Production method of environment-friendly density board

A production method and technology for MDF, which are applied in the pretreatment of molding materials, household appliances, manufacturing tools, etc., can solve the problems of reducing the strength of MDF and uneven density distribution of MDF, and improve crack resistance and reduce porosity. , the effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

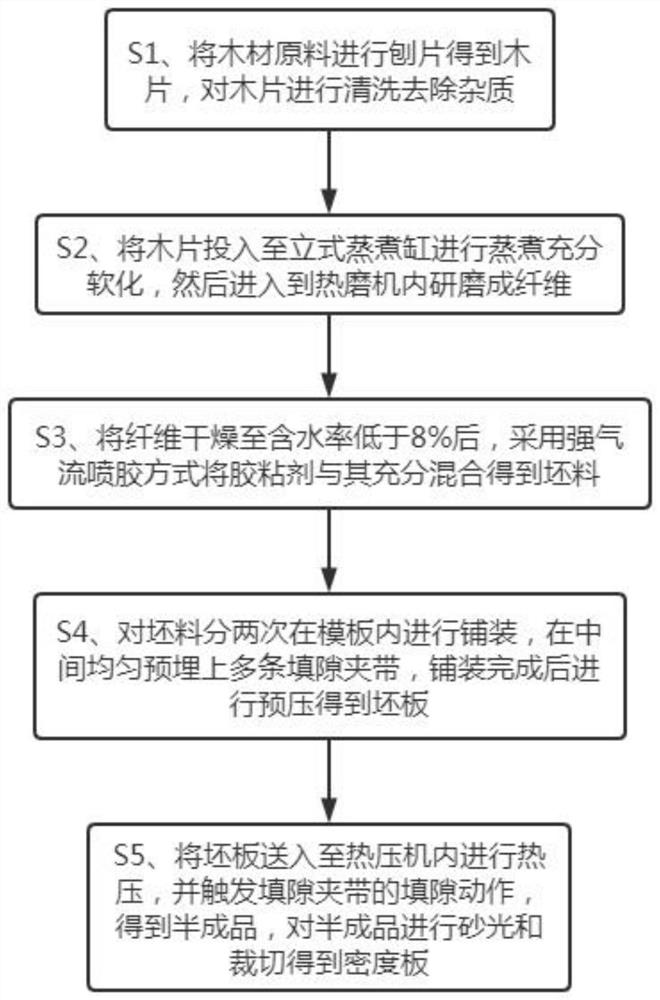

[0043] see Figure 1-2 , a production method of environment-friendly MDF, comprising the following steps:

[0044] S1, the wood raw material is sliced to obtain wood chips, and the wood chips are cleaned to remove impurities;

[0045] S2, put the wood chips into the vertical cooking tank for cooking to be fully softened, and then enter the thermal mill to grind into fibers;

[0046] S3. After drying the fiber to a moisture content of less than 8%, the adhesive is fully mixed with it by means of strong airflow spraying to obtain a blank;

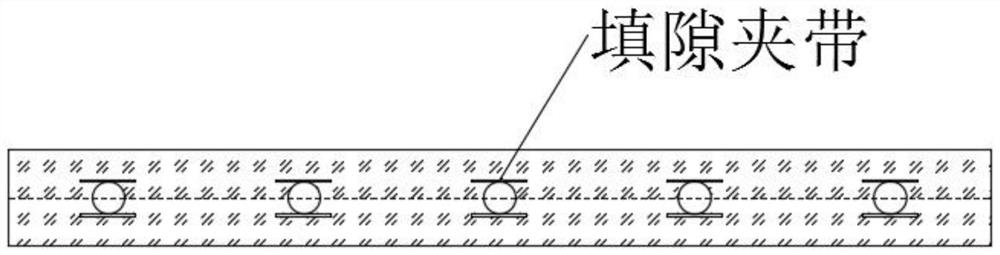

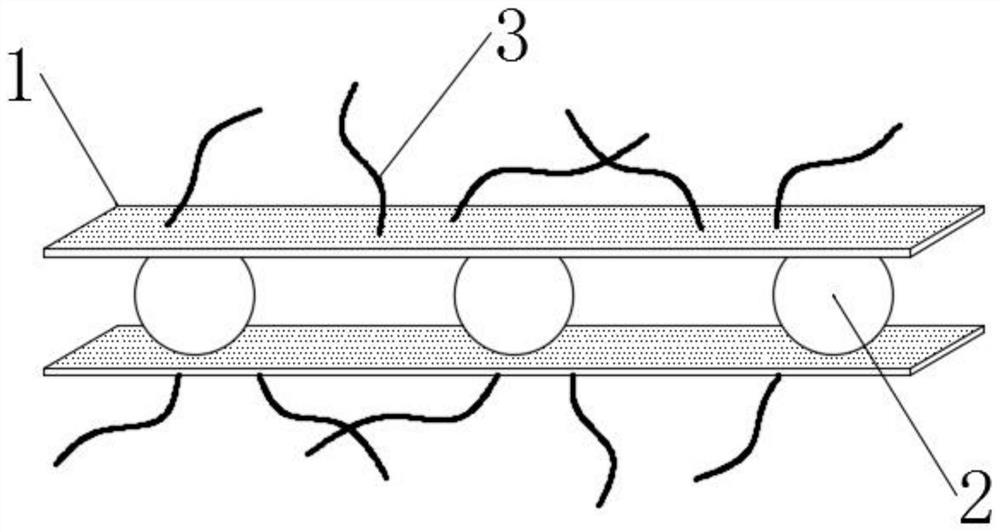

[0047] S4. Pave the blank in the template twice, and evenly pre-embed a plurality of gap-filling entrainments in the middle. After the paving is completed, pre-press to obtain the blank;

[0048] S5. The blank plate is sent into the hot press for hot pressing, and the interstitial action of interstitial entrainment is triggered to obtain a semi-finished product, and the semi-finished product is sanded and cut to obtain a density board.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com