Powder cavity filling device

A technology of filling device and cavity, which is applied in the field of powder cavity filling device, to achieve stable working speed and filling effect, and to ensure the effect of working speed and filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

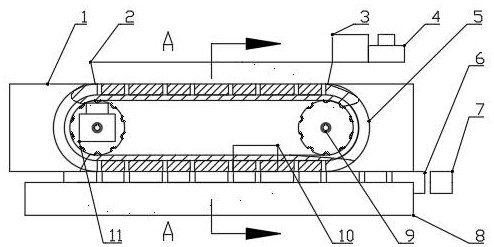

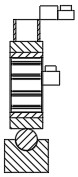

[0022] A powder cavity filling device, including a filling device and a transport device;

[0023] Described packing device comprises sealing block 1, conveyer belt 5, hopper 2, motor A4 and vibrating device 3, is provided with mounting groove on the side of described sealing block 1, two groove walls of described mounting groove are connected with sealing block respectively The top surface and the bottom surface of 1 are connected, the bottom of the installation groove is connected with the side of the sealing block 1, the outer wall of the conveyor belt 5 is in contact with the groove wall of the installation groove, and pulleys 9 are provided at both ends of the inner wall of the conveyor belt 5. The pulley 9 cooperates with the inner wall of the conveyor belt 5, a motor B11 is installed on the side of the pulley 9, the pulley 9 is electrically connected with the motor B11, and the outer wall of the conveyor belt 5 is provided with several evenly spaced cavity holes. The bo...

Embodiment 2

[0028] A specific implementation description is made for the operation mode in Embodiment 1.

[0029] Such as figure 1 As shown, in the present invention, a sensor 10 is arranged on the base 8, which can detect whether the cavity hole on the conveyor belt 5 corresponds to the cavity between the two bars, and when there is a deviation, the motor B11 is used to control the belt. Wheel 9 carries out speed regulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com