Rounding encrusting machine

A stuffing machine and frame technology, applied in baking, dough forming and cutting equipment, dough processing, etc., can solve the problem of not being able to meet the requirements of glutinous rice balls, so as to shorten working time, improve working efficiency and save working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

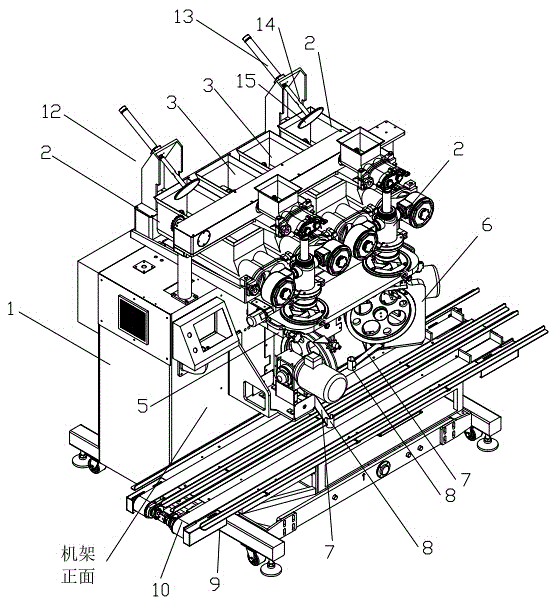

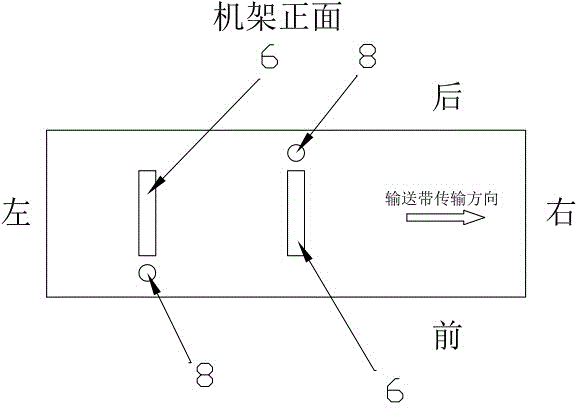

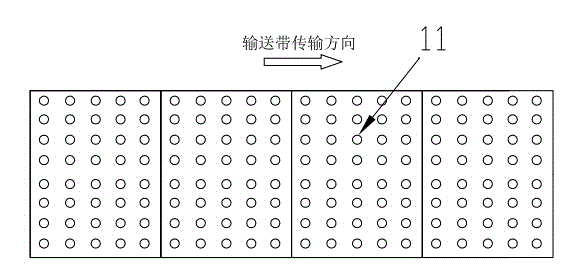

[0037] A kind of round stuffing machine includes a frame 1 and a stuffing device 2 arranged on the frame 1, a dough supply device 3, at least two compound head devices 4, a cutter device 5 and a round device 6, each compound The head device 4 communicates with a stuffing device 2 and a noodle supply device 3 respectively, and a cutter device 5 is arranged below each compound head, and a rounding device 6 is arranged below the cutting device 5; the rounding device 6 The bottom is connected to the drop hopper 8 through the transmission channel 7, and a conveying device 9 is arranged below the falling hopper 8, and a conveyor belt 10 is arranged on the conveying device 9, and a driving conveyor belt 10 is arranged on the conveying device 9 for intermittent transmission. The moving driving mechanism and the driving mechanism that drives the conveyor belt as a whole to move close to and away from the frame 1; . The staggered arrangement specifically means that the projection of th...

Embodiment 2

[0041] A kind of round stuffing machine includes a frame 1 and a stuffing device 2 arranged on the frame 1, a dough supply device 3, at least two compound head devices 4, a cutter device 5 and a round device 6, each compound The head device 4 communicates with a stuffing device 2 and a noodle supply device 3 respectively, and a cutter device 5 is arranged below each compound head, and a rounding device 6 is arranged below the cutting device 5; the rounding device 6 The bottom is connected to the drop hopper 8 through the transmission channel 7, and a conveying device 9 is arranged below the falling hopper 8, and a conveyor belt 10 is arranged on the conveying device 9, and a driving conveyor belt 10 is arranged on the conveying device 9 for intermittent transmission. The moving driving mechanism and the driving mechanism that drives the conveyor belt as a whole to move close to and away from the frame 1; . The staggered arrangement specifically means that the projection of th...

Embodiment 3

[0046] A kind of round stuffing machine includes a frame 1 and a stuffing device 2 arranged on the frame 1, a dough supply device 3, at least two compound head devices 4, a cutter device 5 and a round device 6, each compound The head device 4 communicates with a stuffing device 2 and a noodle supply device 3 respectively, and a cutter device 5 is arranged below each compound head, and a rounding device 6 is arranged below the cutting device 5; the rounding device 6 The bottom is connected to the drop hopper 8 through the transmission channel 7, and a conveying device 9 is arranged below the falling hopper 8, and a conveyor belt 10 is arranged on the conveying device 9, and a driving conveyor belt 10 is arranged on the conveying device 9 for intermittent transmission. The moving driving mechanism and the driving mechanism that drives the conveyor belt as a whole to move close to and away from the frame 1; . The staggered arrangement specifically means that the projection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com