A passive self-flowing filling method for a carbon dioxide cracking device

A technology of carbon dioxide and liquid carbon dioxide, which is applied in the container discharge method, container filling method, fluid treatment, etc., can solve the problems of complex operation and large capital investment, and achieve the effect of small investment in equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

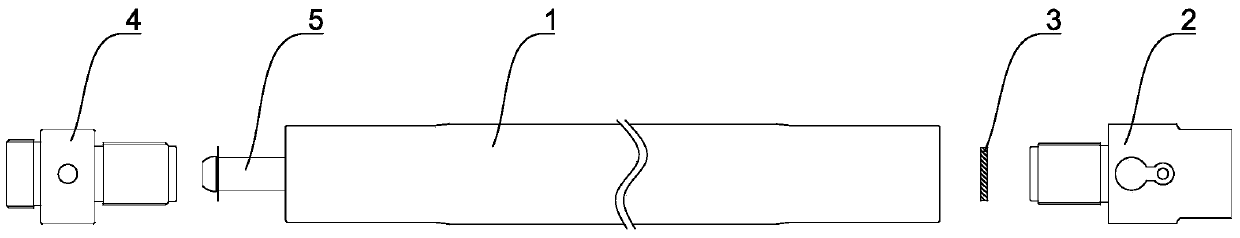

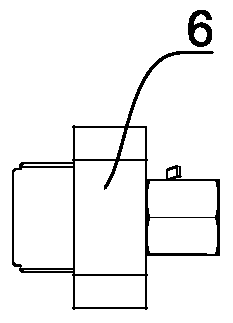

[0027] As a specific embodiment, the present invention provides a passive self-flowing filling method for a carbon dioxide cracking device, wherein the carbon dioxide cracking device includes a cracker main pipe, an energy release head, a burst disc, a filling head, and a heating device , The energy-discharging head is provided with an energy-discharging channel and an energy-discharging hole, the filling head is provided with a filling interface, a filling channel and a thimble, and the heating device is arranged in the main pipe of the cracker. The liquid carbon dioxide tank is a commonly used tank body for containing liquid carbon dioxide. In order to implement the passive self-flowing filling method of the carbon dioxide cracking device of the present invention, the present invention is also provided with a simple head and a valve on the simple head. The filling method includes the following steps:

[0028] 1. Screw the filling head on the filling end of the main pipe of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com