A kind of preparation method of concrete waterproof compacting agent

A waterproof and dense concrete technology, which is applied in the field of building material additive preparation, can solve the problems of reducing concrete strength and waterproof performance, and achieve the effects of enhanced strength and waterproof performance, improved strength and waterproof performance, and stable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

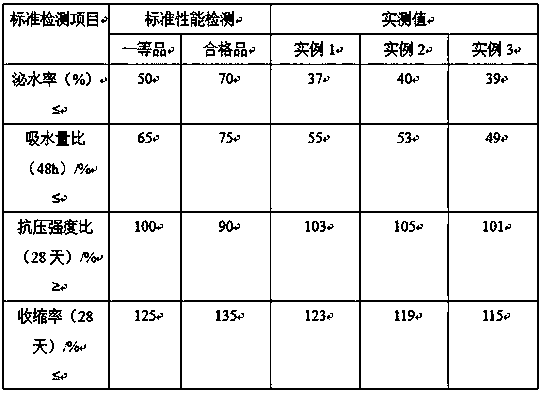

Examples

example 1

[0019] First, weigh 400g of glycine and add it to a beaker containing 800mL of water. Move the beaker into a digital thermostat and speed measuring magnetic stirrer. Stir and dissolve at a temperature of 70°C and a speed of 350r / min for 20 minutes to obtain a glycine mixed solution. 500mL glycine mixed solution was added to a three-necked flask with a thermometer and a reflux device, and a 15% sodium hydroxide solution was added to the flask to adjust the pH to 10.5, then the flask was moved into a water bath, and the temperature of the water bath was controlled to 60℃ Then, add 60mL epichlorohydrin dropwise to the flask and control the dropping rate to 5mL / min. After the addition is complete, keep the temperature and stir for 3h. After the reaction is over, add 10% hydrochloric acid to the flask to adjust the contents of the flask. After the pH is 7.5, the product is obtained, and the product is allowed to stand for liquid separation to obtain the lower layer liquid. The lower ...

example 2

[0021] First, weigh 300g of glycine and add it to a beaker containing 700mL of water, move the beaker into a digital constant temperature and speed measuring magnetic stirrer, stir and dissolve at a temperature of 60°C and a rotational speed of 300r / min for 15 minutes to obtain a glycine mixed solution. 400mL glycine mixed solution was added to a three-necked flask with a thermometer and a reflux device, and a 15% sodium hydroxide solution was added to the flask to adjust the pH to 10.2, then the flask was moved into the water bath, and the temperature of the water bath was controlled to 50℃ Then, add 50mL epichlorohydrin dropwise to the flask and control the dropping rate to 3mL / min. After the addition is complete, heat and stir the reaction for 2h. When the reaction is over, add 10% hydrochloric acid to the flask to adjust the contents of the flask. After the pH is 7.3, the product is obtained, and the product is allowed to stand for liquid separation to obtain the lower layer...

example 3

[0023] First, weigh 350g of glycine and add it to a beaker containing 750mL of water. Move the beaker into a digital constant temperature and speed measuring magnetic stirrer. Stir and dissolve at a temperature of 65°C and a speed of 320r / min for 17 minutes to obtain a glycine mixed solution. 450mL of glycine mixed solution was added to a three-necked flask with a thermometer and reflux device, and a 15% sodium hydroxide solution was added to the flask to adjust the pH to 10.3, then the flask was moved into a water bath, and the temperature of the water bath was controlled to 55℃ Then, add 55mL epichlorohydrin dropwise to the flask and control the dropping rate to 4mL / min. After the addition is complete, heat and stir the reaction for 2h. When the reaction is over, add 10% hydrochloric acid to the flask to adjust the contents of the flask. After the pH is 7.4, the product is obtained, and the product is left for liquid separation to obtain the lower layer liquid. The lower layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com