Patents

Literature

36results about How to "To achieve the purpose of filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

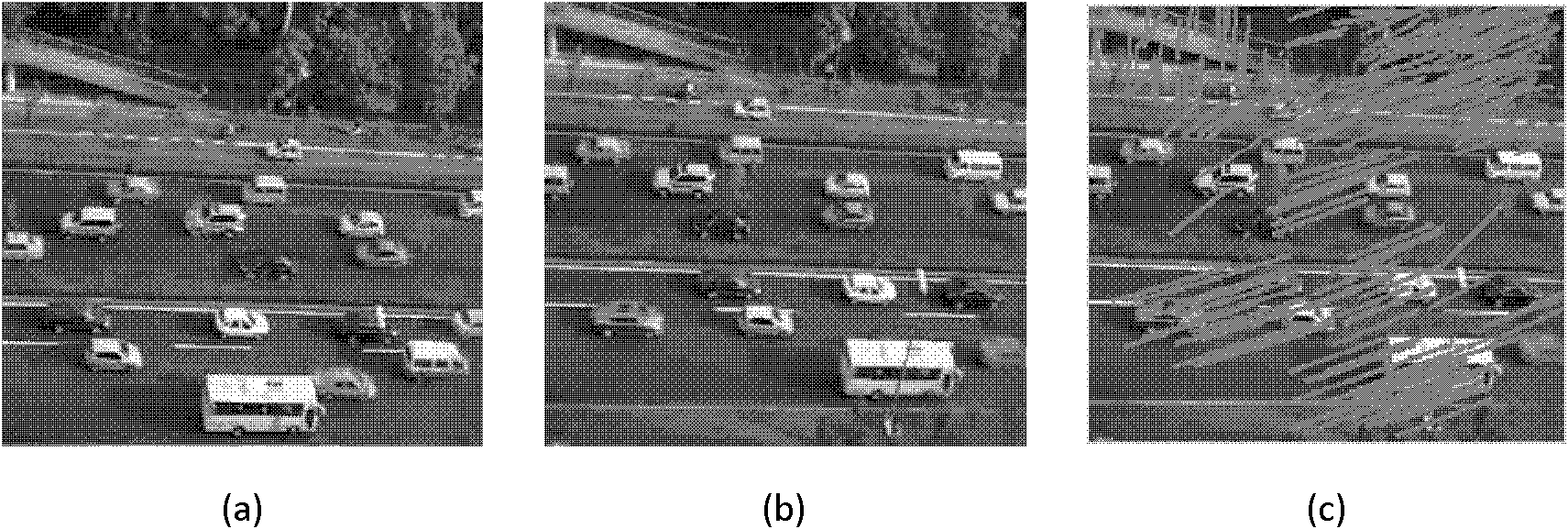

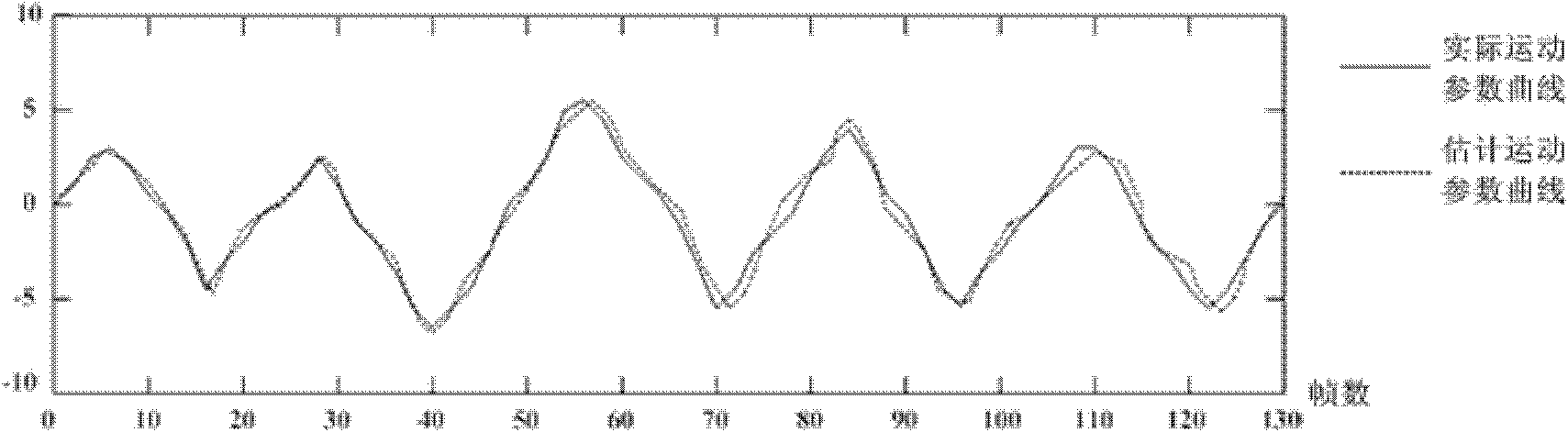

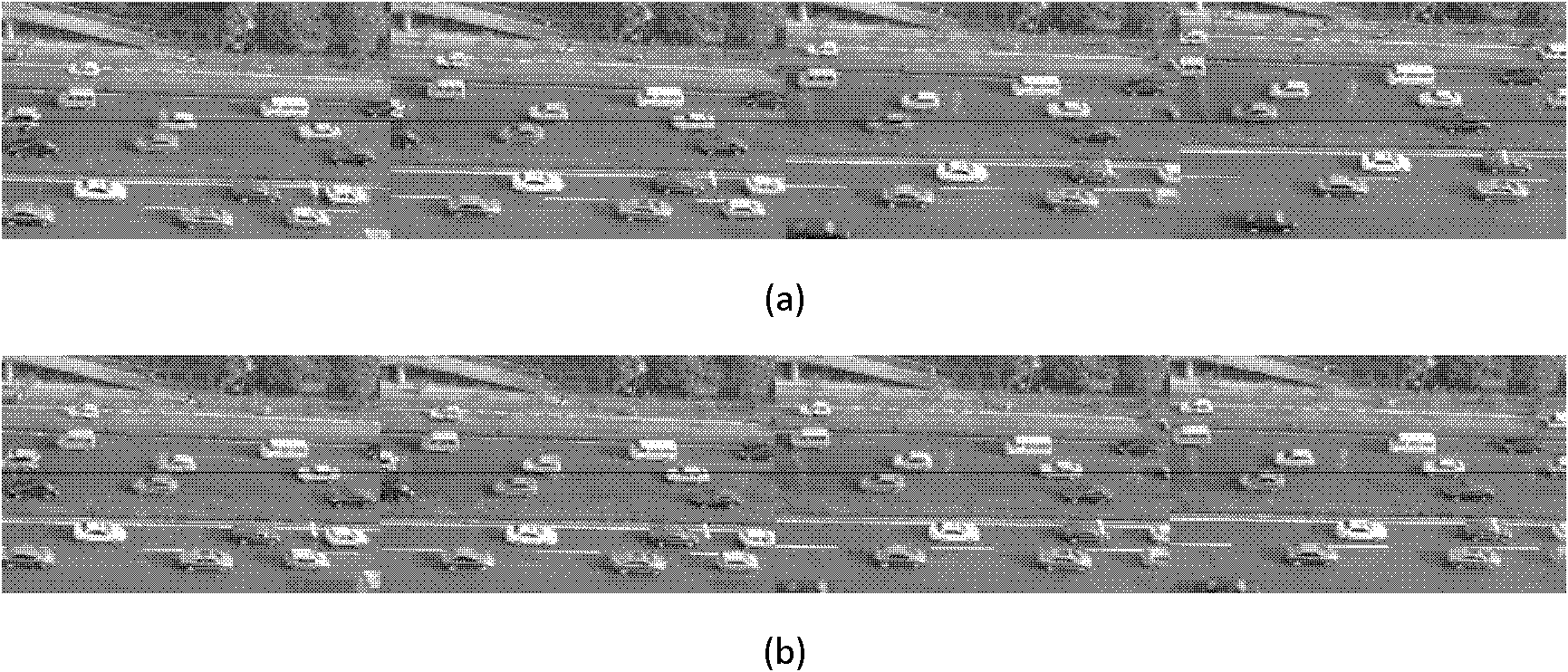

Motion-estimation-based road video stabilization method

InactiveCN102202164AHigh precisionImprove efficiencyTelevision system detailsImage analysisDynamic motionImage sequence

The invention relates to a motion-estimation-based road video stabilization method, which comprises the following steps of: performing nonlinear smooth denoising on an input image; determining a characteristic searching range according to the requirements of a system on accuracy, and acquiring optimal characteristic information; performing cross grayscale projection on a template and a block to be matched, and finding an optimal matched area according to a difference; constructing a dynamic motion model in a recursion way by adopting a Kalman filter with a uniform motion equation, obtaining motion parameters of a camera for describing inter-frame motions caused by the motions of the camera, and identifying and filtering random jitter in an offset sequence obtained by motion estimation; and filling an area losing an image due to the video jitter, and reconstructing adjacent frames by adopting a hybrid Gaussian model and utilizing time relativity between image sequences.

Owner:CHANGAN UNIV +2

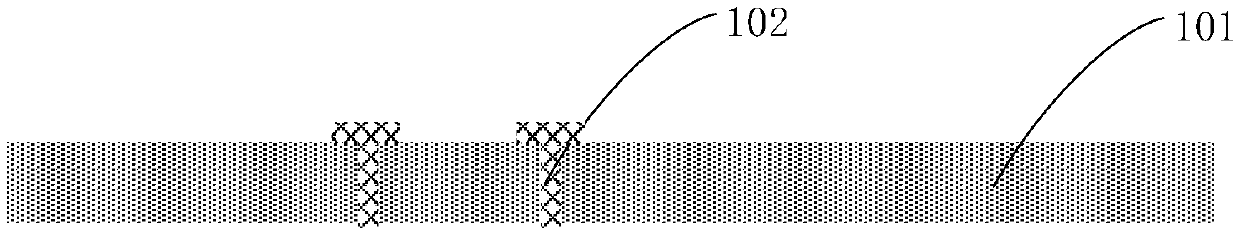

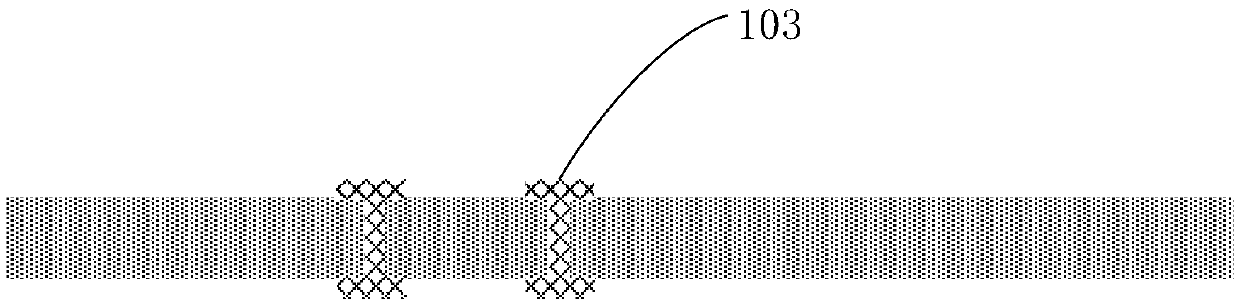

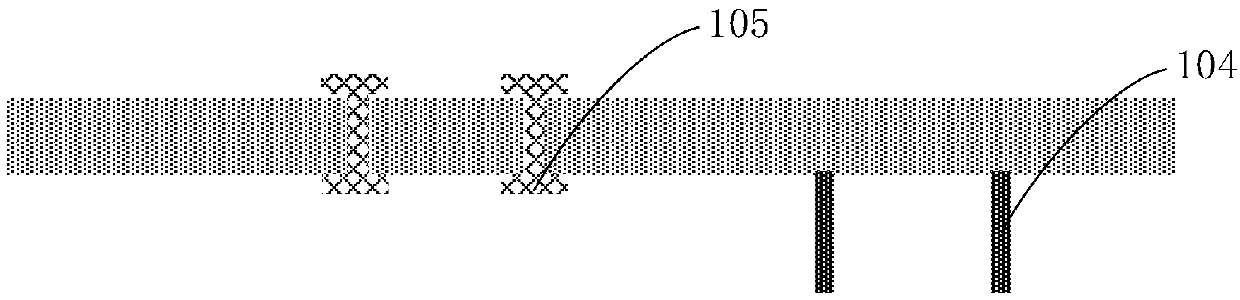

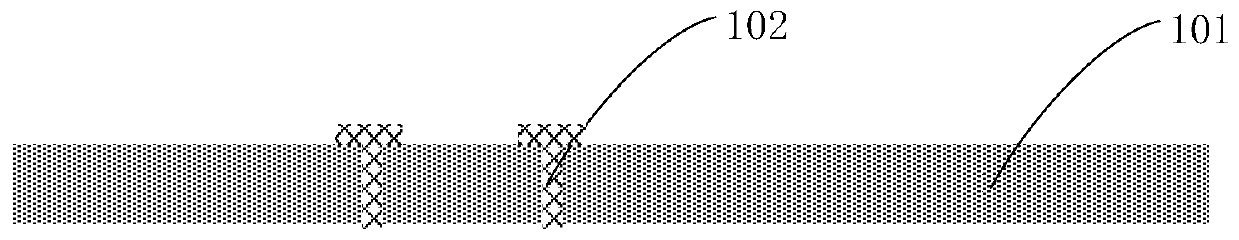

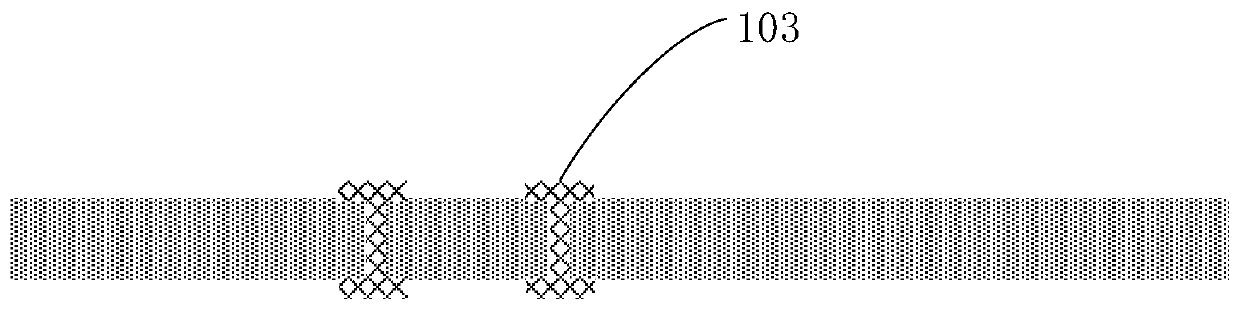

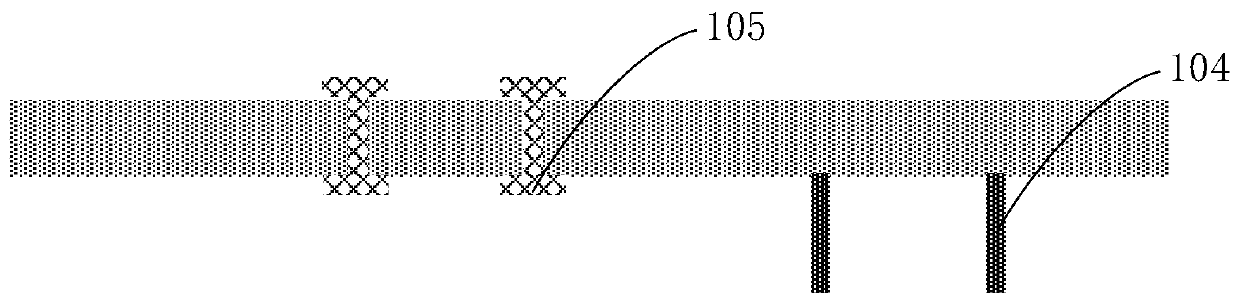

Cavity filling method based on surface data

InactiveCN104463973ATo achieve the purpose of fillingDetails involving 3D image data3D modellingEngineeringVoxel

The invention belongs to the technical field of image processing and provides a cavity filling method based on surface data. The cavity filling method based on the surface data comprises the steps that firstly, voxelization is conducted on the surface of the surface data, a surface cavity in the voxelized surface is filled by means of a gradual interpolation, the internal space of the closed voxelized surface is filled according to the voxelization method, and finally the surface data are re-constructed according to the surface drawing method, so that the purpose of cavity filling is realized. By the adoption of the cavity filling method based on the surface data, abnormal edges of the cavity can be deleted. In addition, the invention correspondingly provides a cavity filling system based on surface data. According to the cavity filling method and system based on the surface data, multiple cavities with any complicated cavity edges can be filled.

Owner:林志均

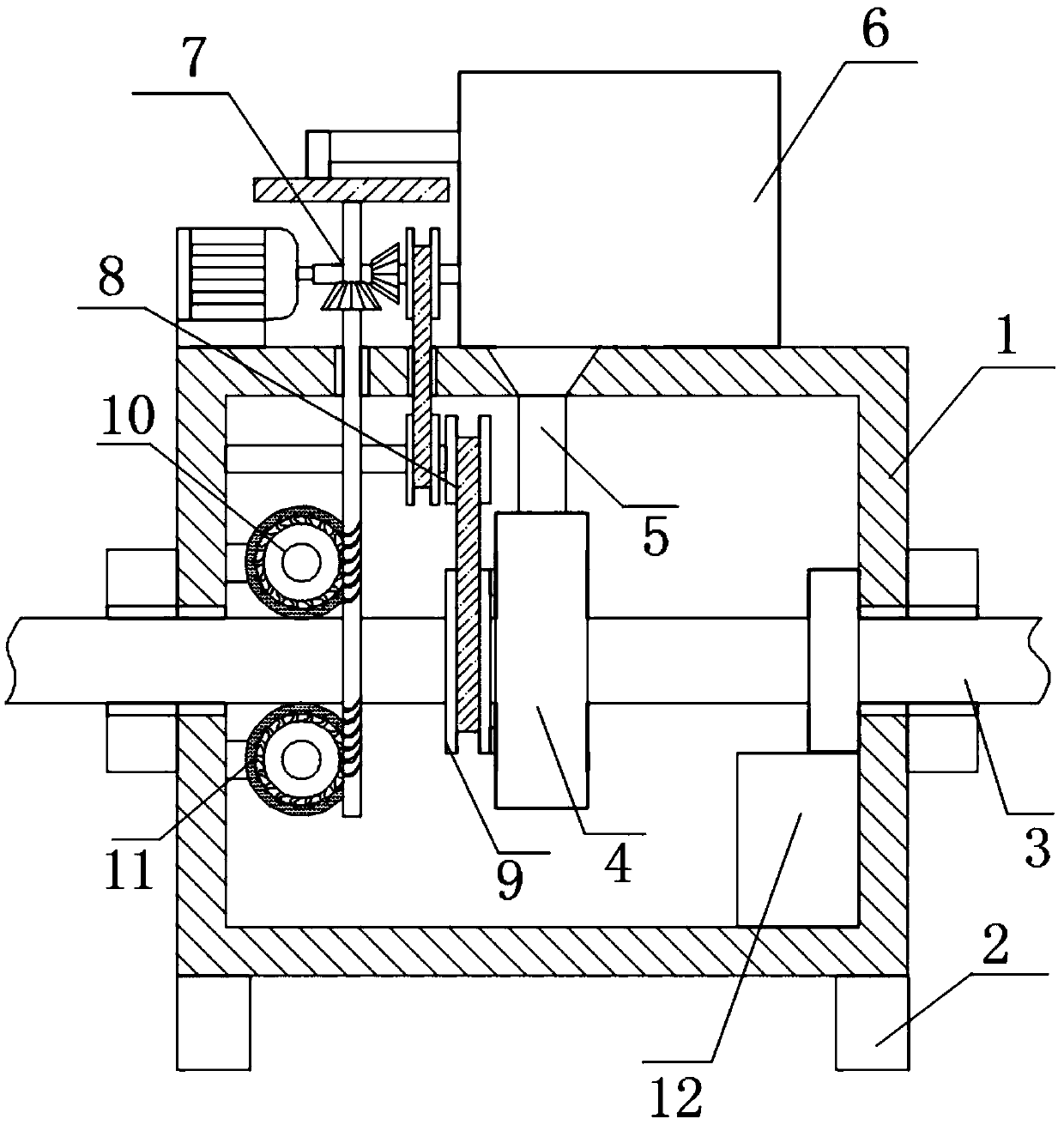

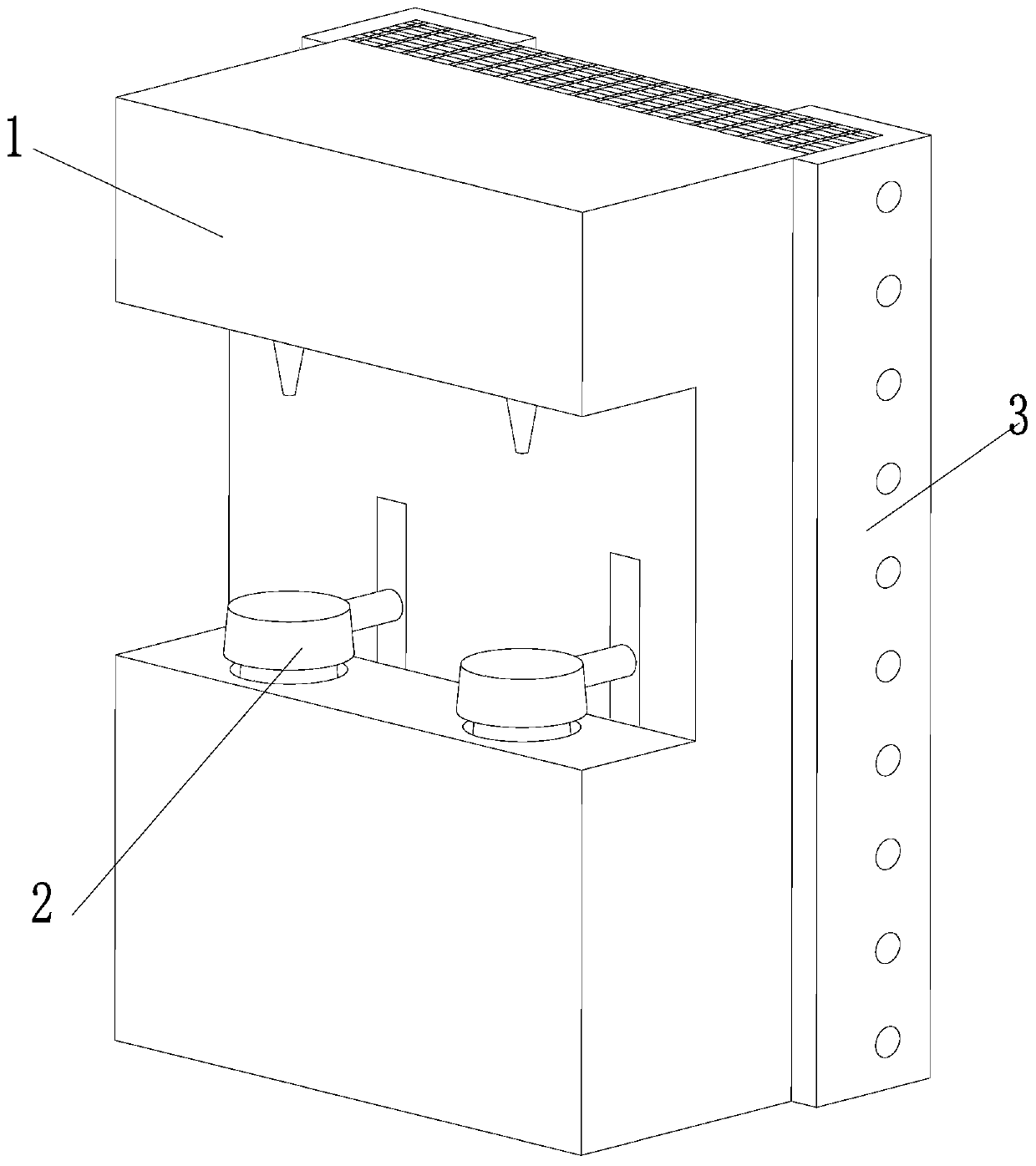

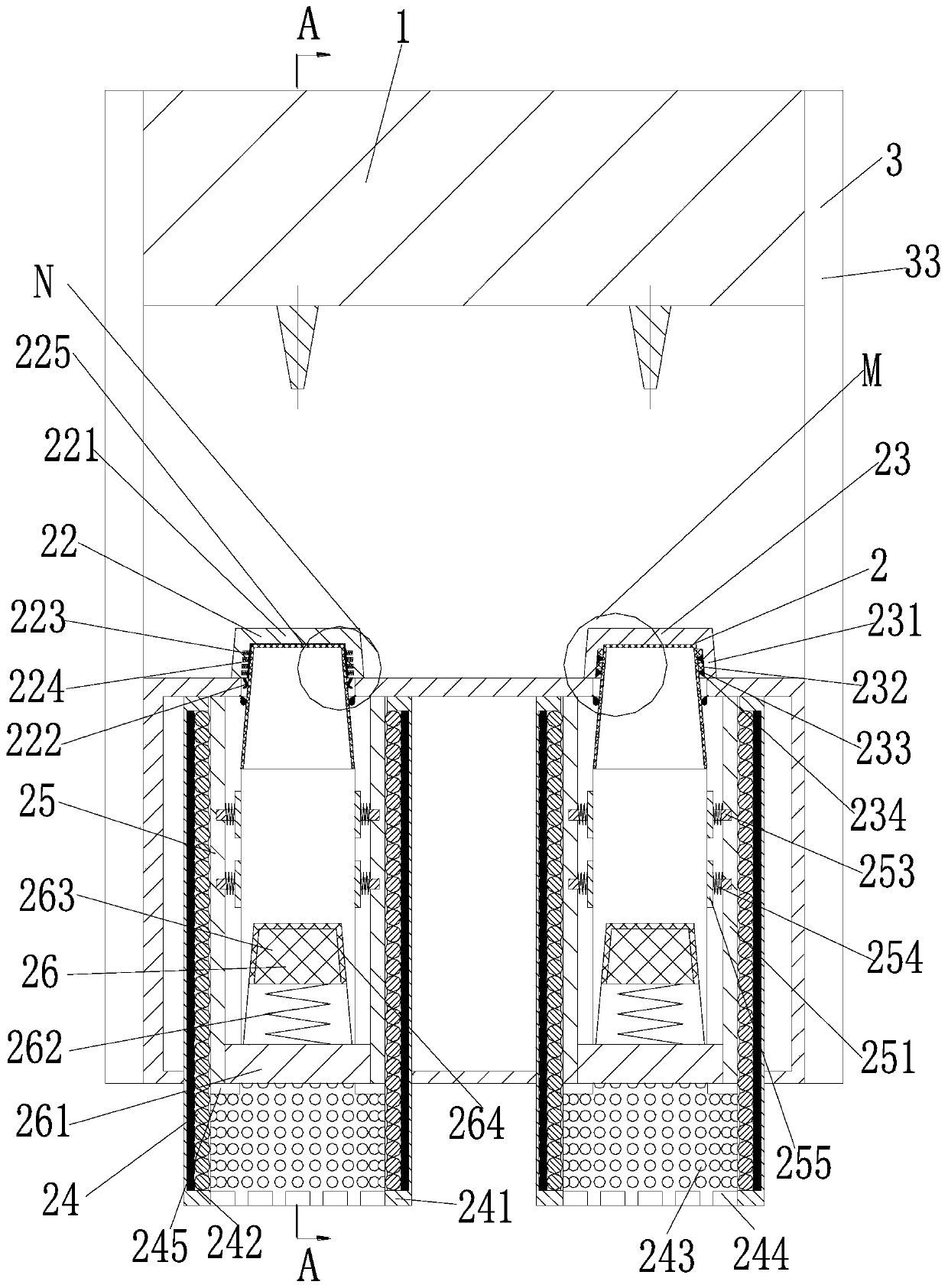

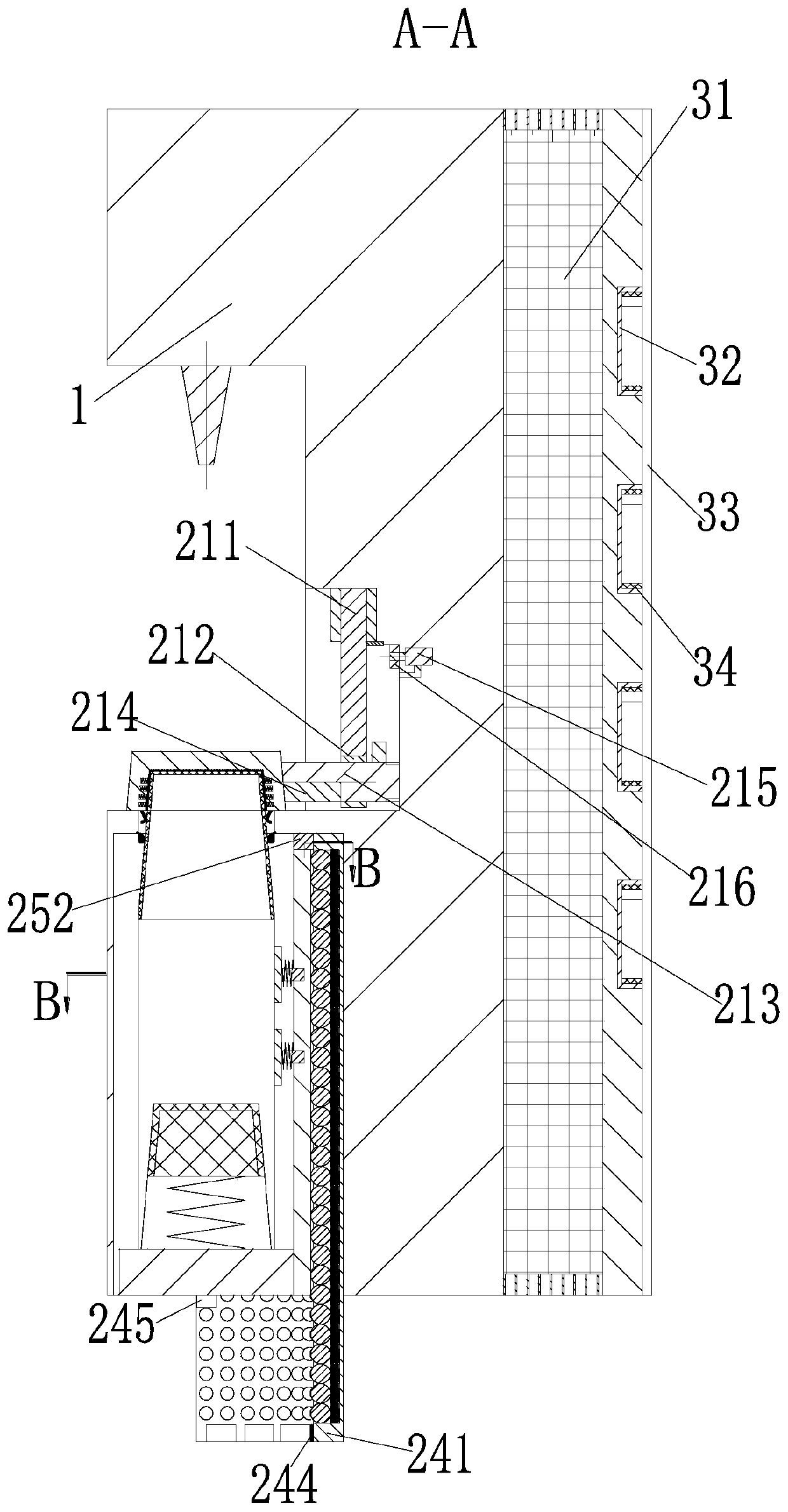

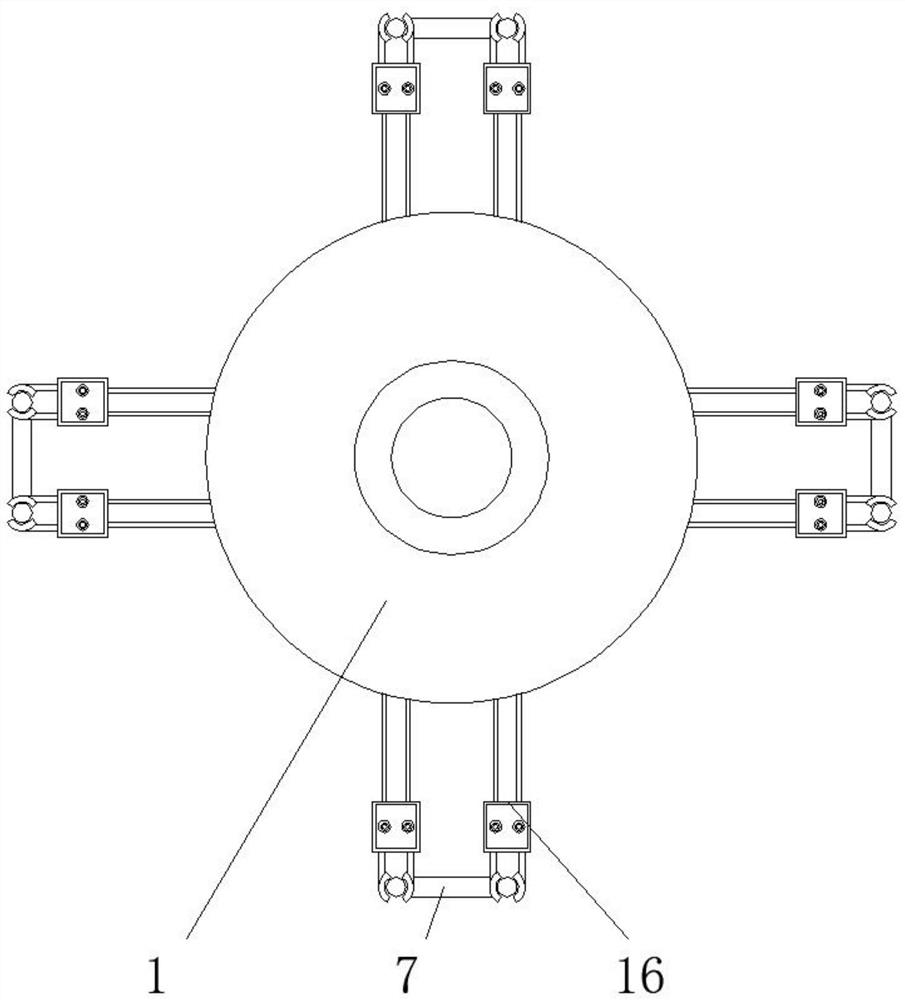

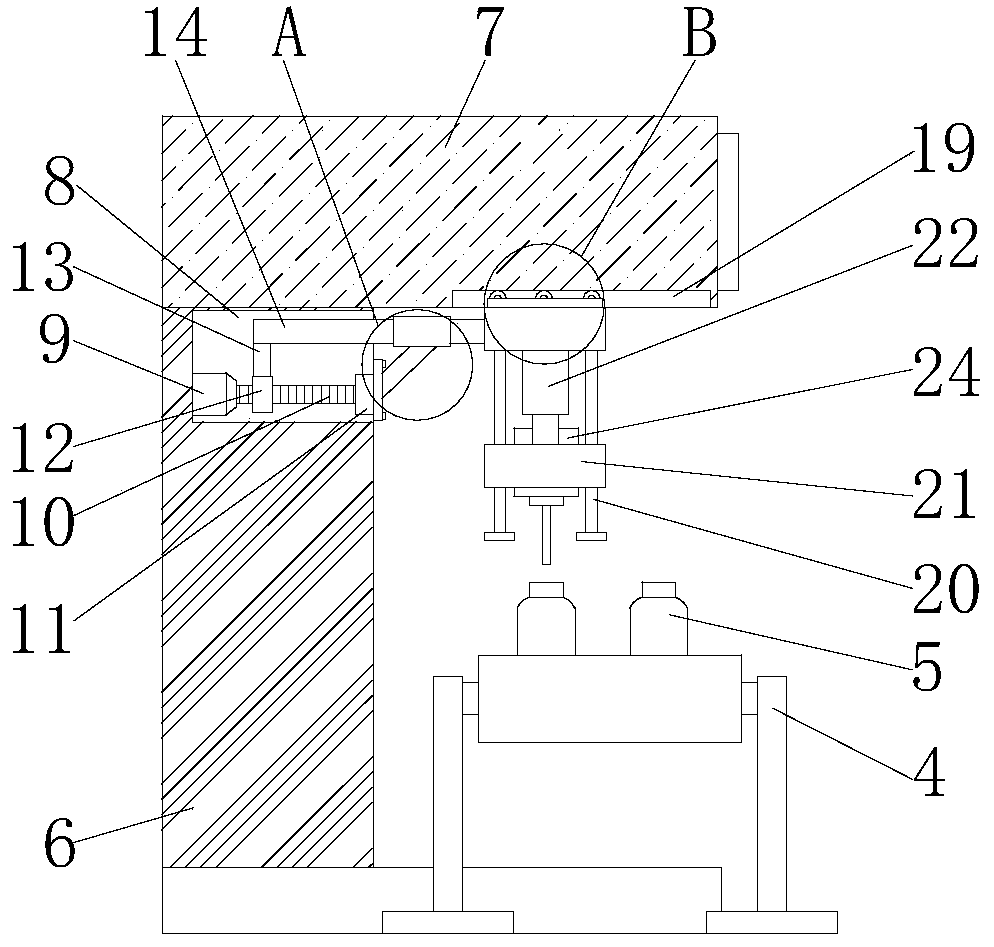

Auxiliary material filling device for cable

InactiveCN109524178AReduce dosageReasonable designCable/conductor manufactureState of artEngineering

The invention provides an auxiliary material filling device for a cable. The device comprises a filling box, a plurality of supporting legs connected at the lower end of the filling box, two symmetriccircular through holes set on the side wall of the filling box, and cable cores slidingly connected in the two circular through holes. According to the device, the deficiencies of the prior art are overcome, the design is reasonable, the structure is compact, grease is uniformly applied to the cable cores through an oil brush in the filling device, therefore, the uniformity of filling is improved, the filling effect is improved, in addition, the cable cores can be driven to automatically move through a rotating wheel, the effect of automatic filling is achieved, the filling efficiency is improved, excess grease can be scraped off through an annular scraper, the amount of grease is saved, the cost is saved, and the device has high practicability.

Owner:天长市运成电缆辅料有限公司

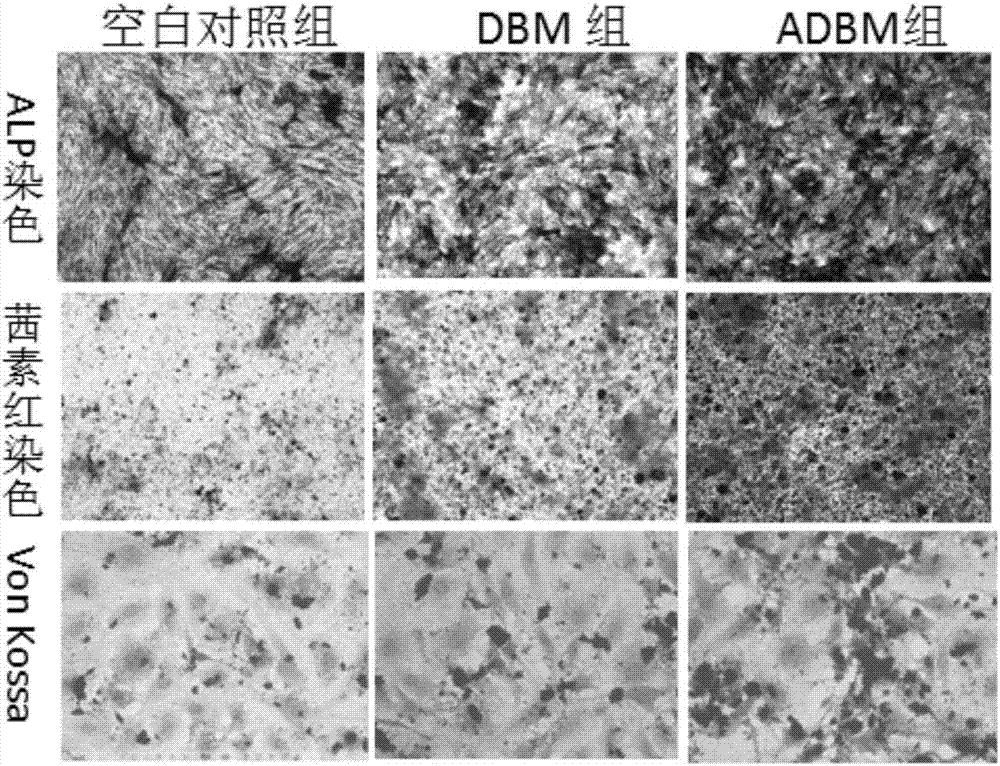

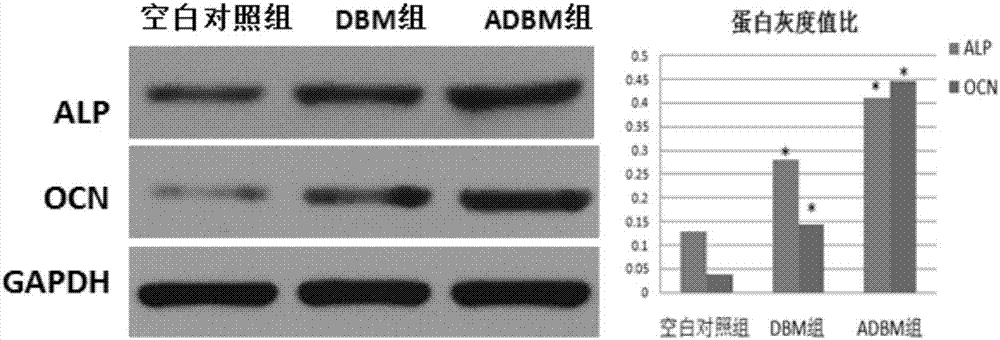

Preparation method of decalcified bone matrix bone-repairing material

InactiveCN107050527ASimple preparation processAchieve bone repairTissue regenerationProsthesisPhosphateBone tissue

The invention discloses a preparation method of a decalcified bone matrix bone-repairing material. The method comprises the following steps: (1) adding alginate into a phosphate buffer solution, and evenly stirring and mixing to obtain 0.5-3% alginate solution; (2) adding decalcified bone matrix powder into the alginate solution, fully stirring, and preparing into 20-100mg / ml suspension; (3) putting the suspension obtained in the step (2) into a mould, dropwise adding a CaCl2 solution into the suspension, standing when the suspension is gelatinized, then taking strip-shaped gel out of the mould, and carrying out freeze drying. The bone-repairing material prepared by the method has good biocompatibility, is capable of inducing the formation of bone tissue components, and enables a new bone to be rapidly formed at the focus position by taking decalcified bone matrix as a support, thus achieving the aims of repairing and filling the bone.

Owner:WUHAN UNIV

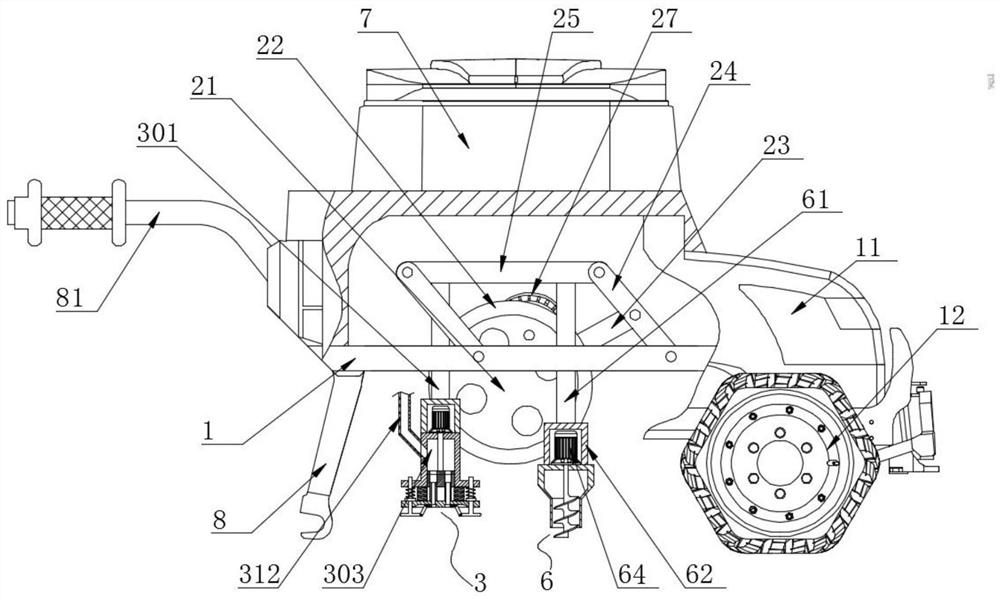

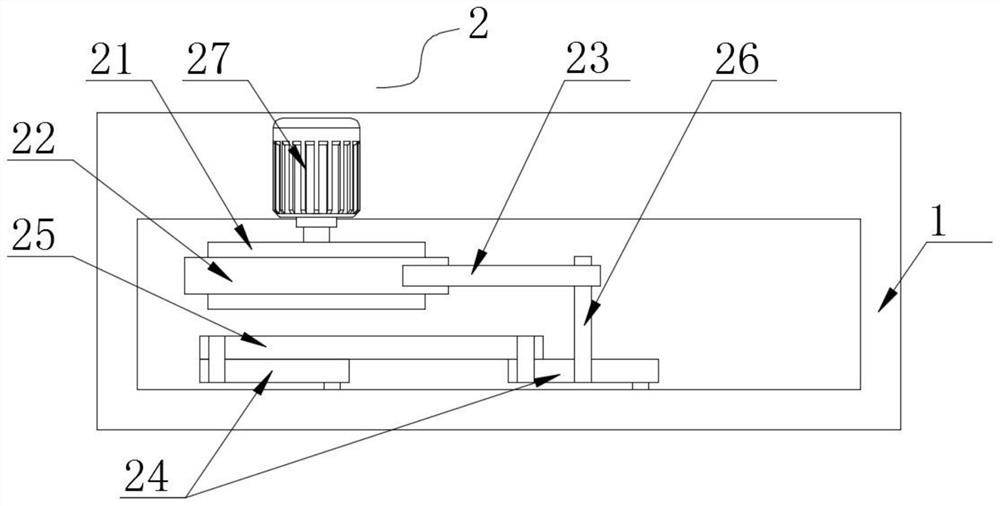

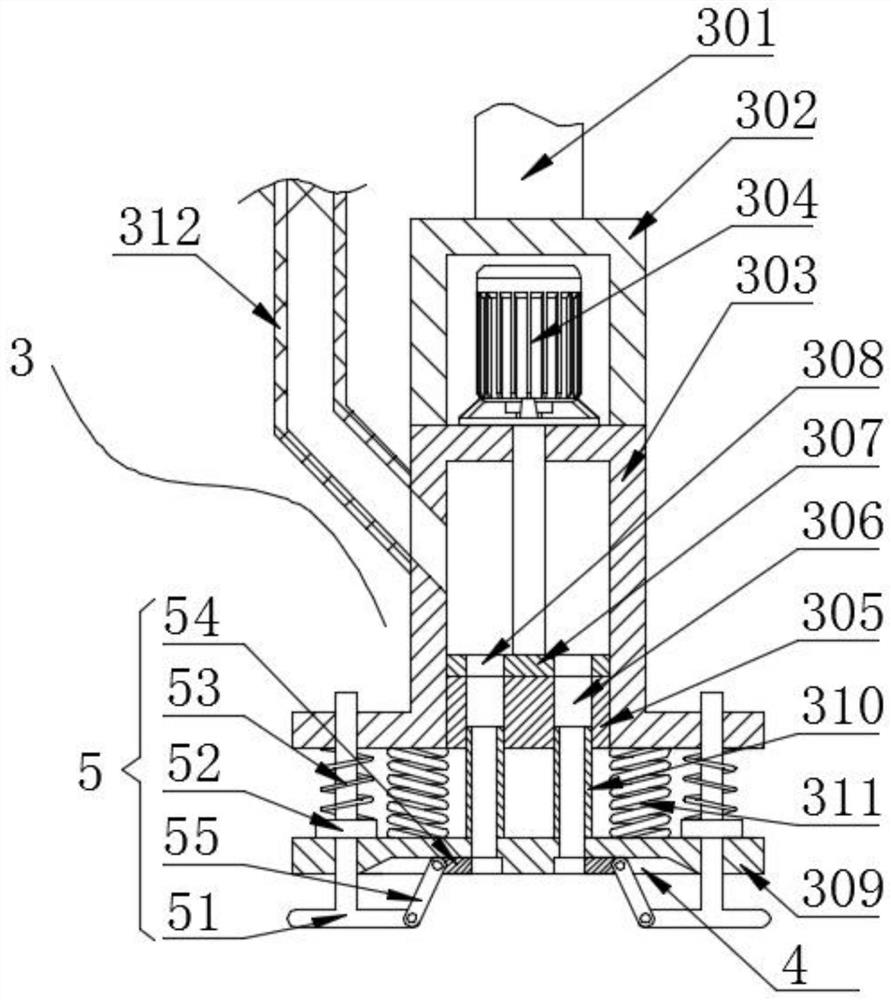

Agricultural seeder

InactiveCN111758333AReduce participationAchieve the purpose of sowingPlantingDibble seedersSeederAgricultural engineering

The invention discloses an agricultural seeder, and particularly relates to the technical field of agricultural machinery, the agricultural seeder comprises a chassis, a machine body is fixedly mounted on the chassis, wheels are mounted at the front end of the chassis, a transmission mechanism is arranged in the middle of the chassis, and a seeding and soil pressing mechanism is arranged on the rear side below the transmission mechanism; a soil digging and filling mechanism is arranged on the front side below the transmission mechanism, and anti-blocking mechanisms are arranged on the two sides of the bottom of the sowing and soil pressing mechanism. Through the arrangement of the wheels, the transmission mechanism, the sowing and soil pressing mechanism, the sliding groove, the anti-blocking mechanism and the soil digging and filling mechanism, the transmission mechanism drives the sowing and soil pressing mechanism and the soil digging and filling mechanism to move up and down in a reciprocating mode, the sowing purpose is achieved through the sowing and soil pressing mechanism, and meanwhile the soil pressing purpose can be achieved; and the purposes of earth excavation and earth filling are achieved through the earth excavation and earth filling mechanism, that is, the functions of earth excavation, sowing, earth filling and earth pressing are sequentially achieved throughthe combination of the sowing and earth pressing mechanism and the earth excavation and earth filling mechanism.

Owner:刘智城

Portable wall-mounted water purifier

ActiveCN111012178AAnti-preventionPrevent the occurrence ofBeverage vesselsProcess engineeringCold drinks

The invention relates to a portable wall-mounted water purifier. The water purifier comprises a water purification tank, a grabbing device and a suspension device, wherein the grabbing device is mounted at the rear end of the water purification tank; the suspension device is mounted at the front end of the water purification tank; the grabbing device comprises a grabbing frame, a first grabbing cylinder, a second grabbing cylinder, a sliding rail, a limiting plate and a containing block. The first grabbing cylinder comprises a first conical cylinder, a reed, a small spring, a frosted block anda rubber sleeve. A disposable paper cup is grabbed and fixed through the grabbing device. A hot drink paper cup and a cold drink paper cup are grabbed by the first grabbing cylinder and the second grabbing cylinder respectively so as to achieve the purpose of automatically grabbing and using paper cups, dust generation, which affects use of the paper cups and causes waste of the paper cups, on the surfaces of the paper cups is effectively prevented. The water purifier can be rapidly fixed to walls and fixing faces with different widths through the suspension device and can be adjusted at will.

Owner:北京怡盛原环保科技有限公司

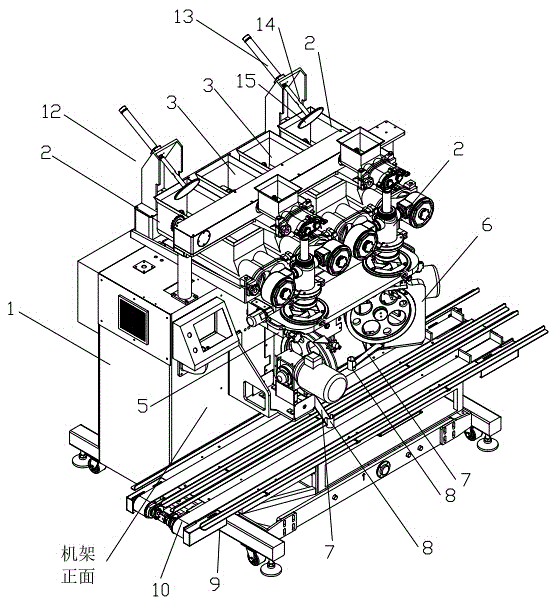

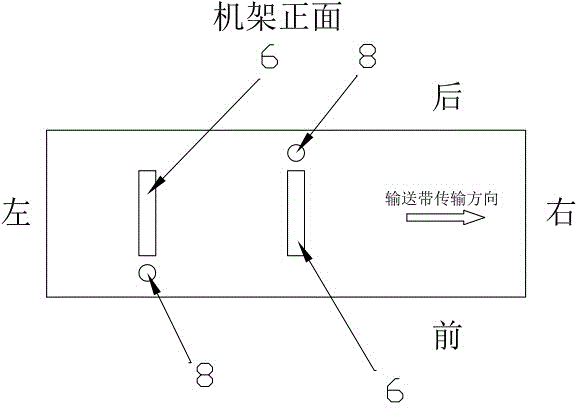

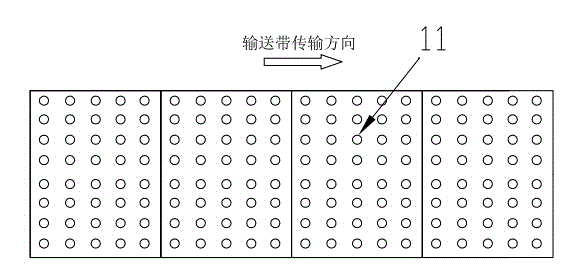

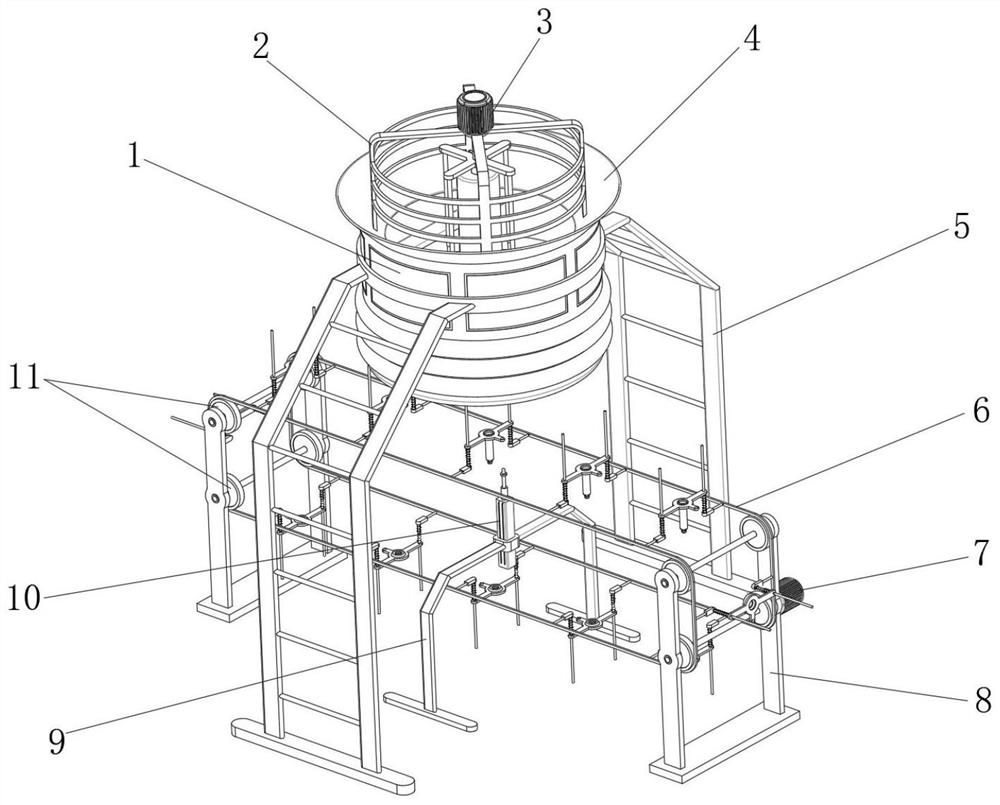

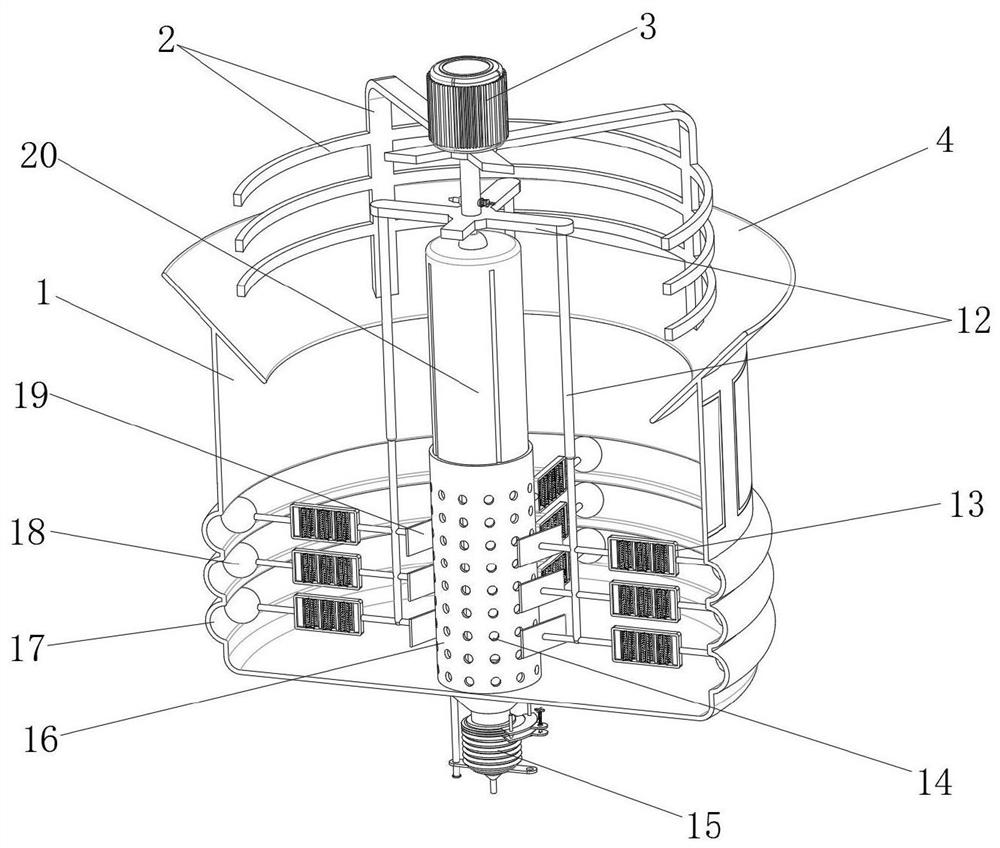

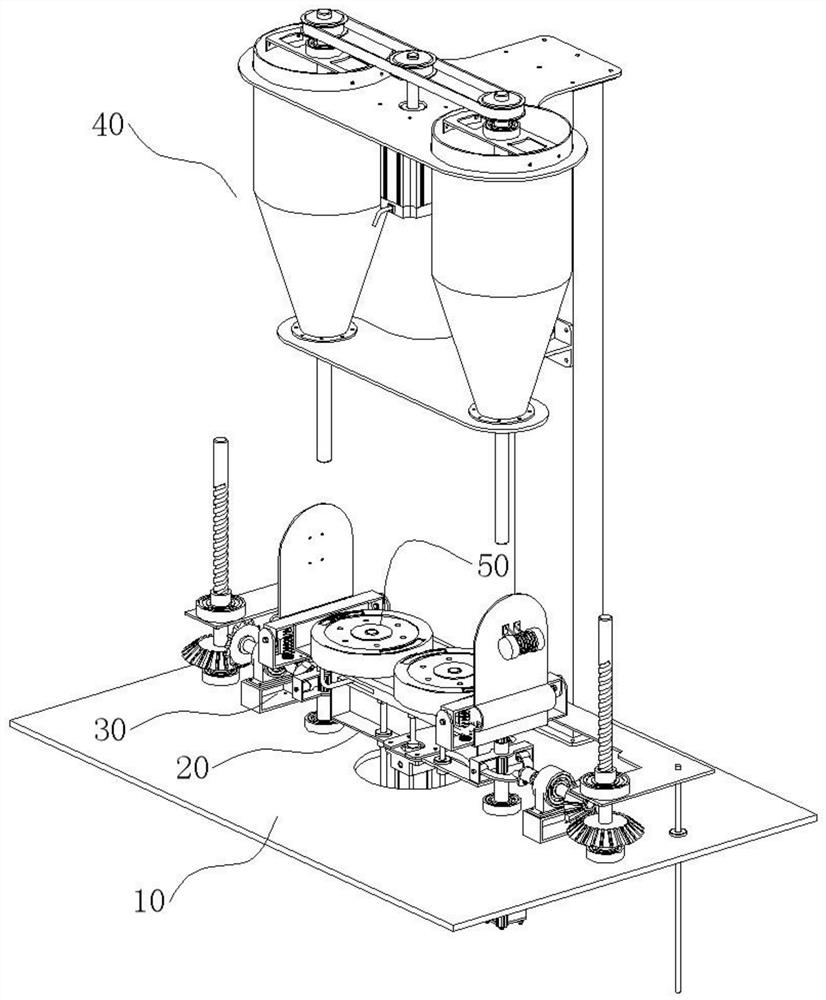

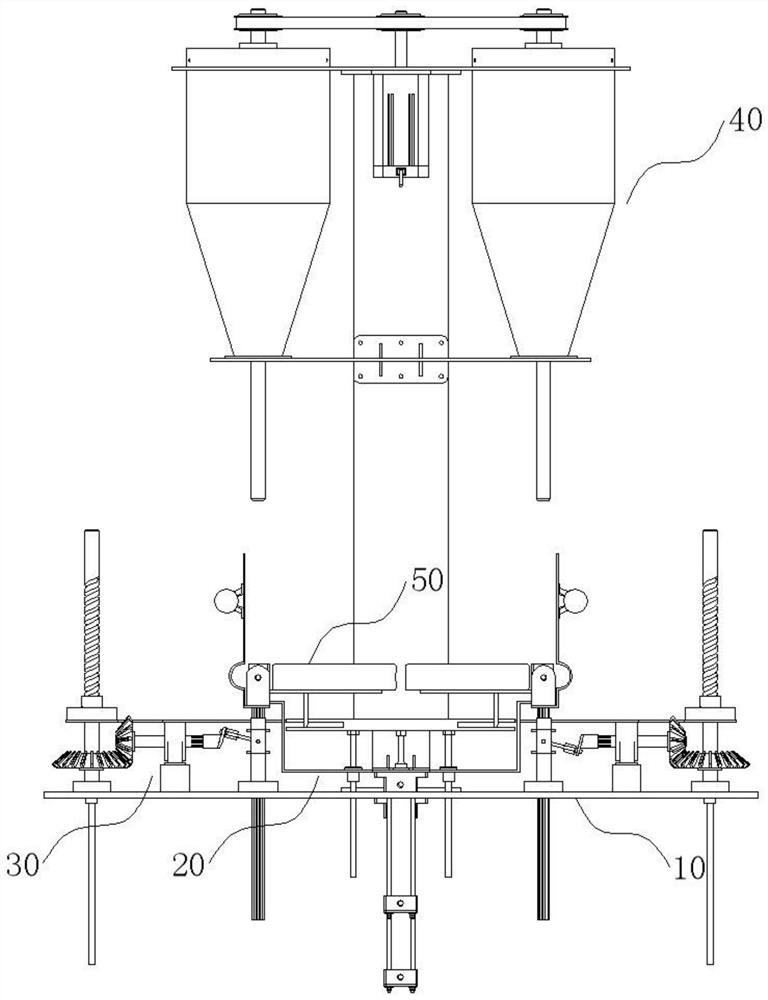

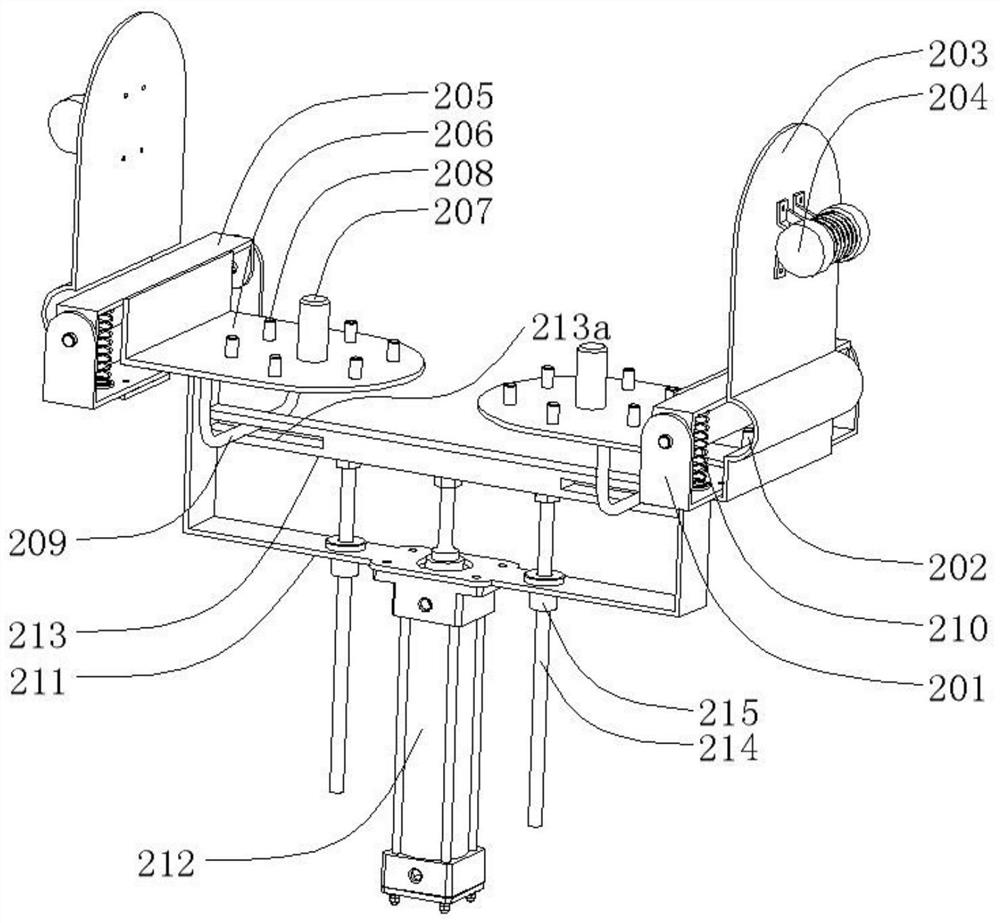

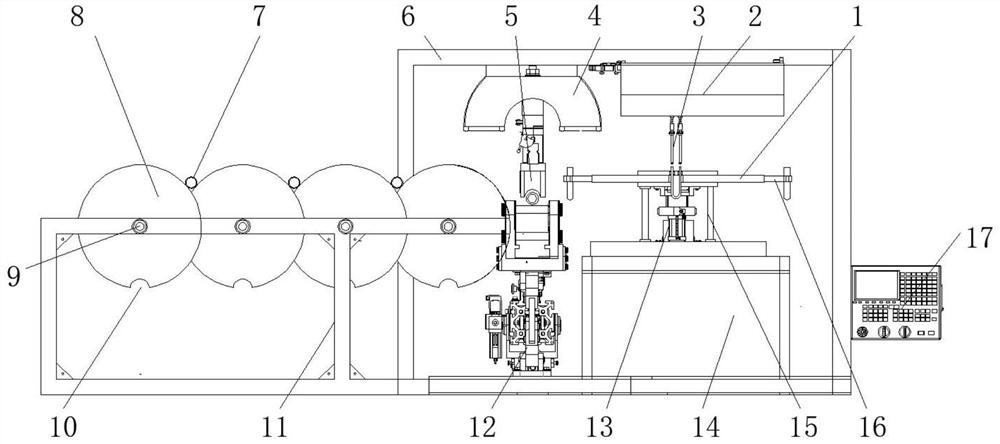

Rounding encrusting machine

InactiveCN104904771ATo achieve the purpose of fillingSave time at workDough shaping and cutting apparatusDough processingConveyor beltFood processing

The invention relates to the field of food processing and specifically relates to a rounding encrusting machine. The rounding encrusting machine comprises a frame, and devices all arranged on the frame, such as a stuffing feeding device, a wrapper feeding device, at least two compound head devices, a cutter device and a rounding device; each compound head device is communicated with one stuffing feeding device and one wrapper feeding device; the cutter device is arranged under each compound head device; the rounding device is arranged under the cutter device. According to the rounding encrusting machine, the falling hoppers are arranged in a staggered manner to avoid the case that the falling hoppers are arranged together; when a conveyor belt is transversely arranged on the right side of the frame, the rounded sweet dumplings fall into grooves in different transverse rows and different vertical rows on a holding tray due to the falling hoppers arranged in the staggered manner; as a result, the case that the sweet dumplings simultaneously fall into the same row or the same column is avoided.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Ice cream extruder capable of automatically filling and feeding

InactiveCN112616989AAchieve the purpose of extrusionEasy to holdFrozen sweetsChemistryComposite material

The invention discloses an ice cream extruder capable of automatically filling and feeding. The ice cream extruder comprises filling equipment, wherein a filling cavity with a forward opening is formed in the filling equipment; a communicated working cavity is formed in the bottom wall of the filling cavity; an extrusion spray pipe is fixedly arranged in the upper end wall of the filling cavity; the lower section of the extrusion spray pipe is in a sharp corner shape; and an extrusion cavity which is through up and down is formed in the extrusion spray pipe. The ice cream extruder disclosed by the invention is mainly applied to manufacturing and filling of ice cream in daily life; in the filling process, the aim of extruding the ice cream is achieved by rotation of extrusion blades; a pushing mechanism is triggered by movement of a rectangular threaded block, so that the ice cream can spirally fall into an ice cream barrel and the aim of filling is further achieved; and meanwhile, the filled ice cream can slide upwards by a pushed block, so that people can more conveniently hold the ice cream and the effects of convenience and rapidness are further achieved.

Owner:深圳市荣裕达商贸有限公司

Nursery stock transplanting device

InactiveCN112753524AImprove survival rateRealize the purpose of scraping soil and digging pitsTransplantingForestryHydraulic cylinderAgricultural engineering

The invention discloses a nursery stock transplanting device, and particularly relates to the technical field of nursery stock transplanting. The nursery stock transplanting device comprises a bottom plate, walking wheels are installed on the two sides of the bottom plate, a mounting frame is arranged above the bottom plate, hydraulic cylinders are arranged on the two sides between the bottom plate and the mounting frame, and the bottom plate is fixedly connected with the mounting frame through the two hydraulic cylinders; a transplanting mechanism is arranged between the bottom plate and the mounting frame, the transplanting mechanism comprises a hollow cylinder, an annular groove is formed in the outer side of the bottom end of the hollow cylinder, the annular groove comprises two horizontal grooves and two V-shaped grooves, and the horizontal grooves and the V-shaped grooves are alternately arranged and connected end to end. According to the nursery stock transplanting device, the purposes of scraping soil and digging pits are achieved by rotating the hollow cylinder for half a circle and moving two soil scraping plates in the inclined upward direction, meanwhile, saplings in object carrying hoppers fall into the pits, and then the purpose of filling the soil is achieved by moving two soil pushing plates to the middle, so that the purpose of planting is achieved; compared with manual work, the planting speed is high, and the planting efficiency is high, and the survival rate of the saplings is improved.

Owner:罗琪

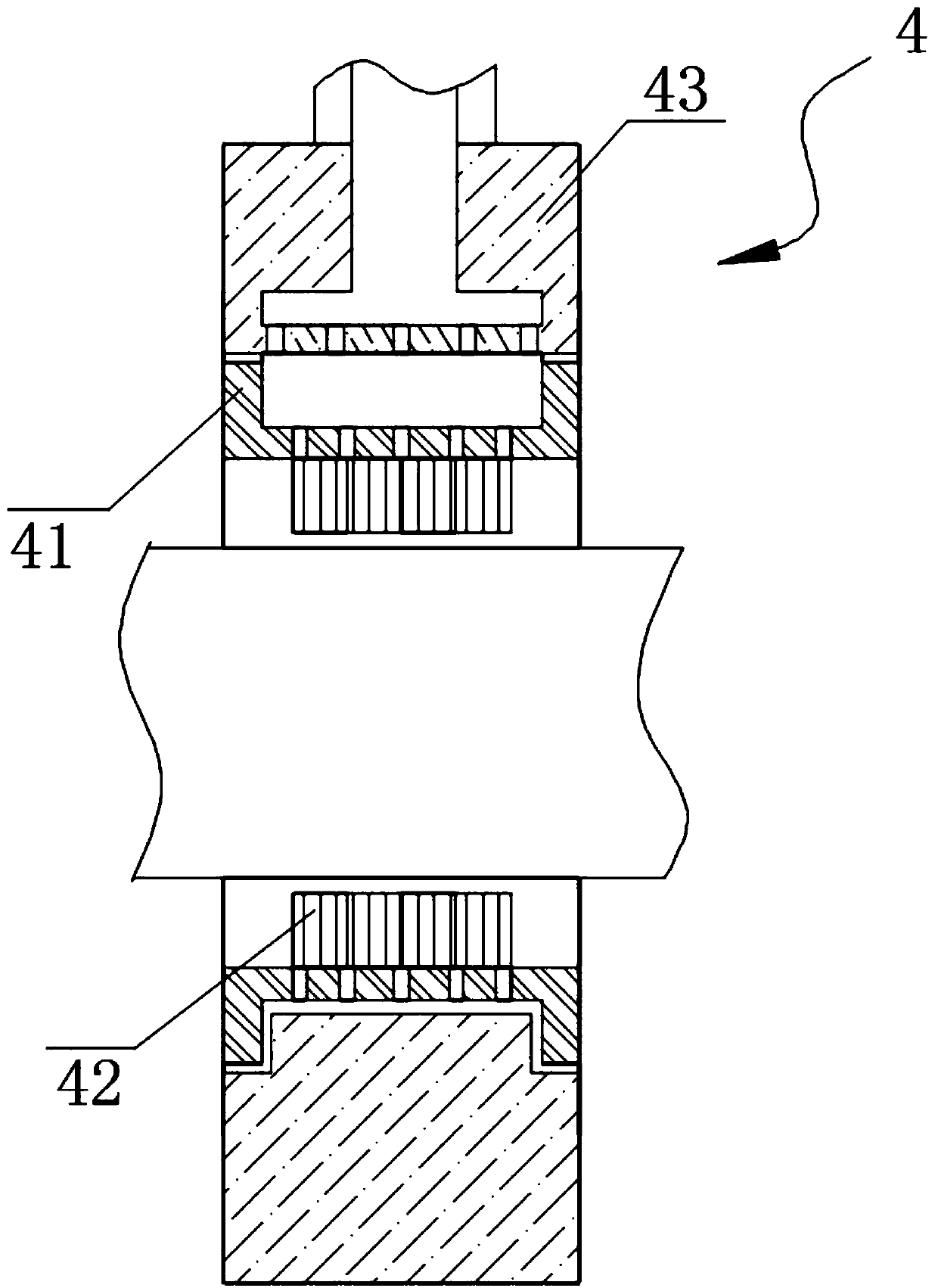

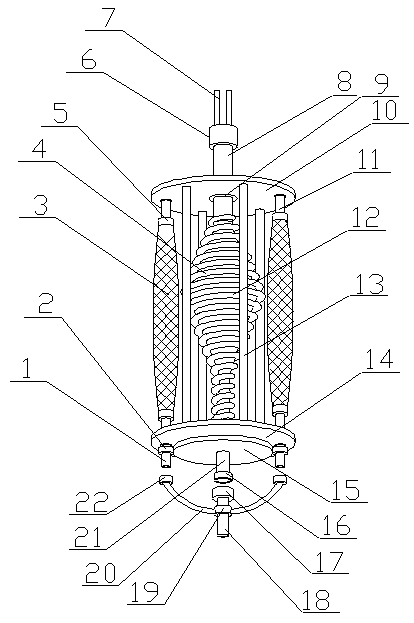

Jack-type ultra-deep TSV interconnected radio frequency chip system-level packaging process

ActiveCN110010484ATo achieve the purpose of fillingSolid-state devicesSemiconductor/solid-state device manufacturingRadio frequencySystem in package

The invention discloses a jack-type ultra-deep TSV interconnected radio frequency chip system-level packaging process which comprises the steps of (101) the preliminary processing of a cover plate, (102) cover plate thinning processing, (103) intermediate layer processing, (104) base processing, and (105) packaging. The present invention provides the jack-type ultra-deep TSV interconnected radio frequency chip system-level packaging process with ultra-deep TSV hole filling.

Owner:浙江集迈科微电子有限公司

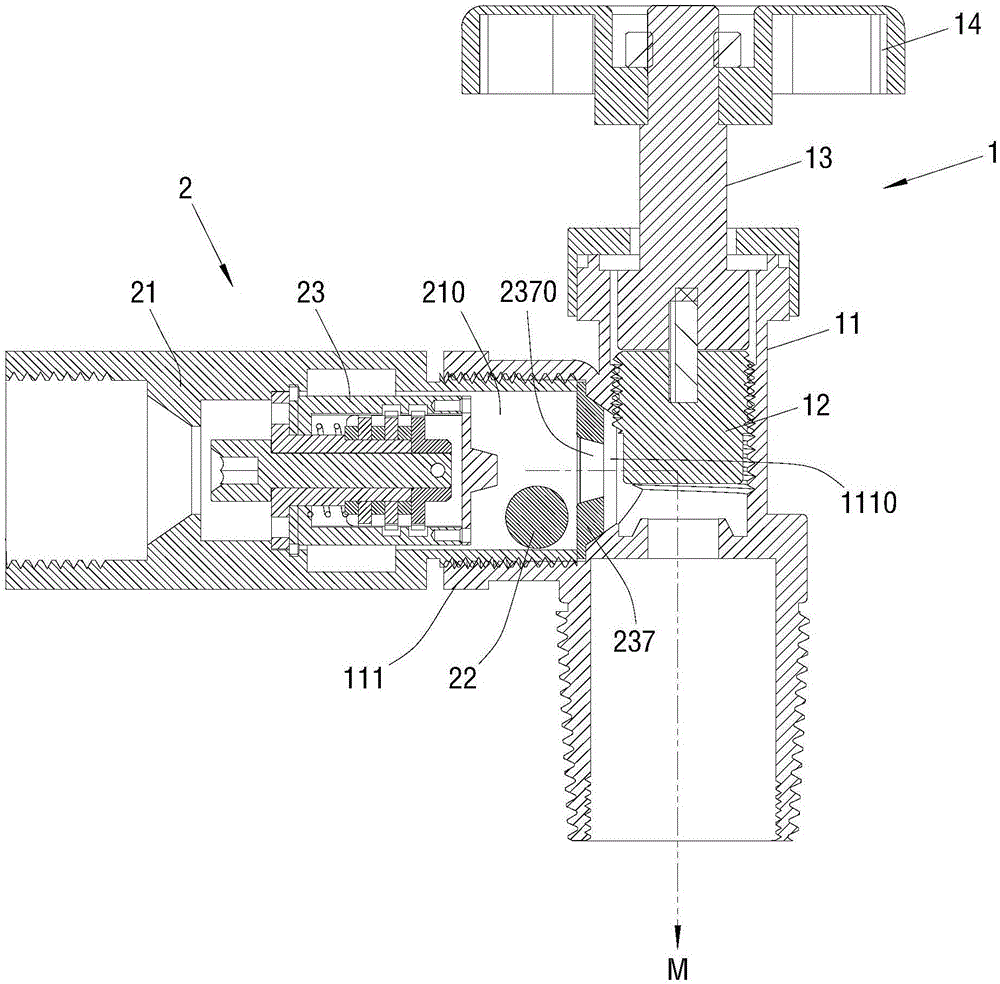

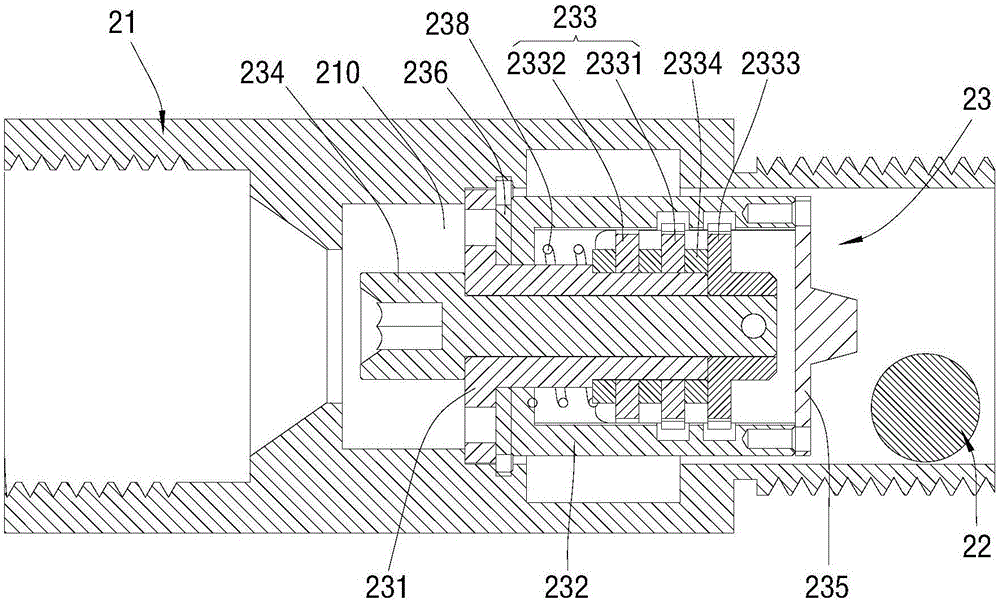

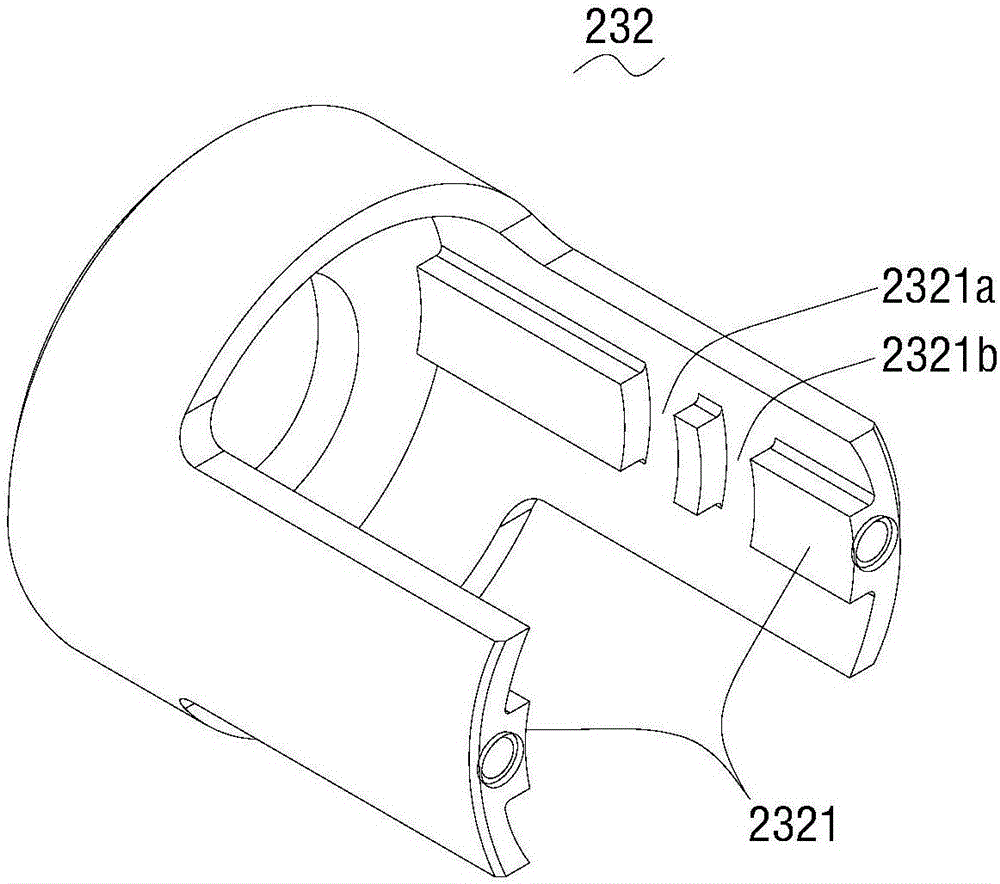

Coded lock valve structure

ActiveCN106567931ALimited filling and high safetyEasy to operateLift valvePreventing unauthorised/accidental actuationGas cylinderEngineering

The invention relates to the technical field of structures of gas cylinder valves and discloses a coded lock valve structure. The coded lock valve structure comprises a valve assembly which comprises a valve body with a gas channel; the valve body is provided with a coded lock assembly capable of controlling the on-off of the gas channel; and the coded lock assembly comprises a fixing barrel connected to the valve body and communicated with the gas channel, a sealing ball movably arranged in the fixing barrel and used for blocking the gas channel, and a coded lock arranged between the fixing barrel and the valve body and capable of abutting against and ejecting the sealing ball so as to remove blocking of the sealing ball on the gas channel. In this way, by arranging the sealing ball and the coded lock matched with the sealing ball in an abutting and ejecting manner in the fixing barrel, in the locked state of the coded lock, the coded lock is separated from the sealing ball, and filling of fluid can push the sealing ball to perform sealing and blocking so as to block the gas channel and achieve the purpose of limiting filling; and in addition, in the unlocked state of the coded lock, filling of the fluid can push the coded lock to make the coded lock abut against and eject the sealing ball so as to remove blocking on the gas channel, the filling purpose can be achieved, and the valve structure is high in filling limiting safety and easy to operate.

Owner:SHENZHEN LANYANG TECH

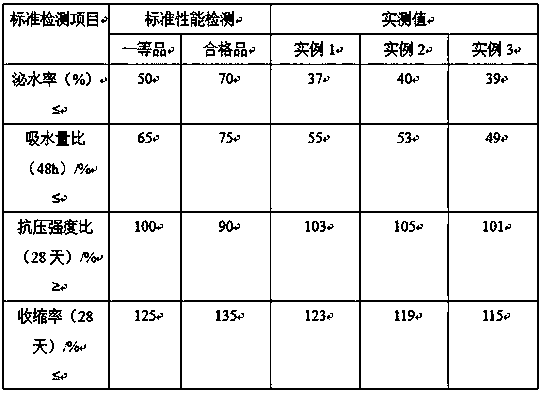

Preparation method of waterproof compacting agent for concrete

The invention relates to a preparation method of a waterproof compacting agent for concrete, and belongs to the technical field of preparation of additives of building materials. According to the preparation method, carboxyl-containing glycine serves as a raw material; the glycine is subjected to epoxy modification under alkaline conditions, and the number of active groups of the modified glycine can be increased; the modified glycine, serving as a complexing agent, reacts with calcium carbonate to generate a soluble calcium complex; the calcium complex can diffuse into the concrete spontaneously along with water, and reacts with silicate in the cement to generate insoluble crystals, and the effects that the strength and waterproofness of the concrete are enhanced while concrete gaps are filled are achieved; and the complexing agent is capable of circularly reacting, lithium silicate can react with free calcium in the cement to generate pectolite gelatin to fill the concrete gaps, and the strength and waterproofness of the concrete are improved. The waterproof concrete compacting agent prepared through the preparation method is good in waterproofness, the strength of the concrete is not prone to being reduced, fracturing is not prone to occurring in the use process, and the preparation method has wide application prospects.

Owner:深圳市五山新材料股份有限公司

A kind of preparation method of concrete waterproof compacting agent

Owner:深圳市五山新材料股份有限公司

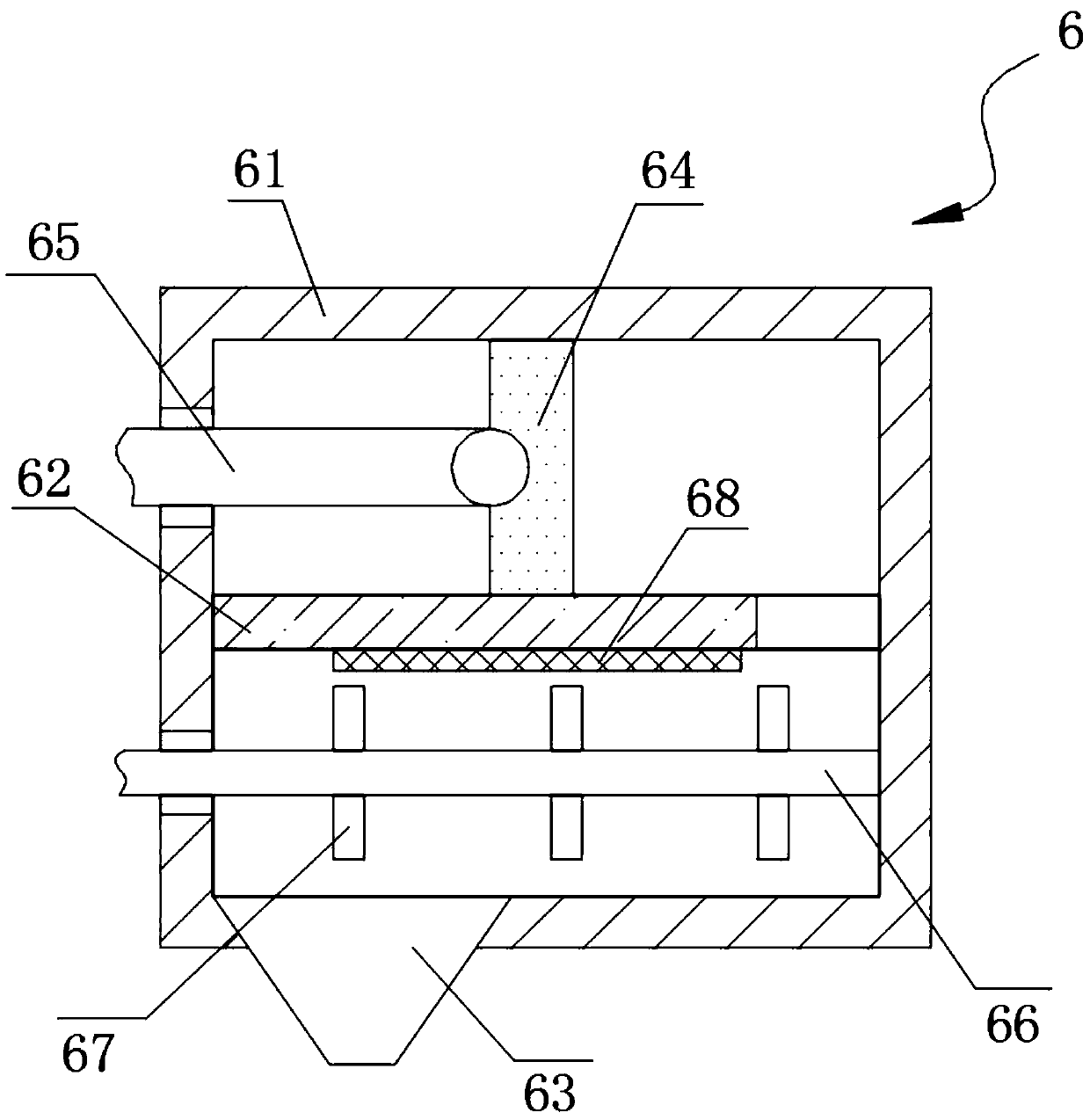

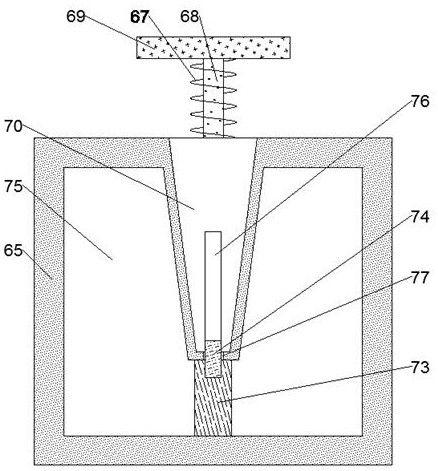

Nasal allergen blocking ointment formula and production equipment thereof

PendingCN114834659ATo achieve the purpose of fillingChange volumeRotary stirring mixersWrapper twisting/gatheringWhite petrolatumGlycerol

The invention discloses a nasal allergen blocking ointment formula and production equipment thereof, and relates to the technical field of nasal anti-allergic ointment. Ointment products of different specifications are prepared in order to facilitate filling; the equipment comprises a preparation tank and a conveying mechanism, a stirring mechanism is arranged in the preparation tank, a filling mechanism is arranged at the bottom of the preparation tank, and the preparation tank is mounted above the conveying mechanism through a first mounting frame; the ointment is prepared from the following raw materials in parts by weight: 65-80 parts of white vaseline, 6.5-8 parts of glycerol monostearate and glycerol distearate, 4-6.5 parts of liquid paraffin, 3-7 parts of PEG40 hydrogenated castor oil, 1-3 parts of menthol and 1-1.5 parts of wool fat. During filling, the carrying frame and the ointment container are jacked up through the jacking mechanism, the bottom end of the filling pipe is inserted into the ointment container, the extrusion plate continues to be jacked upwards, then the elastic bag is extruded, medicine in the elastic bag is extruded into the ointment container, and the purpose of filling is achieved.

Owner:娄飞

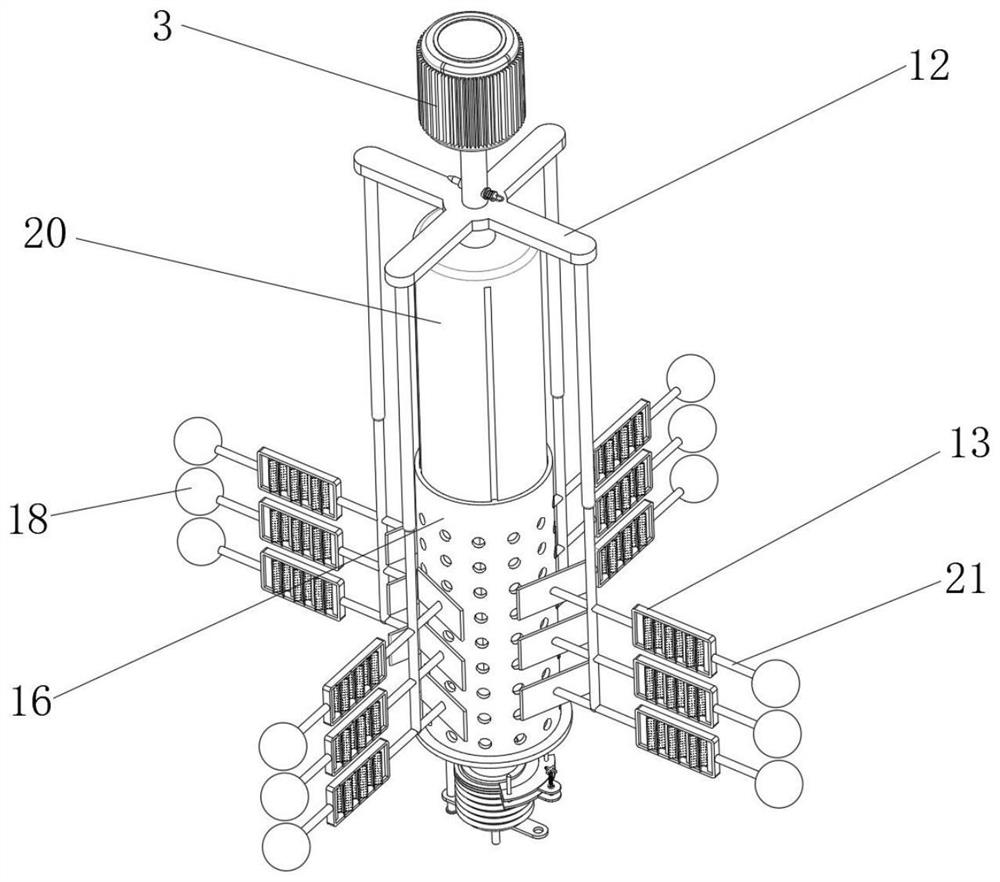

Food processing type oyster sauce filling head

The invention discloses a food processing type oyster sauce filling head, and particularly discloses a filling head device. The filling head device has the advantages that after oyster sauce is heated, blockages on a filtering screen cylinder can be washed out through the rotation of the filter screen cylinder, and the filter screen cylinder can be prevented from being blocked. The filling head ischaracterized in that a main fixing plate is arranged right above an auxiliary fixing plate and is connected to the auxiliary fixing plate through a plurality of connecting rods; the distance betweenevery two adjacent connecting rods is equal; the main fixing plate and the auxiliary fixing plate are of circular-plate-shaped structures and are equal in size; a heating cylinder is arranged betweenthe main fixing plate and the auxiliary fixing plate; the two ends of the heating cylinder are arranged in the middle of the main fixing plate and the middle of the auxiliary fixing plate through supporting bearings separately; the heating cylinder is spindle-shaped and is made of copper; a spiral blade is arranged on the heating cylinder and is made of copper; a plurality of grooves are formed in the surface of the spiral blade; one end of a hollow rotating rod is connected to one end of the heating cylinder; a connecting sleeve sleeves the other end of the hollow rotating rod; and a heatingpipe is arranged in the heating cylinder and is spirally distributed.

Owner:徐州果姿电子商务有限公司

A method of recycling waste plastics to prepare fillers

InactiveCN104326697BSolve processing problemsReduce manufacturing costSolid waste managementAdhesiveCitric acid

The invention relates to a method for preparing a filler by recycling waste plastic. The method comprises: (1) weighing 9-20 parts of a modifier, 20-40 parts of plastic powder, 26-50 parts of an adhesive, 45-100 parts of stone powder, and 1-15 parts of wood powder; (2) carrying out stirring mixing on the modifier and the plastic powder, standing for 15-30 min, adding the adhesive, the stone powder and the wood powder, and continuously carrying out mixing stirring to obtain a mixture for spare; and (3) adjusting the pH value of the mixture with citric acid to 5.5-6.5 so as to obtain the filler. According to the present invention, the recycled waste plastic is adopted to process into the filler, the filler provides the good filling effect on the holes on the Eucalyptus wood plate surface, the Eucalyptus wood plate is slightly acidic, and the prepared filler and the Eucalyptus wood plate have the similar characteristic and are easily bonded so as to achieve the filling purpose; and the recycled plastic is adopted as the filler, such that the method is the process with characteristics of turning of waste into treasure and environmental protection, the filler production cost is reduced, and the problem that the plastic in the garbage is difficultly treated is solved.

Owner:GUANGXI DINGJIAN PLASTIC PROD CO LTD

Press-in material for blast furnace hearth

The invention relates to the field of refractory materials for an iron-making blast furnace, in particular to a press-in material as filler for gaps of a blast furnace hearth. The press-in material comprises anthracene oil, SiC powder, graphite powder and an auxiliary binder. A preparation method of the press-in material comprises the following steps: the anthracene oil is added to a mixed material of the SiC powder and the graphite powder, the weight ratio of the anthracene oil to the mixed material is 3:1, and the mixture is heated and distilled; after distillation, samples are taken for component test, and the samples are taken out and cooled after the test result is qualified. The press-in material has good flowing property, the heat conduction coefficient is close to that of a carbon brick material, the press-in material can solidify quickly at a high temperature to block the gaps, so that gas leakage of the blast furnace hearth can be avoided, the thermal conductivity of the blast furnace hearth can be enhanced, and the press-in material has higher practical value.

Owner:SHANDONG IRON & STEEL CO LTD

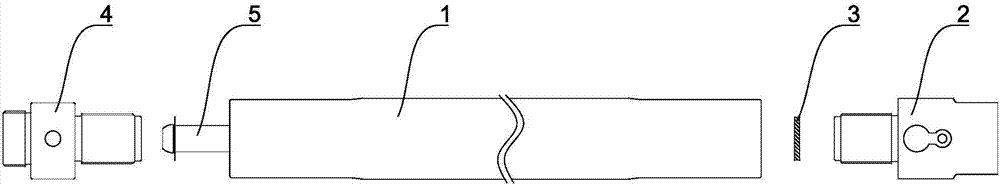

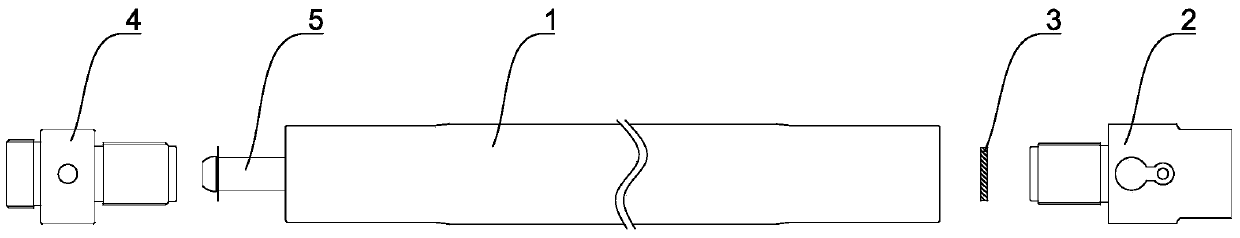

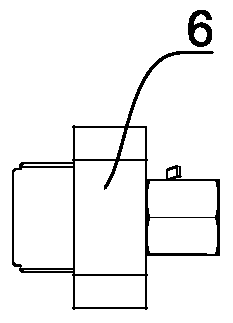

Passive automatic-flow type filling method of carbon dioxide fracturing device

ActiveCN107304675AEasy to operateLow costDisloding machinesContainer filling methodsLiquid stateLiquid carbon

The invention discloses a passive automatic-flow type filling method of a carbon dioxide fracturing device. The method comprises the following steps: rotatably mounting a filling head on a filling end of a fracturing device main pipe, and rotatably mounting a simple head to an energy release end of the fracturing device main pipe; connecting an output valve of a liquid carbon dioxide tank with a filling interface of the filling head so as to introduce liquid carbon dioxide in the liquid carbon dioxide tank into the fracturing device main pipe; closing the output valve of the liquid carbon dioxide tank, and discharging out liquid carbon dioxide in the fracturing device main pipe; detaching the simple head, and mounting an energy release head and a bursting piece at the energy release of the fracturing device main pipe; and introducing liquid carbon dioxide in the liquid carbon dioxide tank into the fracturing device main pipe again, so as to finish the filling process of liquid carbon dioxide of the carbon dioxide fracturing device. The passive automatic-flow type filling method has the advantages that the operation is simple, safe and reliable, and the cost is low; the filling operation can be conveniently and rapidly finished without purchasing a special filling machine, so that the cost input can be substantially reduced; and the method has relatively good practicability.

Owner:北京正德天成科技发展有限公司 +4

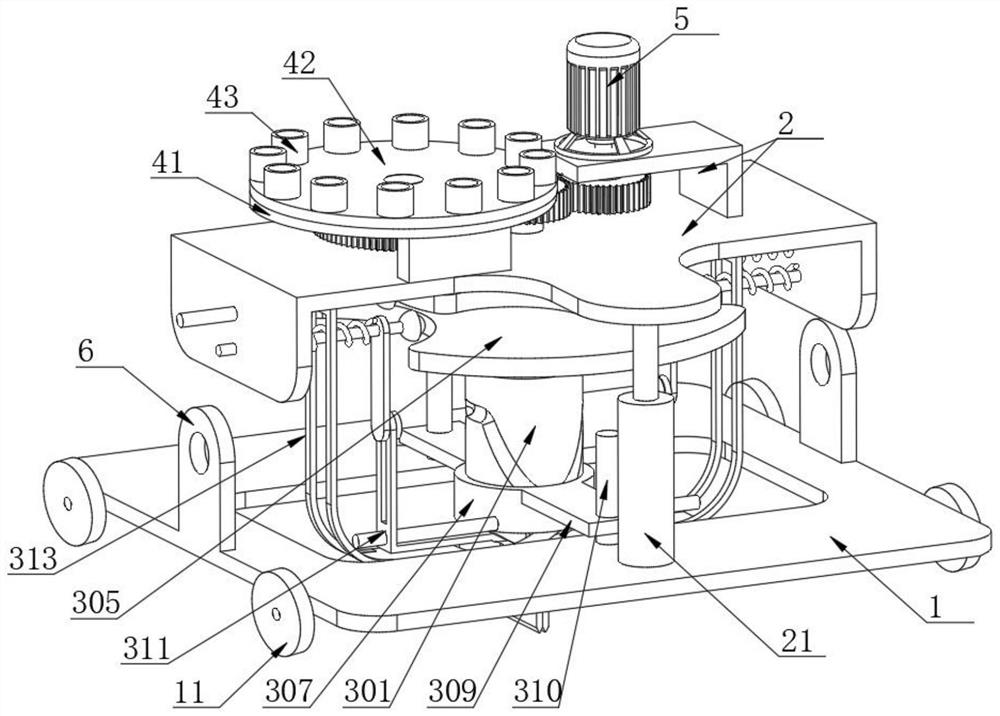

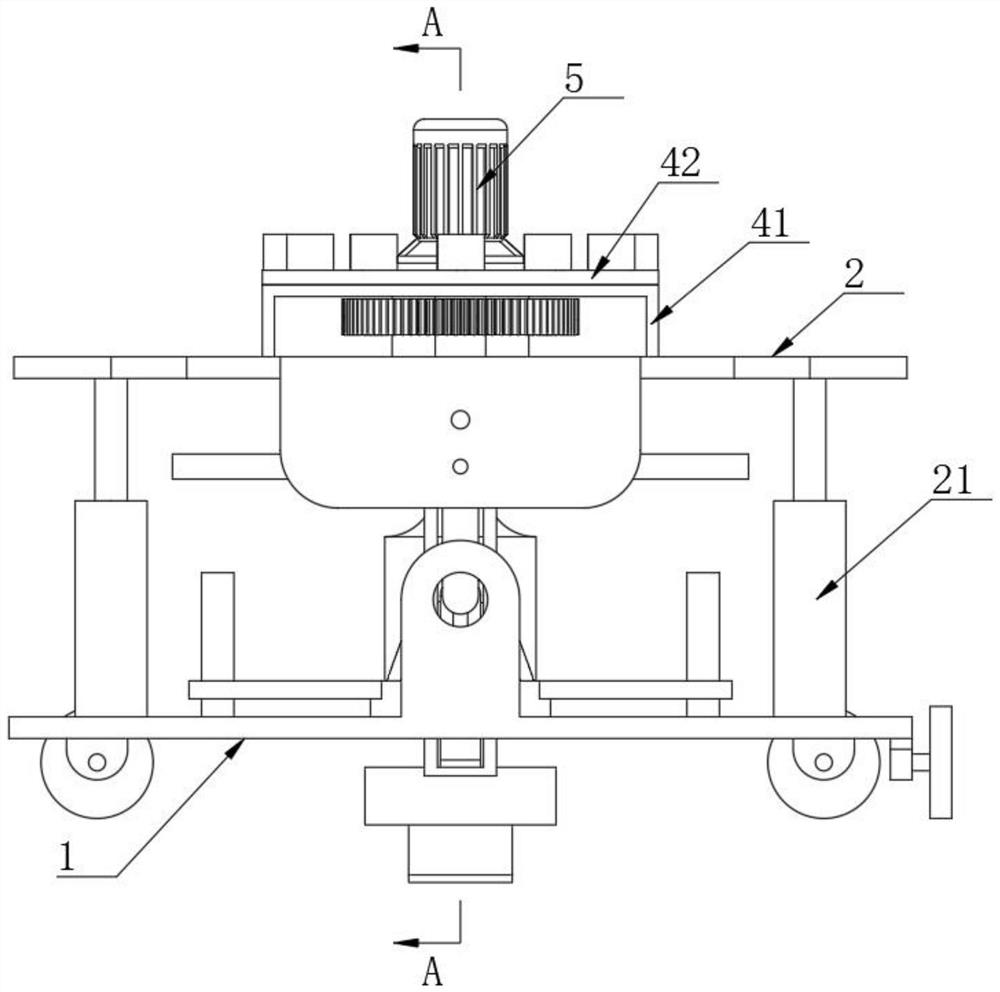

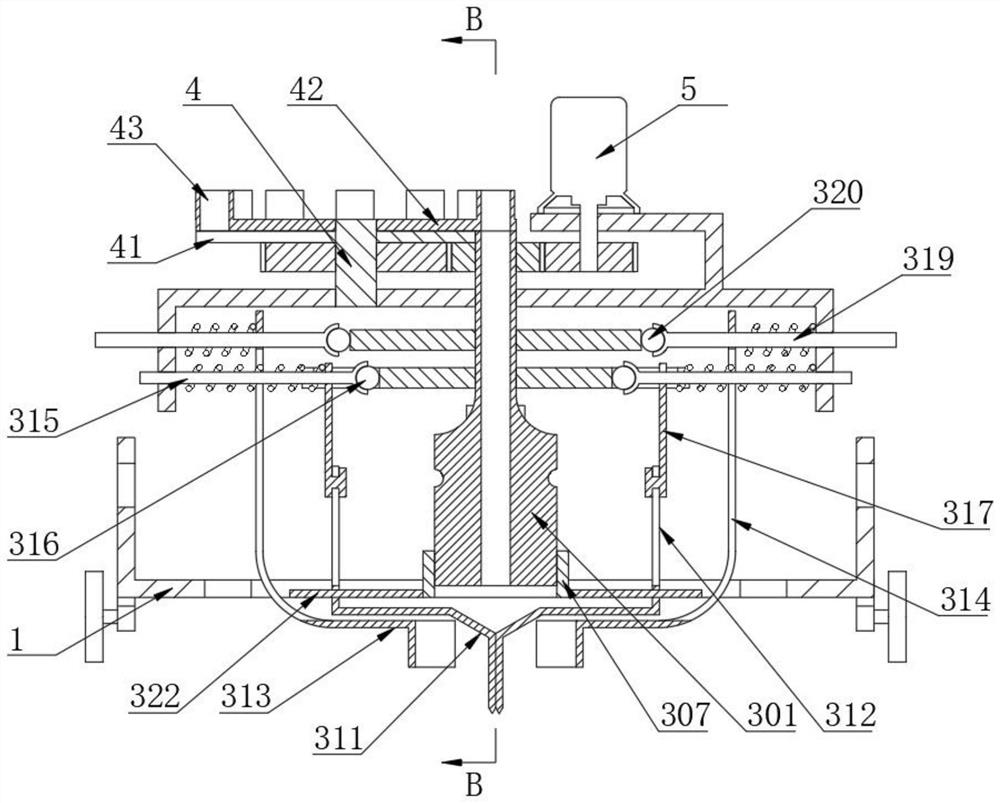

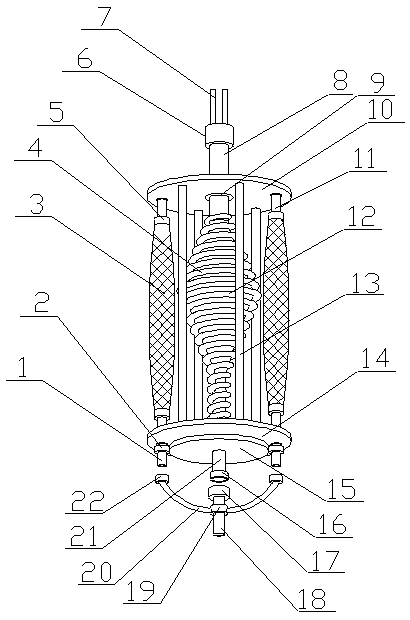

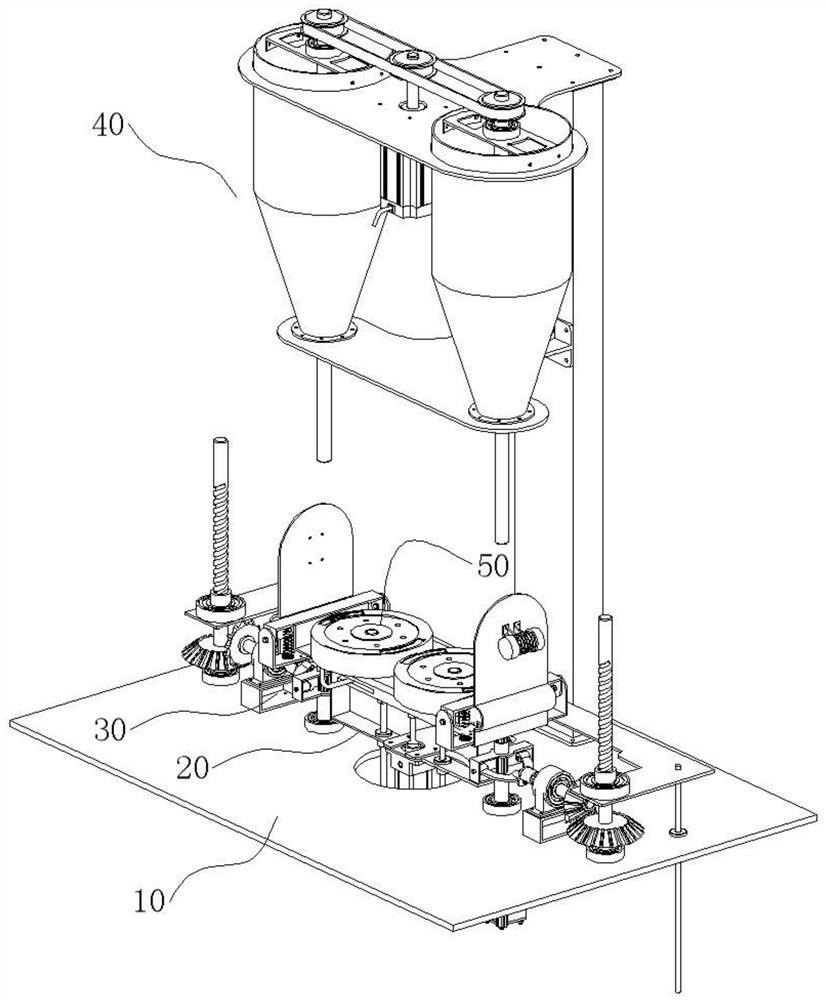

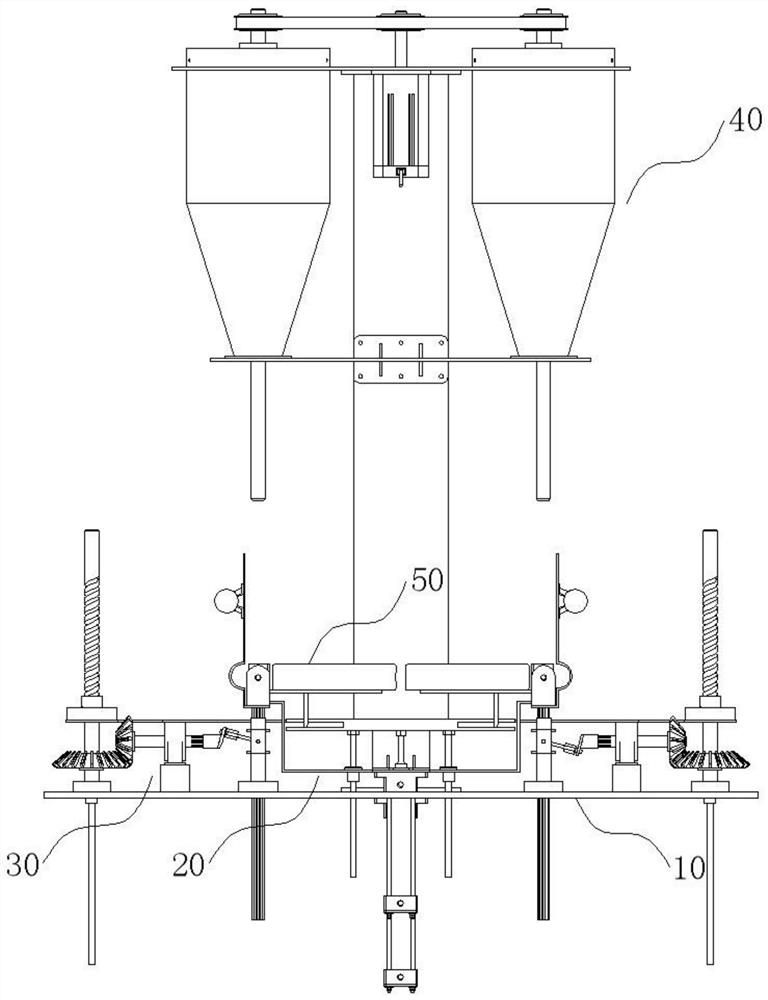

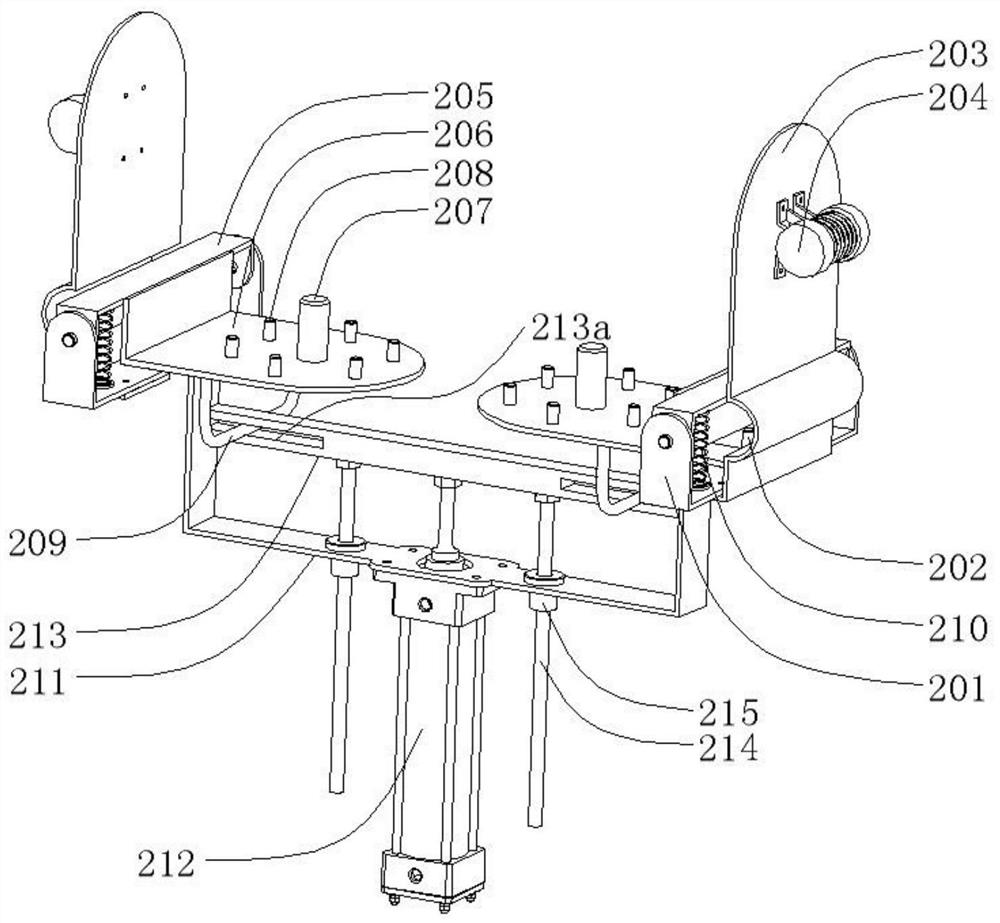

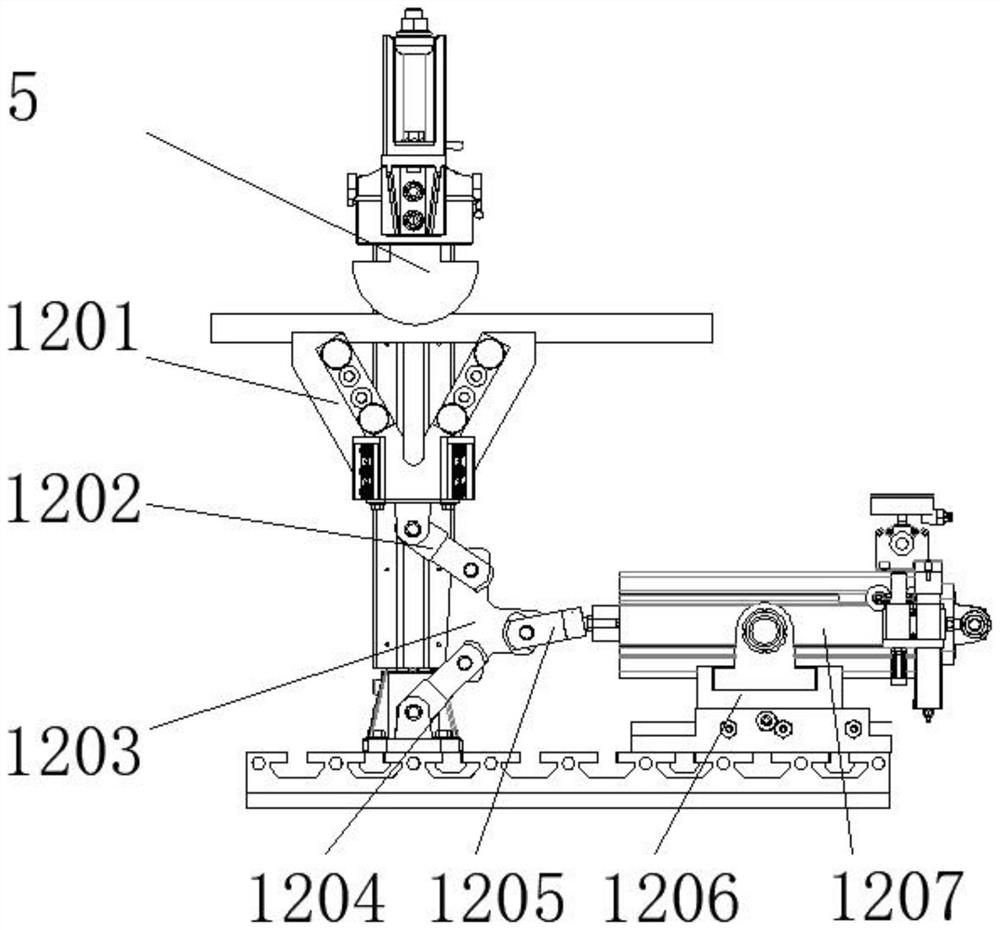

Automatic sand filling device for barbell discs

ActiveCN113697139AUnrestricted rotational freedomTo achieve the purpose of fillingDumb-bellsSolid materialHydraulic cylinderDrive shaft

The invention discloses an automatic sand filling device for barbell discs, and relates to the technical field of barbell disc production. The automatic sand filling device comprises a workbench, a clamping mechanism, a shaking mechanism and a sand filling mechanism; the clamping mechanism is arranged in the middle of the workbench and comprises a hinge strip, a positioning plate, a connecting strip, a first hydraulic cylinder and a lifting rod, and the clamping mechanism is used for automatically clamping shells of the barbell discs; the shaking mechanism is arranged beside the clamping mechanism and comprises a rectangular frame, a mounting shaft, a transmission shaft, a second hydraulic cylinder, a lifting plate and a lifting strip, and the shaking mechanism is used for automatically shaking the shells of the barbell discs; and the sand filling mechanism is arranged above the clamping mechanism and comprises a supporting pipe, a sand storage hopper, a conveying shaft and a conveying pipe, and the sand filling mechanism is used for automatically filling sand into the shells of the barbell discs. In conclusion, the automatic sand filling device for the barbell discs has the advantages of being ingenious in design, reasonable in structure, convenient to use, capable of saving labor force and high in sand filling efficiency.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

A jack-type ultra-deep tsv interconnected RF chip system-in-package process

ActiveCN110010484BTo achieve the purpose of fillingSolid-state devicesSemiconductor/solid-state device manufacturingEngineering physicsSystem in package

The invention discloses a jack-type ultra-deep TSV interconnected radio frequency chip system-level packaging process which comprises the steps of (101) the preliminary processing of a cover plate, (102) cover plate thinning processing, (103) intermediate layer processing, (104) base processing, and (105) packaging. The present invention provides the jack-type ultra-deep TSV interconnected radio frequency chip system-level packaging process with ultra-deep TSV hole filling.

Owner:浙江集迈科微电子有限公司

A food processing oyster sauce filling head

The invention discloses a food processing type oyster sauce filling head, and particularly discloses a filling head device. The filling head device has the advantages that after oyster sauce is heated, blockages on a filtering screen cylinder can be washed out through the rotation of the filter screen cylinder, and the filter screen cylinder can be prevented from being blocked. The filling head ischaracterized in that a main fixing plate is arranged right above an auxiliary fixing plate and is connected to the auxiliary fixing plate through a plurality of connecting rods; the distance betweenevery two adjacent connecting rods is equal; the main fixing plate and the auxiliary fixing plate are of circular-plate-shaped structures and are equal in size; a heating cylinder is arranged betweenthe main fixing plate and the auxiliary fixing plate; the two ends of the heating cylinder are arranged in the middle of the main fixing plate and the middle of the auxiliary fixing plate through supporting bearings separately; the heating cylinder is spindle-shaped and is made of copper; a spiral blade is arranged on the heating cylinder and is made of copper; a plurality of grooves are formed in the surface of the spiral blade; one end of a hollow rotating rod is connected to one end of the heating cylinder; a connecting sleeve sleeves the other end of the hollow rotating rod; and a heatingpipe is arranged in the heating cylinder and is spirally distributed.

Owner:徐州果姿电子商务有限公司

An automatic sand tank device for barbell plates

ActiveCN113697139BUnrestricted rotational freedomTo achieve the purpose of fillingDumb-bellsSolid materialHydraulic cylinderDrive shaft

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

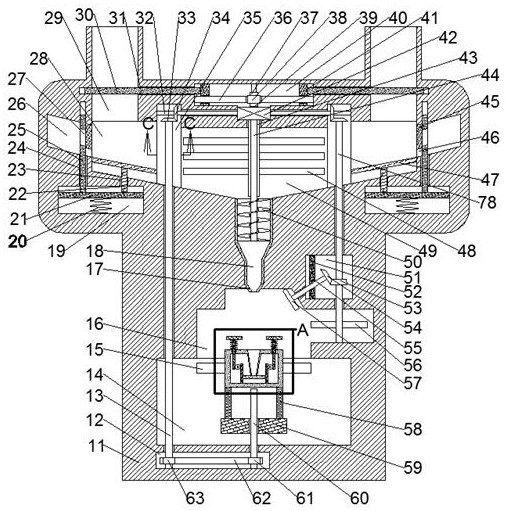

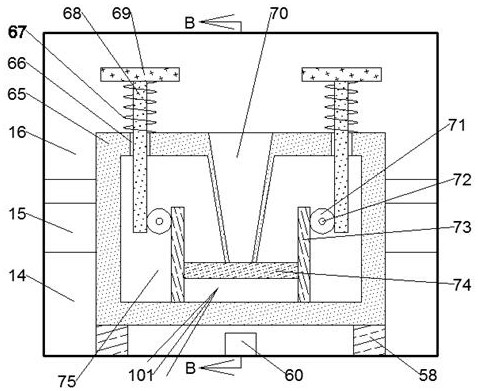

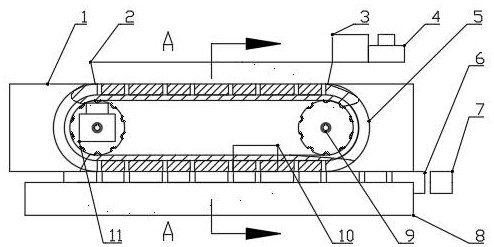

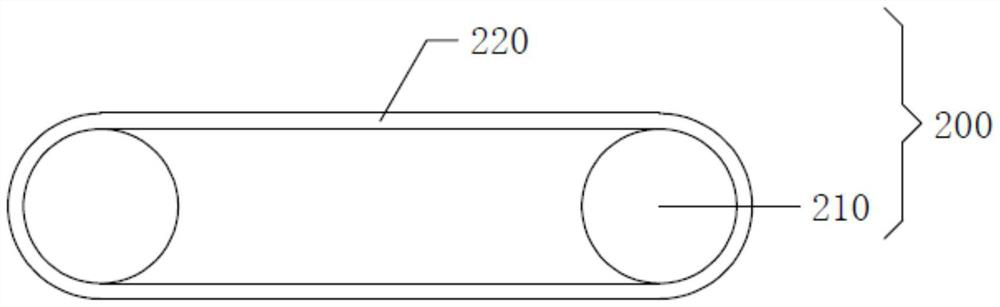

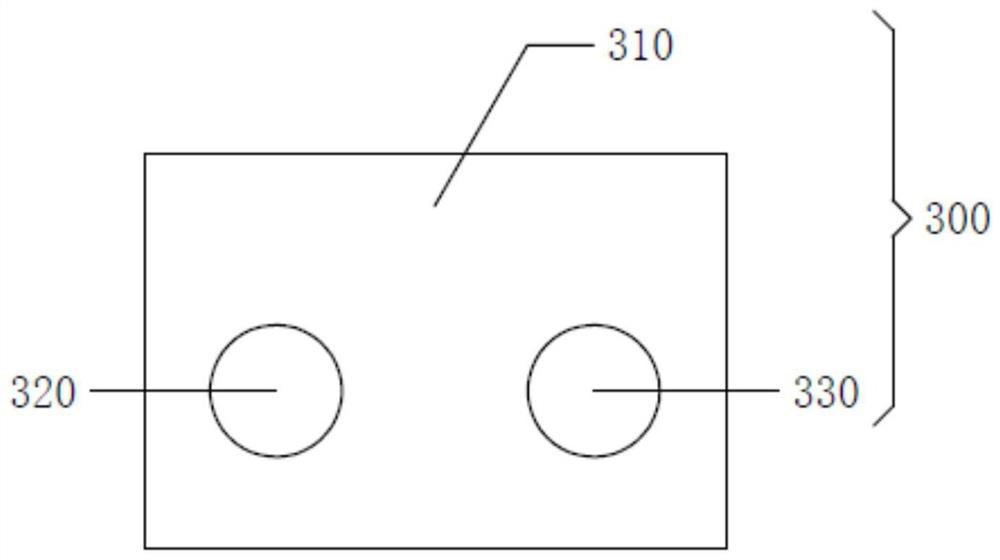

Powder cavity filling device

InactiveCN112607072ATo achieve the purpose of fillingStable working speedLarge containersSolid materialTransmission beltElectric machinery

A powder cavity filling device comprises a filling device body and a conveying device. A mounting groove is formed in the side face of a sealing block, the outer wall of a conveying belt makes contact with the groove wall of the mounting groove, belt wheels are arranged at the two ends of the inner wall of the conveying belt correspondingly, the belt wheels are matched with the inner wall of the conveying belt, and a motor B is installed on the side face of one belt wheel. A plurality of cavity holes are formed in the outer wall of the conveying belt at even intervals, the bottom of a trough is matched with an opening in the top of the sealing block, a motor A and a vibration device are installed at the top of the sealing block, the conveying device comprises a base, and the base is arranged at the bottom of the sealing block. A plurality of bars which are uniformly arranged at intervals and move at a constant speed are arranged on the top surface of the base. According to the powder cavity filling device, the problems of many defects of a conventional filling device are solved.

Owner:XIHUA UNIV

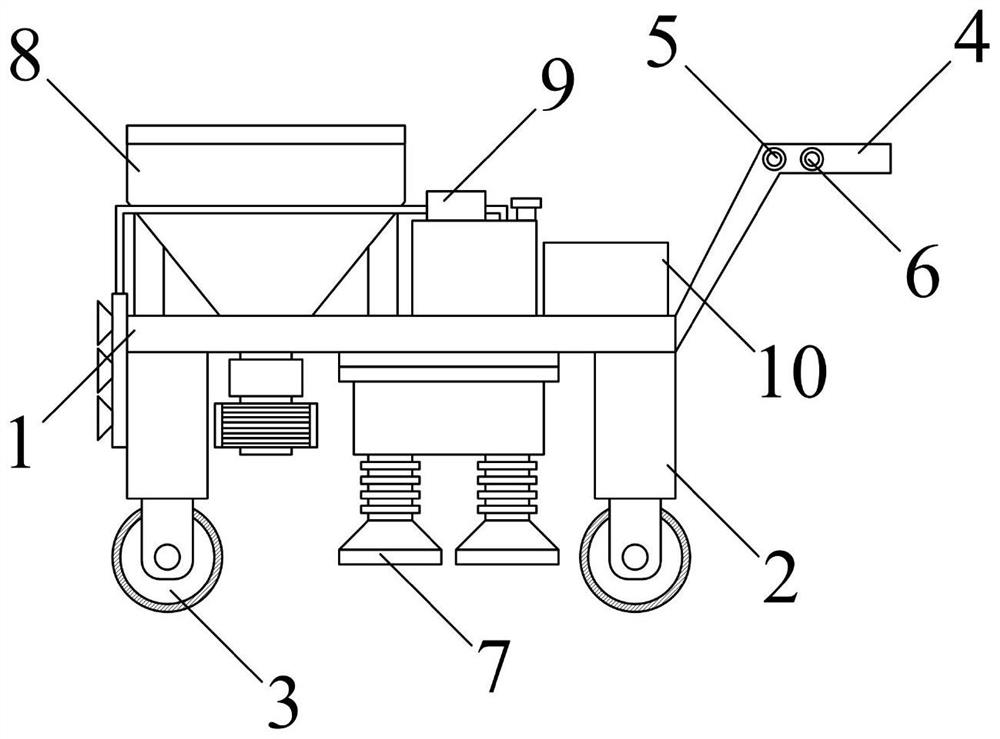

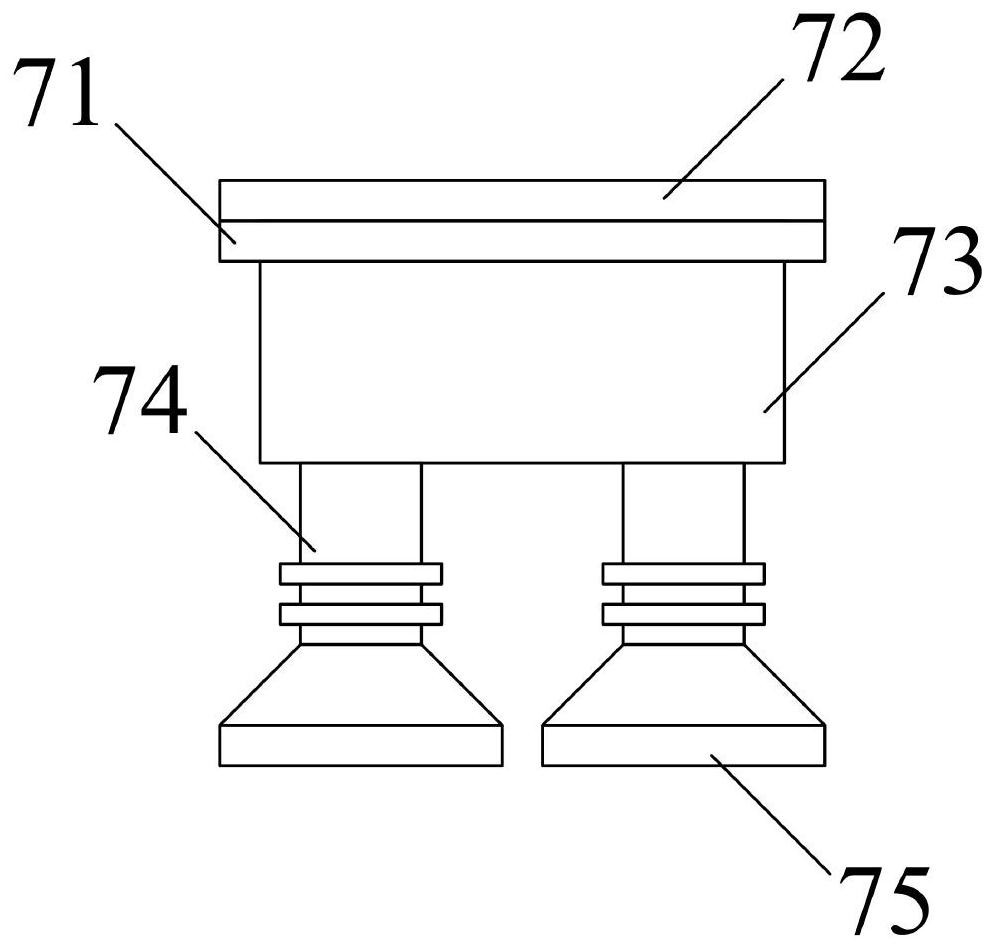

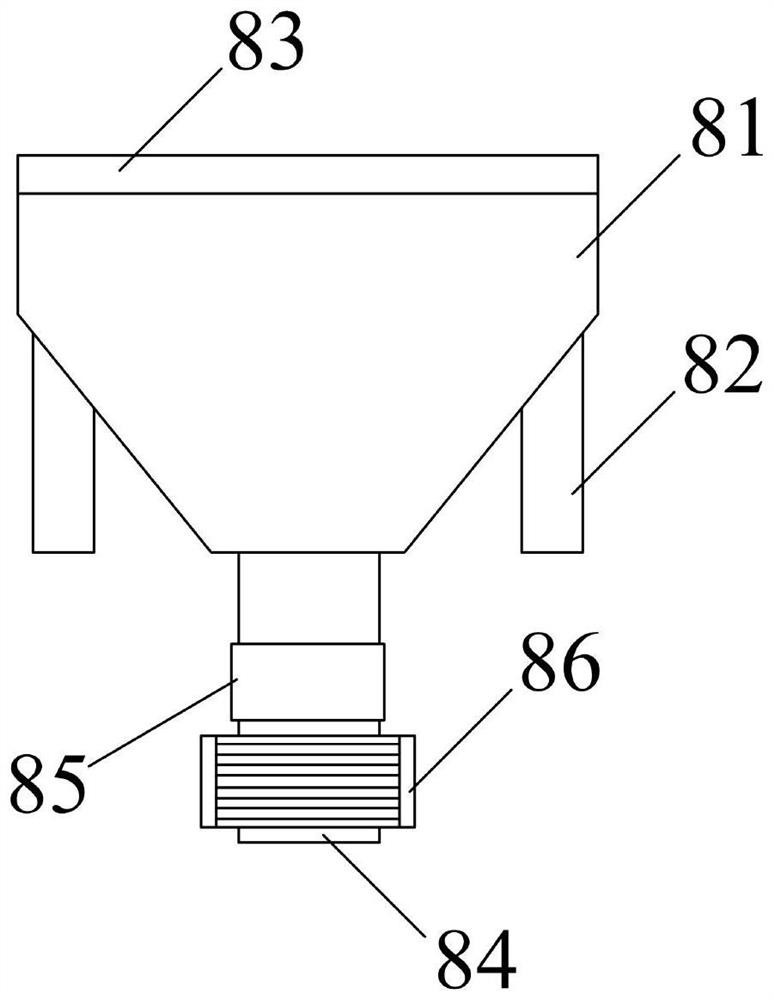

Anchoring ditch tamping device with filling function

PendingCN112301997AImprove work efficiencyReduce labor costsUsing liquid separation agentNon-rotating vibration suppressionStructural engineeringElectric control

The invention discloses an anchoring ditch tamping device with a filling function. The anchoring ditch tamping device comprises a support plate, a support rod, universal wheels, a push handle, a tamping assembly, a filling assembly, a dust falling assembly and an electric control cabinet. According to the anchoring ditch tamping device, the filling assembly is arranged, an electromagnetic valve iscontrolled to power on and operate through a first button switch during use, and materials in a filling box fall into an anchoring ditch through a discharging pipe, so that the purpose of filling isachieved; the filling assembly is integrated on the tamping device, so that the equipment utilization rate is increased, the working efficiency of the tamping device is improved, and the labor cost ofthe tamping device is reduced; and the dust falling assembly is arranged, a booster pump is controlled to power on and operate through a second button switch, and water in a water tank is conveyed toa liquid conveying pipe by the booster pump and is atomized and sprayed on a work site through an atomization spray head, so that the phenomenon of dust raising during tamping is avoided, and the damage to the body health of operating personnel is prevented.

Owner:广州市第三市政工程有限公司

A passive self-flowing filling method for a carbon dioxide cracking device

ActiveCN107304675BEasy to operateLow costDisloding machinesContainer filling methodsProcess engineeringLiquid carbon

The invention discloses a passive automatic-flow type filling method of a carbon dioxide fracturing device. The method comprises the following steps: rotatably mounting a filling head on a filling end of a fracturing device main pipe, and rotatably mounting a simple head to an energy release end of the fracturing device main pipe; connecting an output valve of a liquid carbon dioxide tank with a filling interface of the filling head so as to introduce liquid carbon dioxide in the liquid carbon dioxide tank into the fracturing device main pipe; closing the output valve of the liquid carbon dioxide tank, and discharging out liquid carbon dioxide in the fracturing device main pipe; detaching the simple head, and mounting an energy release head and a bursting piece at the energy release of the fracturing device main pipe; and introducing liquid carbon dioxide in the liquid carbon dioxide tank into the fracturing device main pipe again, so as to finish the filling process of liquid carbon dioxide of the carbon dioxide fracturing device. The passive automatic-flow type filling method has the advantages that the operation is simple, safe and reliable, and the cost is low; the filling operation can be conveniently and rapidly finished without purchasing a special filling machine, so that the cost input can be substantially reduced; and the method has relatively good practicability.

Owner:北京正德天成科技发展有限公司 +4

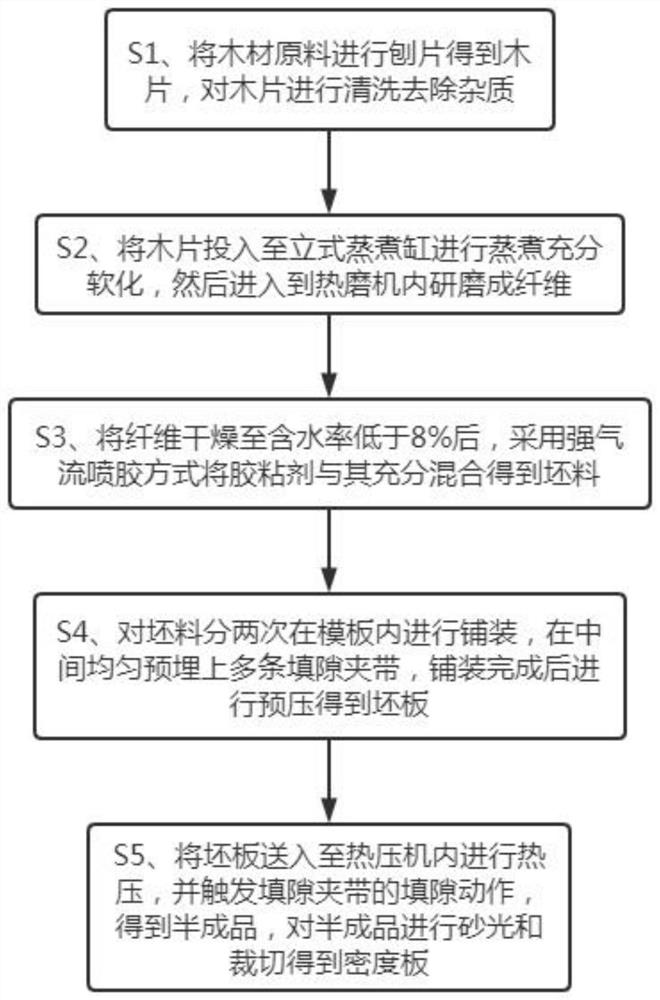

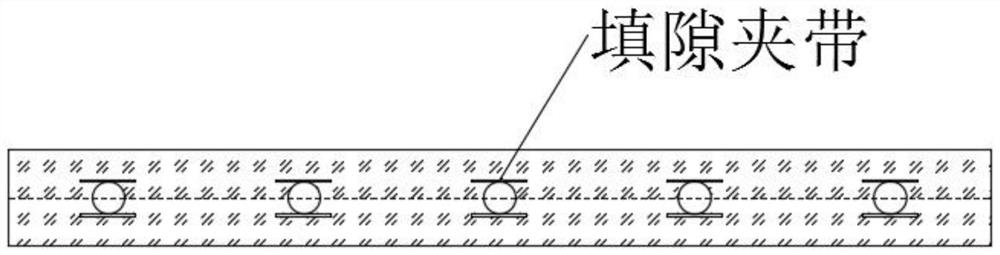

Production method of environment-friendly density board

ActiveCN114571571AHigh strengthReduce porositySolid waste managementDomestic articlesThermodynamicsMicrosphere

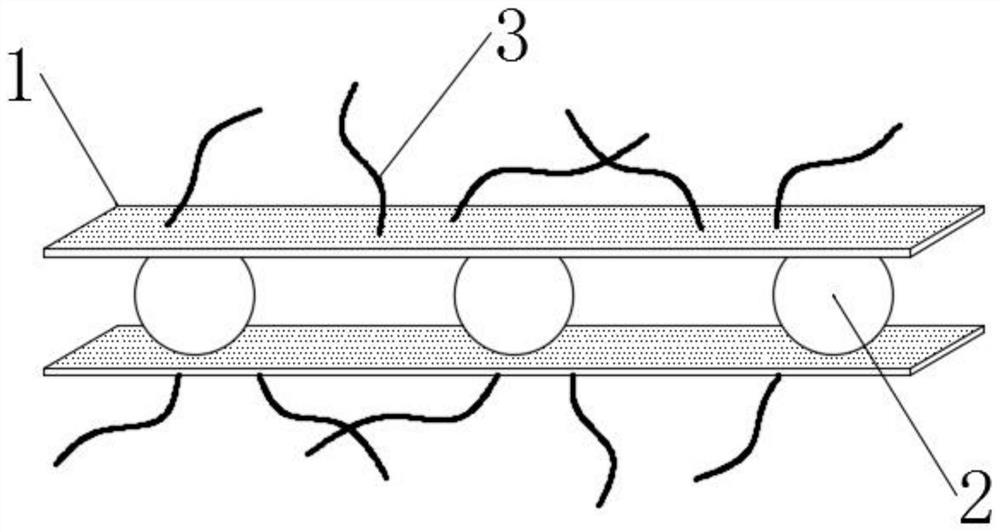

The invention discloses a production method of an environment-friendly density board, belongs to the technical field of density board production, and can realize that in the production process of the density board, a plurality of uniformly distributed gap filling entrainments are pre-buried in a paving process, and then a pre-pressing process is carried out, so that the combination effect between the gap filling entrainments and the density board is improved; and in the final hot pressing process, the gap filling action of gap filling entrainment is triggered, specifically, the gap filling microspheres are melted under the action of high temperature and carry powder to flow and fill existing pores under the extrusion action, the purpose of eliminating the pores is achieved, and the residual gap filling microspheres can be reserved in the density board to achieve the effect of improving the strength. Compared with an existing density board, the porosity of the density board produced through the method is obviously reduced, density distribution is more uniform, and the mechanical strength is obviously improved.

Owner:江苏苏林木业有限公司

U-shaped lamp tube manufacturing and processing equipment

PendingCN112499948AReasonable structureEasy to sendGlass reforming apparatusRotational axisStraight tube

The invention discloses a U-shaped lamp tube manufacturing and machining equipment, which comprises a chemical box, a bending box, a first rack and a machine body, the first rack is arranged on one side of the bending box, the machine body is placed at the bottom of one side of the interior of the bending box, and a control panel is fixedly installed at one end of the exterior of the bending box through screws; a plurality of flamethrowers are fixedly installed in the center of the top of the first rack through supporting rods, a rotating shaft is movably connected to the first rack through abearing, conveying wheels are fixedly installed on the rotating shaft, and the number of the conveying wheels on the first rack is four. A cylinder is arranged to drive a third connecting rod, the third connecting rod can drive a connecting block, the connecting block can drive a first connecting rod to move, the first connecting rod can drive the bending block, the straight pipe can be bent intoa U shape under the action of a bending head, and therefore the purpose of convenient bending is achieved.

Owner:天津市泰恒盛机电设备工程有限公司

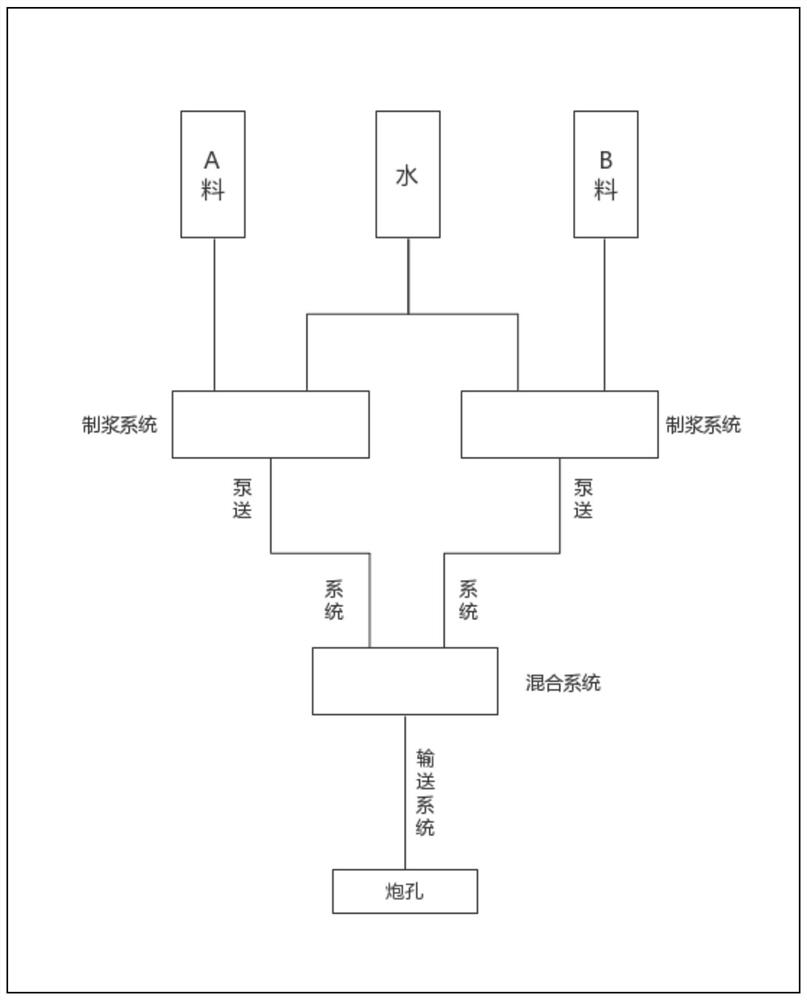

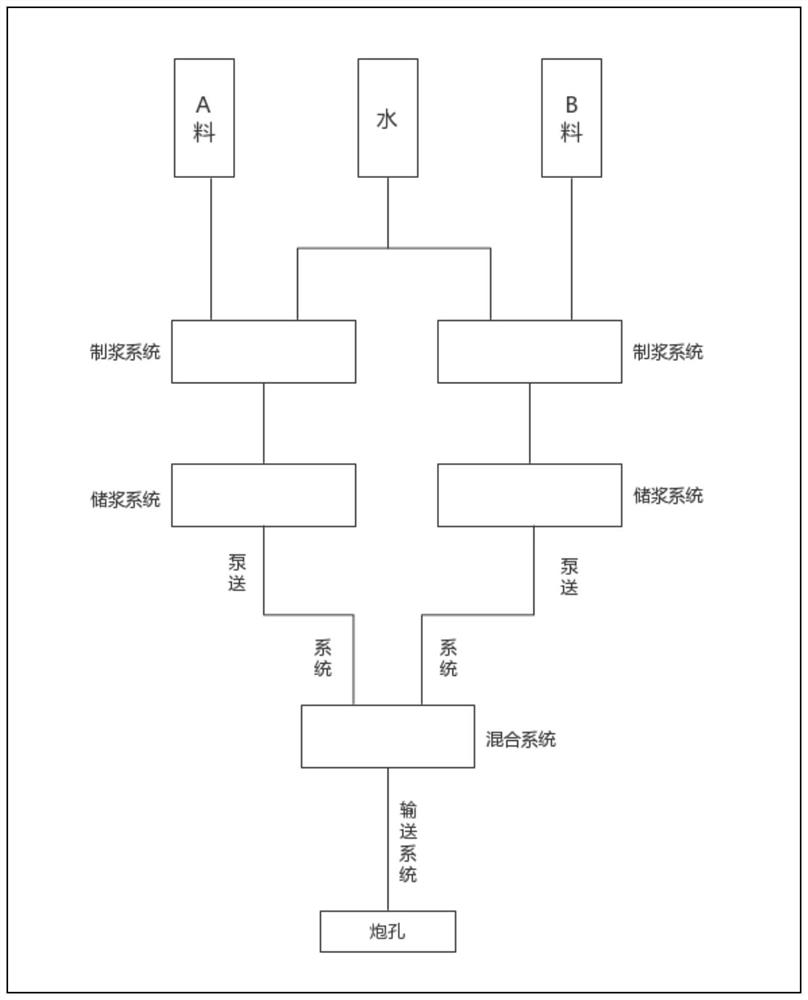

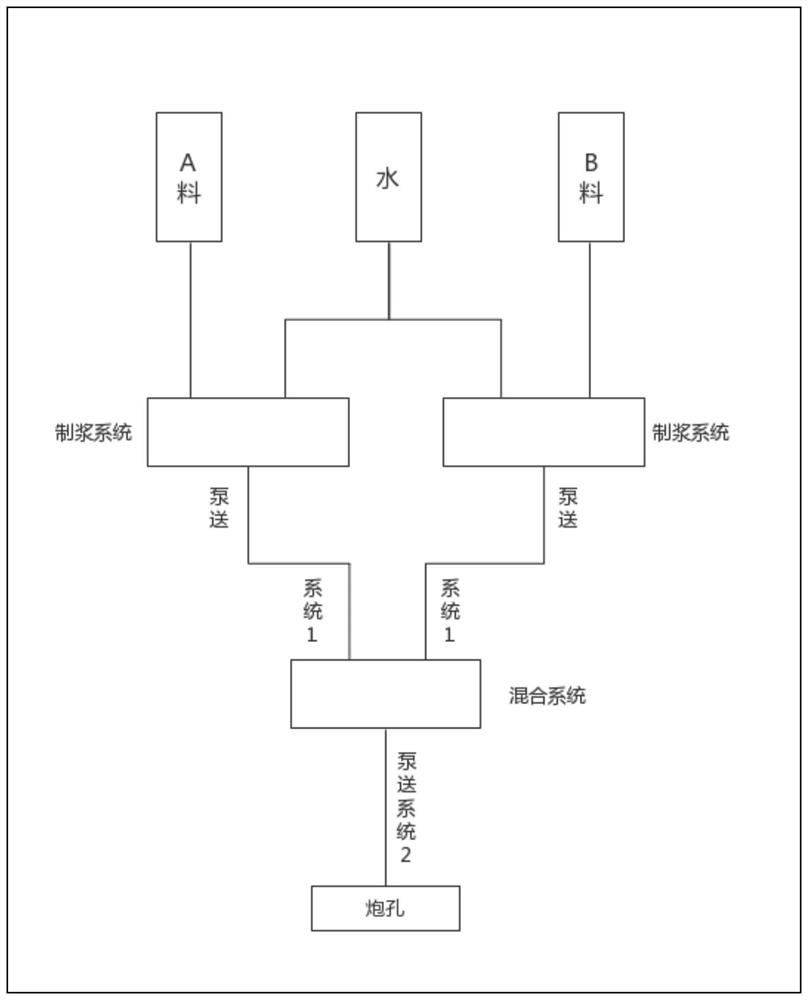

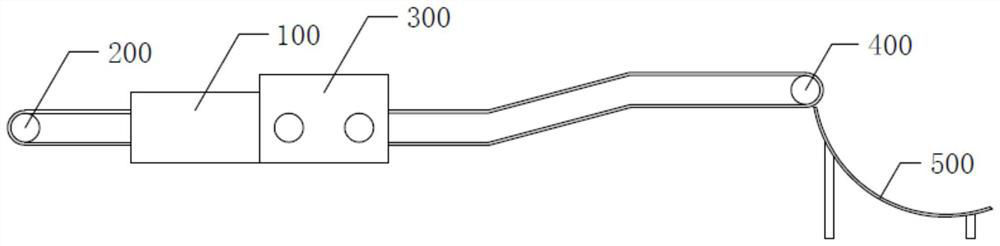

Blasting blast hole mechanical filling construction process method using quick-setting stemming

PendingCN114777591ATo achieve the purpose of fillingTo achieve the blocking effectBlastingConstruction engineeringSlurry

The invention discloses a blasting hole mechanical filling construction process method using quick-setting stemming, and relates to the technical field of engineering blasting. The method comprises the following steps: in a construction process, a quick-setting stemming material is used as a blasting hole filling material, the quick-setting stemming material and water are prepared into quick-setting stemming slurry with the mass ratio of the material to the water being 1: (1-3), the quick-setting stemming slurry is conveyed into a blast hole through a pipeline in a pumping manner, and the quick-setting stemming slurry is quickly set into solid stemming, so that a good blocking effect is achieved. The quick-setting stemming material is composed of a basic material A and a basic material B, the device is applied to a blasting operation construction scene, has the same filling effect and effect as manual stemming filling, can be pumped to achieve blasting operation blast hole filling mechanical operation, and is beneficial to improving the automatic operation level and the blasting effect of blasting operation.

Owner:北京中大科技发展有限公司

Gangue non-lifting filling belt conveyor

InactiveCN111810231ATo achieve the purpose of fillingSimple structureMaterial fill-upUnderground transportProcess engineeringCoal

The invention discloses a gangue non-lifting filling belt conveyor in the technical field of gangue landfill. The gangue non-lifting filling belt conveyor comprises a storage bin, a coal falling conveyor belt, a belt conveyor, a filling belt and a sliding shoe assembly, wherein the coal falling conveyor belt is arranged on the left side surface of the storage bin, and the right end of the coal falling conveyor belt is inserted into an inner cavity of the storage bin; the belt conveyor is installed on the right side surface of the storage bin, and an inner cavity of the belt conveyor communicates with the inner cavity of the storage bin; the filling belt is installed on the right side surface of the belt conveyor and penetrates through the belt conveyor to be inserted into the inner cavityof the storage bin; and the sliding shoe assembly is arranged on the right side of the bottom of the filling belt. The gangue non-lifting filling belt conveyor is simple in structure and low in cost.An original equipment operation mode is changed, and the original equipment performance and assembling mode is changed through re-assembling, so that the purpose of gangue filling is achieved.

Owner:LONGKOU MINING GRP

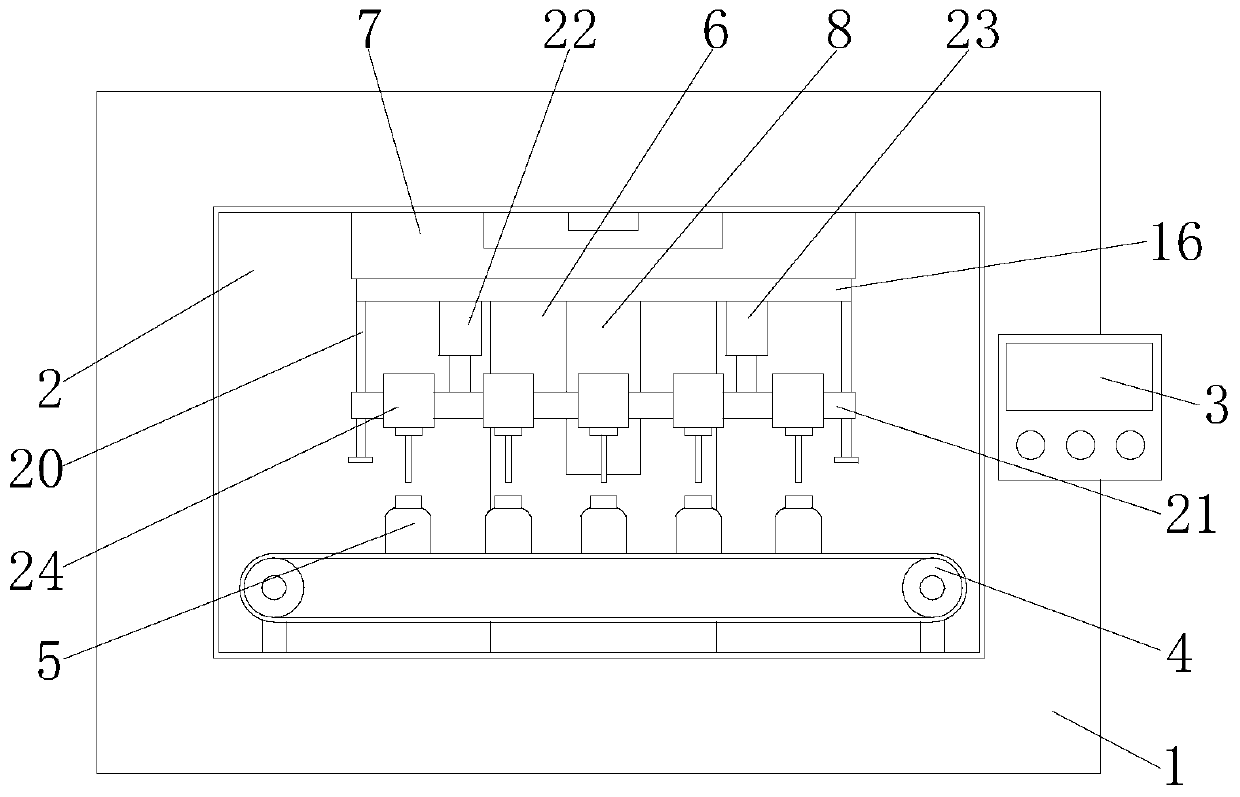

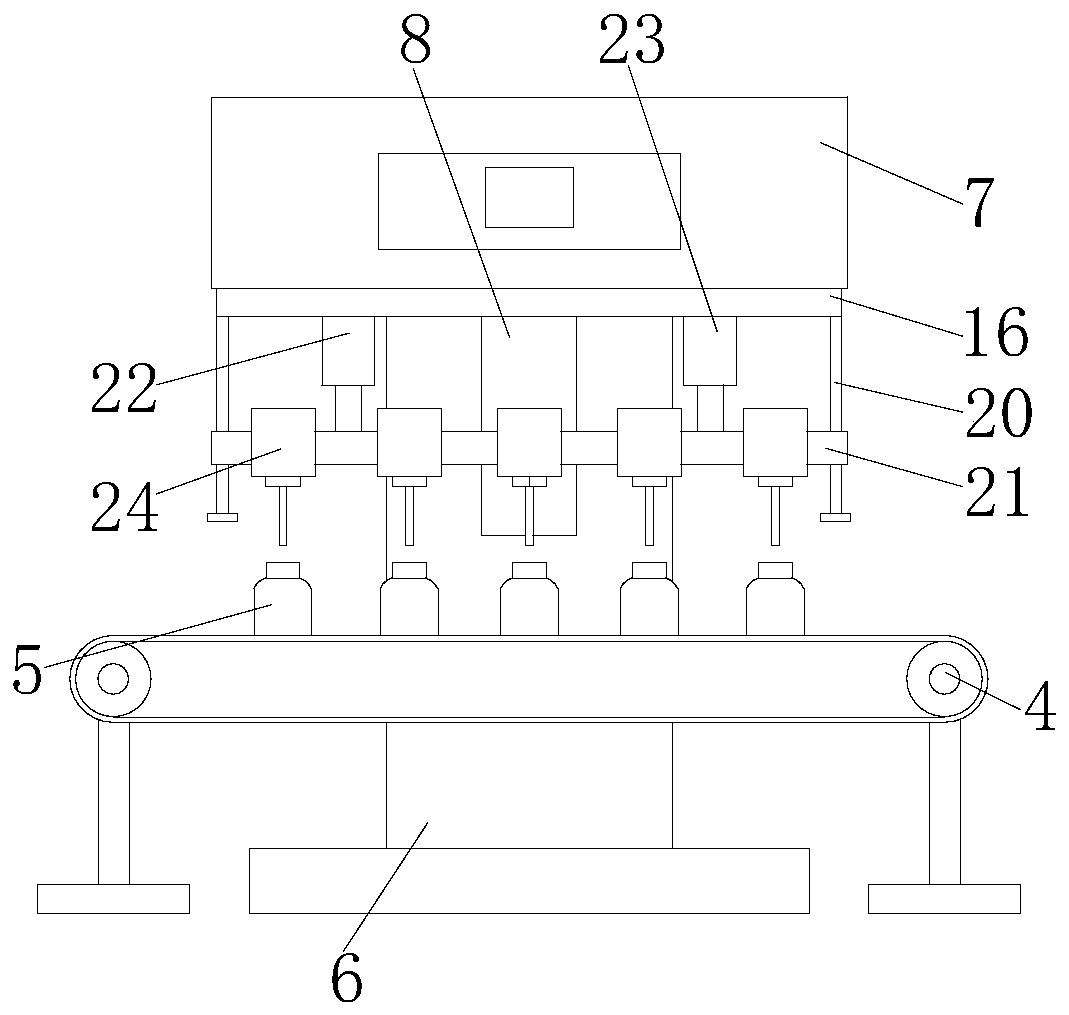

High-efficiency dairy product filling machine

InactiveCN110127580AImprove stabilityFast filling speedSafety device in filling machineryMotor driveShortest distance

The invention discloses a high-efficiency dairy product filling machine which comprises a box body. An observation mirror is fixedly connected to the front side of the box body, and a control screen is fixedly connected to the right side of the front side of the box body. By arranging a motor, a roller, a slide block, a fixed bar, an electric telescopic rod and a supporting mechanism matched in use, the motor drives the filling machine to move at short distances on the front and back sides, the motor is matched with the electric telescopic rod in use to fill two rows of bottle bodies quickly,and the slide block drives the roller to move in an inner cavity of a chute, so that the operating stability of the filling machine is improved. By means of the supporting mechanism, a supporting rolefor movement of a spray head on the front and back sides can be played, so that the bearing capacity is improved. The high-efficiency dairy product filling machine solves the problem that an existingsingle line filling machine only can fill one row of bottle bodies, and is many in pause number of times of a conveyor belt, quick to consume energy and low in filling efficiency. The high-efficiencydairy product filling machine has the advantages of filling in double rows and being high in filling speed, and is worth being popularized.

Owner:灵璧县童师傅食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com