Device and method for casting concrete continuous walls along gob-side entry retaining by mining working face

A technology for pouring concrete and retaining roadways, which is applied in mining equipment, shaft equipment, earthwork drilling and mining, etc. It can solve problems such as tight connection of roofs in difficult coal seams, difficulty in rigid formwork, and concrete that is prone to leakage of grout, and achieves good roofing effect, Not easy to leak slurry, good airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, content of the invention is further described:

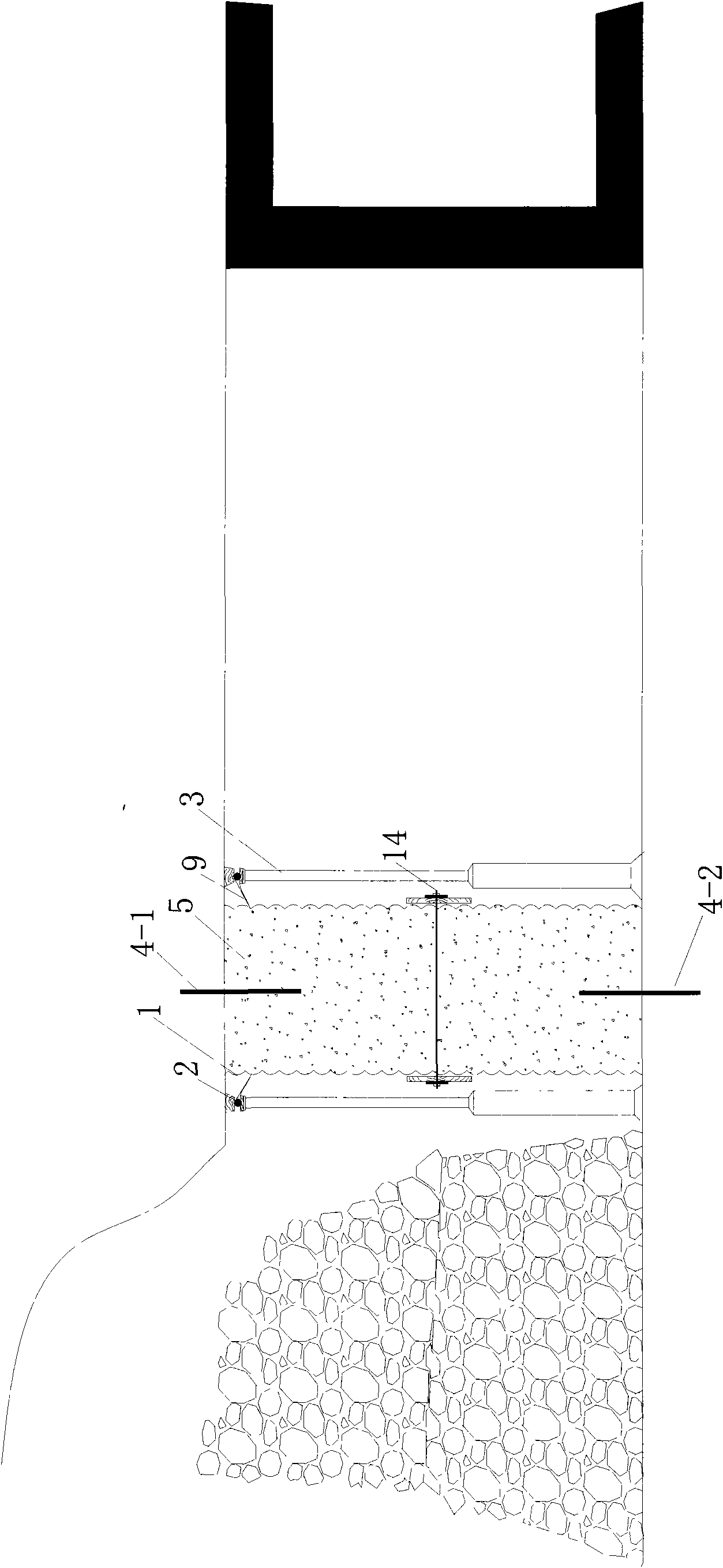

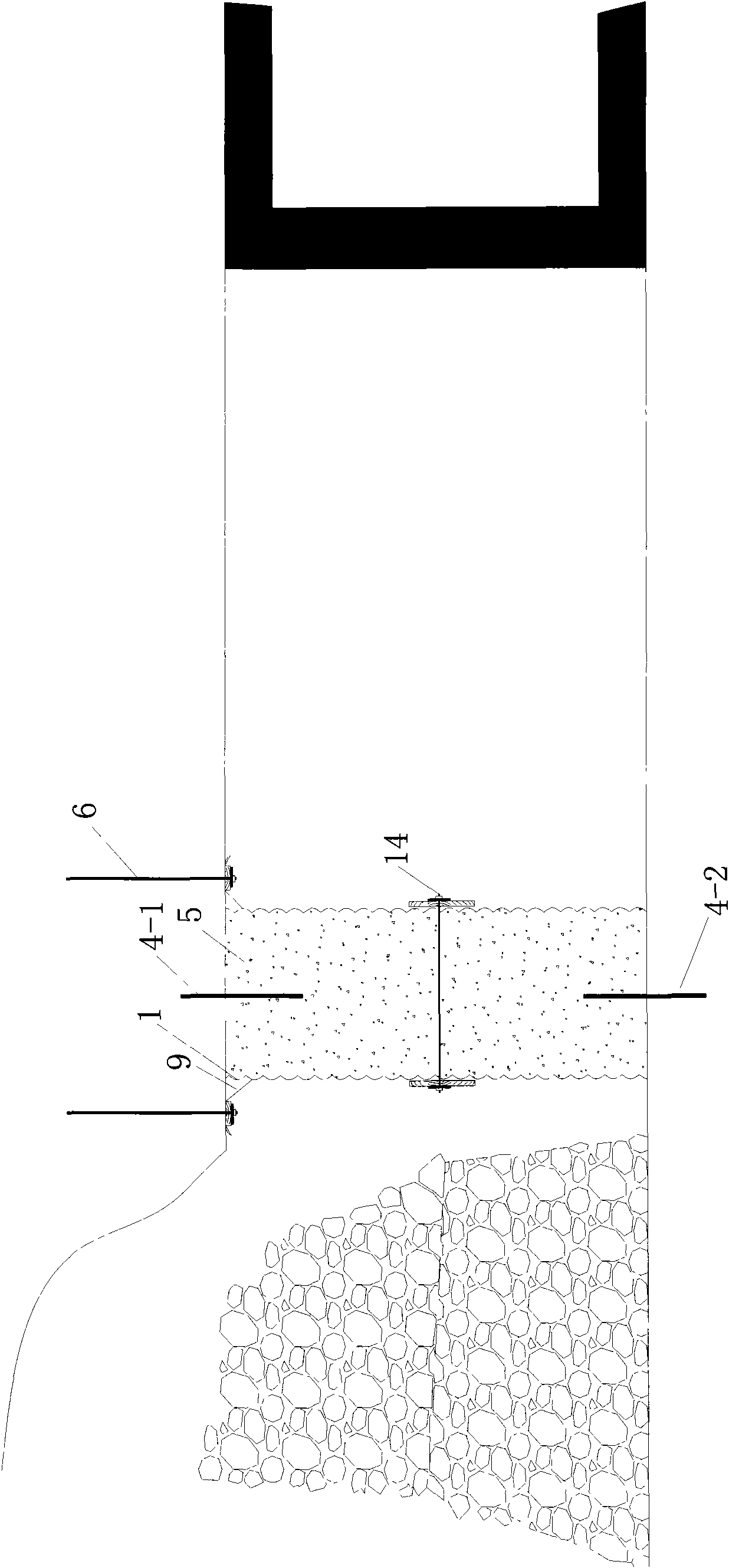

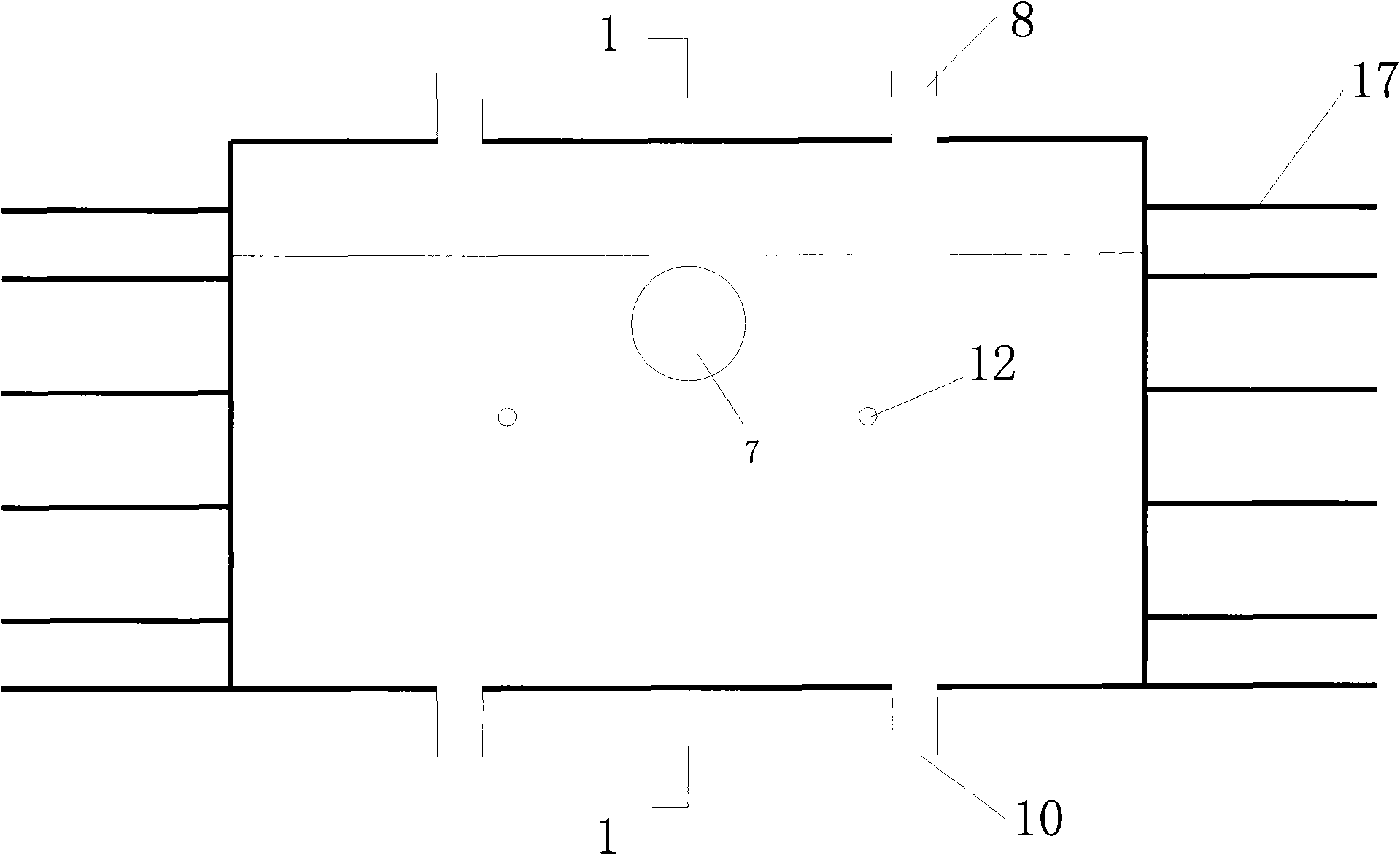

[0023] refer to Figure 1-Figure 4 As shown: a fiber flexible formwork 1 is composed of a main formwork 15 and a top formwork 16. The two sides of the fiber flexible formwork are respectively connected to the flange 9, and the flange 9 is equipped with a sleeve 11, and the sleeve 11 is penetrated with a The steel beam 2 and the flange 9 hang the fiber flexible formwork 1 on the coal seam roof through the single hydraulic prop 3 or the anchor rod 6, and the fiber flexible formwork 1 is respectively connected to the pouring port 7, the upper reinforcement opening 8, and the lower reinforcement reinforcement in turn. Port 10, limit hole 12, one end of the upper planting bar 4-1 is connected to the coal seam roof, the other end is inserted into the fiber flexible formwork 1 through the upper planting bar port 8 and fixedly connected with the concrete 5, and one end of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com