Food processing type oyster sauce filling head

A technology of food processing and filling head, applied in the field of filling head device, food processing oyster sauce filling head, can solve the problems of filtering and filling efficiency, affecting the quality of finished products, slow liquid flow, etc. Filling effect, improve filling efficiency, increase the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

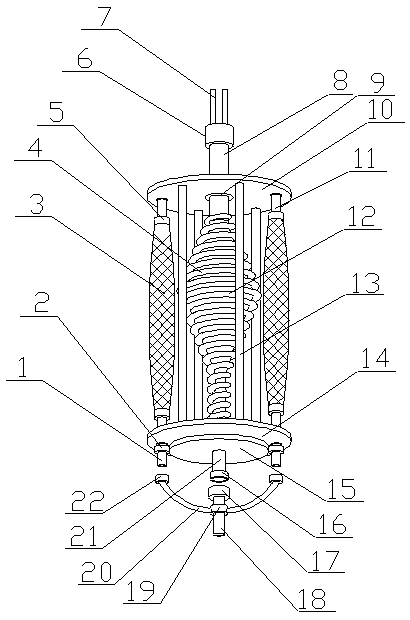

[0022] A food processing oyster sauce filling head of the present invention is realized in this way. When in use, when food processing is filling oyster sauce, the present invention is first installed in the filling head of the filling equipment, and the heating tube (7) The two ends of the pipe are respectively connected to the external hot water pipeline, and then the external motor is connected to the connecting sleeve (6). The hot water enters the heating pipe (7) through the liquid inlet of the heating pipe (7), and along the heating pipe (7) Spiral flow, transfer heat to the heating tube (12), and finally flow back to the external hot water pipeline from the outlet of the heating tube (7), the external motor works, and drives the hollow rotating rod through the connecting sleeve (6) (8) Turn, the hollow rotating rod (8) drives the heating cylinder (12) to rotate, the heating cylinder (12) drives the spiral blade (4) to rotate, and drives the support rod (21) to rotate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com