method and technology used in construction, applied in the direction of construction, building components, building structures, etc., can solve problems such as collisions, achieve the effects of improving safety, avoiding uncompacted concrete, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

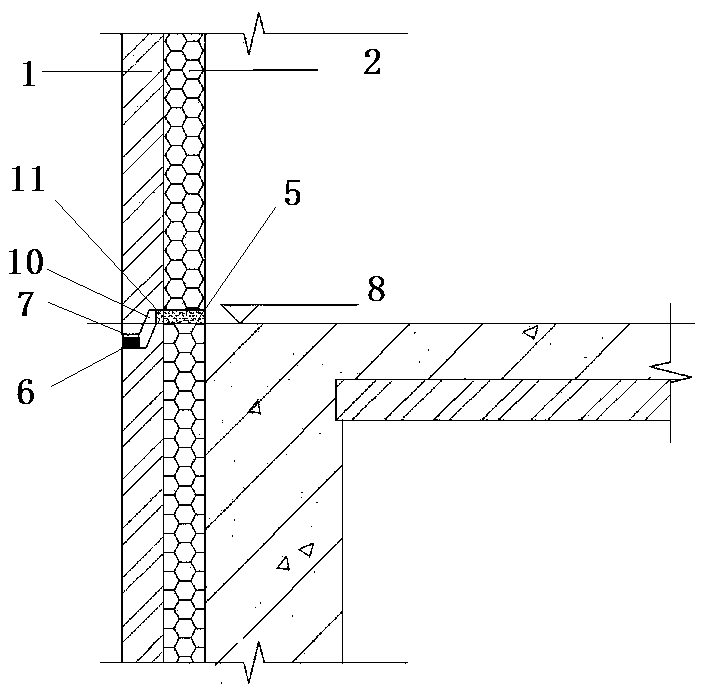

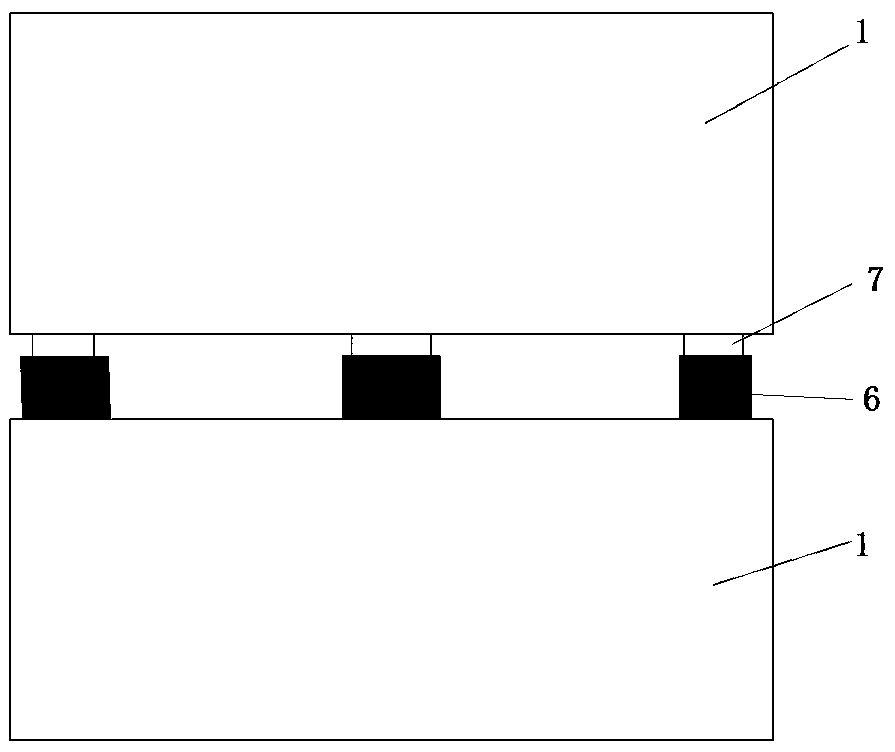

[0037] The present invention will be further described below in conjunction with accompanying drawing.

[0038] A kind of PCF plate construction method for prefabricated building, comprises the following steps:

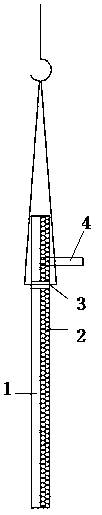

[0039] 1) In the production of PCF boards, φ80 through holes are reserved for PCF boards during production as hoisting holes during hoisting. For the reserved holes of the outer frame and wall parts, after the construction is completed, fill the insulation boards in the hoisting holes, seal them with waterproof mortar, and brush the outside with waterproof paint to ensure sealing;

[0040] 2) Base level cleaning, setting out, and adjusting the elevation. Clean up the PCF board and the root of the wall to be hoisted in advance.

[0041] Lay out the lines, release the edge lines at both ends of the PCF outer slab and the edge lines and control lines of the cast-in-place part of the wall, and use the black ink line to bounce on the structural floor. It is necessary to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com