Blasting blast hole mechanical filling construction process method using quick-setting stemming

A construction technique and quick-setting technology, applied in blasting and other directions, can solve problems such as inability to realize mechanized operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

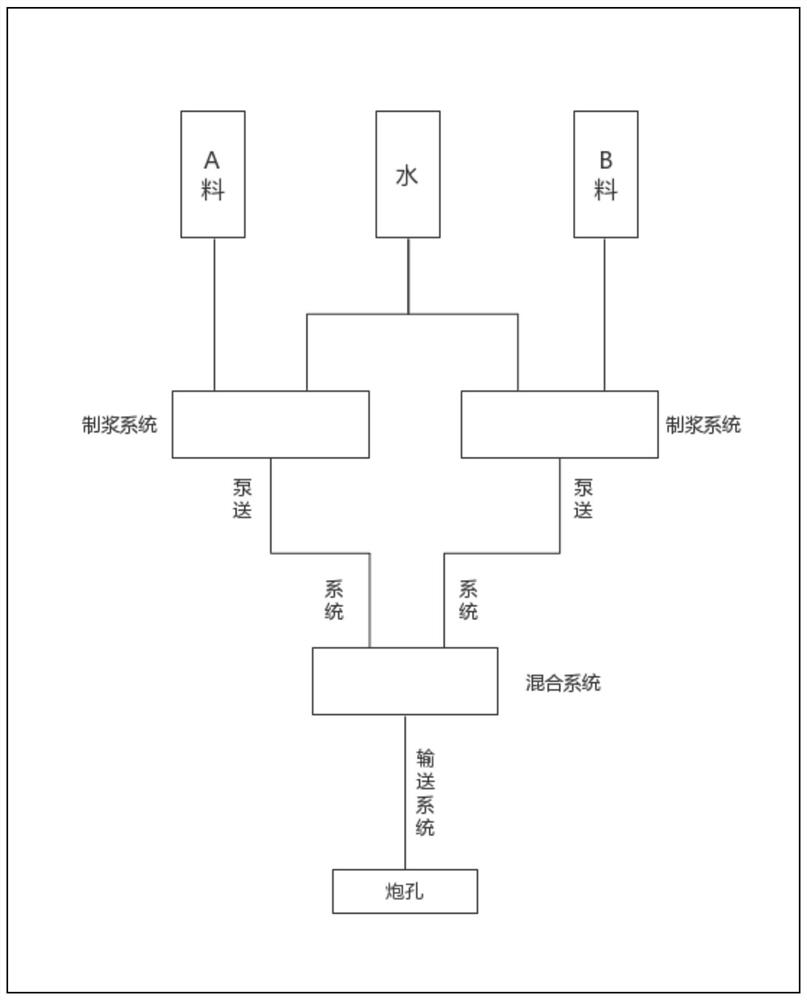

[0025] like figure 1 As shown in the figure, prepare the water for preparation, and quantitatively introduce the water into the two slurry mixing tanks according to the demand through the water pump, flow meter and three-way valve, and pass the two kinds of quick-setting mud base materials A and B through the quantitative feeding device. According to the required amount, it is quantitatively introduced into two pulping mixing tanks, and the two basic materials A and B are mixed with water through mechanical stirring to prepare two kinds of slurries with a material-to-water mass ratio of 1:(1-3).

[0026] Two sets of mud plunger pumps of the pumping system are used to pump out the A slurry and the B slurry in the slurry mixing tank for transportation. The volume ratio of the two is 1:1. It is fully mixed in the mixer to form a quick-setting blasting mud slurry for filling the blasting holes. The mixed rapid-setting blasting mud slurry enters the filling pipeline, and is transpo...

Embodiment 2

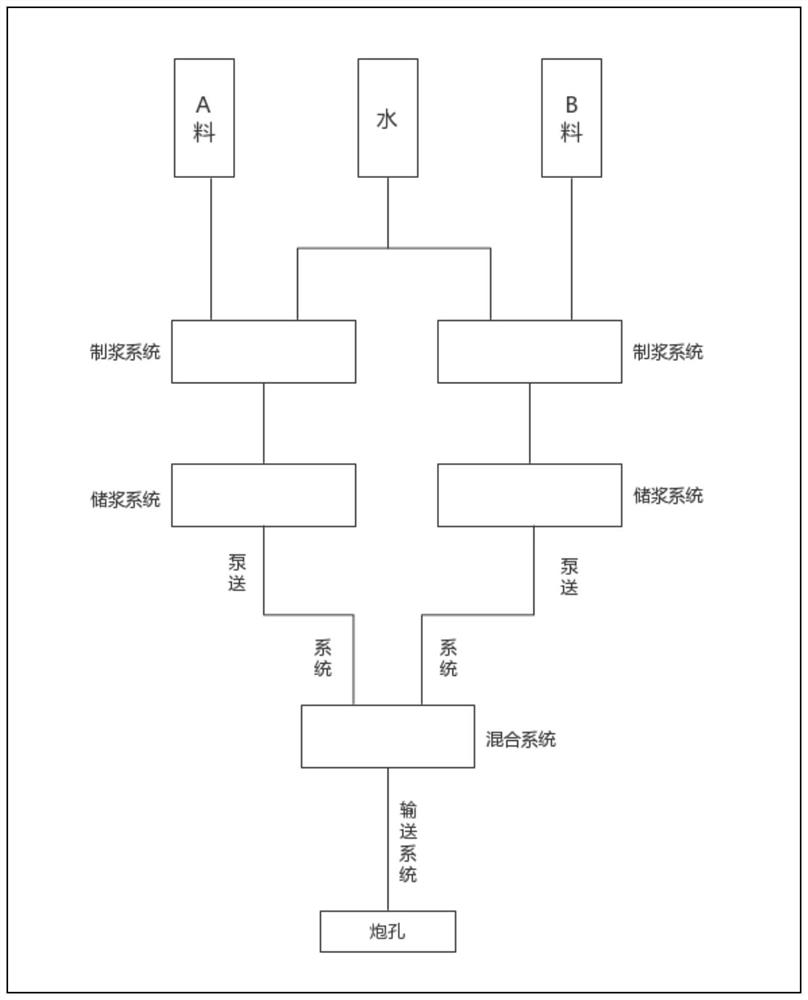

[0028] like figure 2 As shown in the figure, prepare the water for preparation, and quantitatively introduce the water into the two slurry mixing tanks according to the demand through the water pump, flow meter and three-way valve, and pass the two kinds of quick-setting mud base materials A and B through the quantitative feeding device. According to the required amount, it is quantitatively introduced into two pulping mixing tanks, and the two basic materials A and B are mixed with water through mechanical stirring to prepare two kinds of slurries with a material-to-water mass ratio of 1:(1-3). The A slurry and the B slurry are transferred to two slurry storage tanks by means of pump or self-flow and transported to the construction site for use.

[0029] When the blast hole needs to be filled, the slurry A and B in the slurry tank are pumped out respectively by the slurry plunger pumps of two pumping systems for transportation. The volume ratio of the two transportation is 1...

Embodiment 3

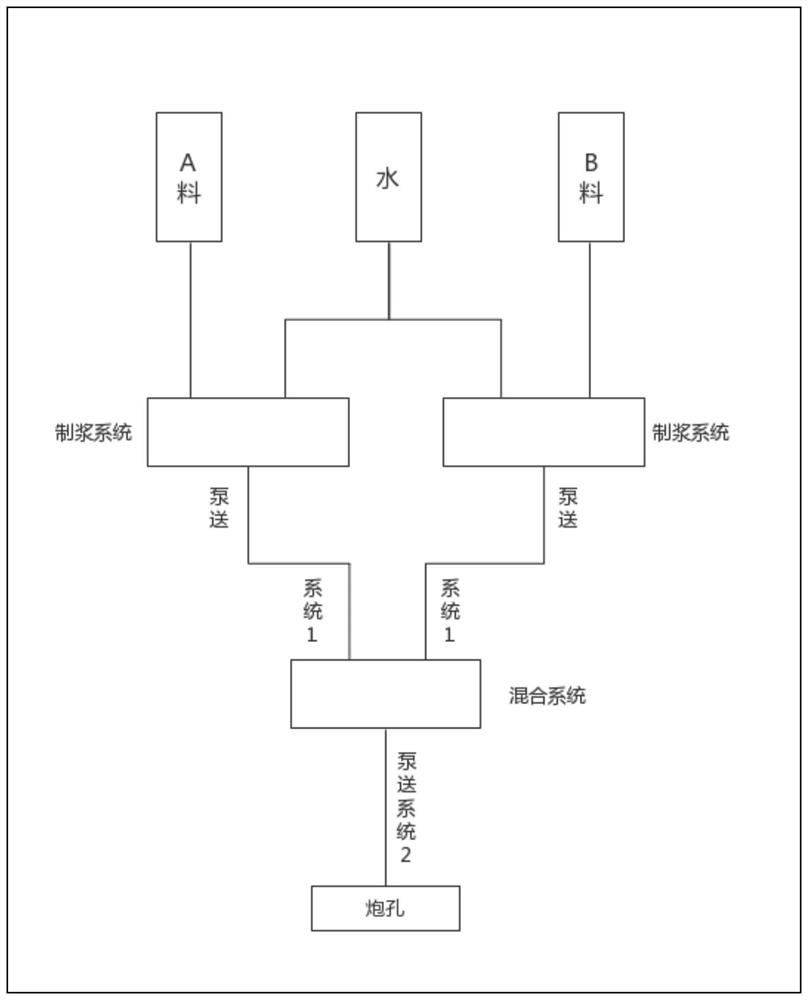

[0031] like image 3 As shown in the figure, prepare the water for preparation, and quantitatively introduce the water into the two slurry mixing tanks according to the demand through the water pump, flow meter and three-way valve, and pass the two kinds of quick-setting mud base materials A and B through the quantitative feeding device. According to the required amount, it is quantitatively introduced into two pulping mixing tanks, and the two basic materials A and B are mixed with water through mechanical stirring to prepare two kinds of slurries with a material-to-water mass ratio of 1:(1-3).

[0032] Using the mud plunger pump in pumping system 1, the A slurry and the B slurry in the slurry mixing tank are pumped out and transported respectively. The volume ratio of the two is 1:1. Mixed to form a quick-setting gun mud slurry for filling the gun holes, the mixed quick-setting gun mud slurry is fed into the plugging pipeline, and the mud pump in the pumping system 2 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com