A method of filling and supporting beside gob-side entry retaining in thin coal seam

A thin coal seam and gob-entry technology, which is applied to filling materials, earth cube drilling, mining equipment, etc., can solve the problems of increased workload and construction difficulty, reduce auxiliary transportation costs, simple filling process, and good roof connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art understand the present invention more clearly, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

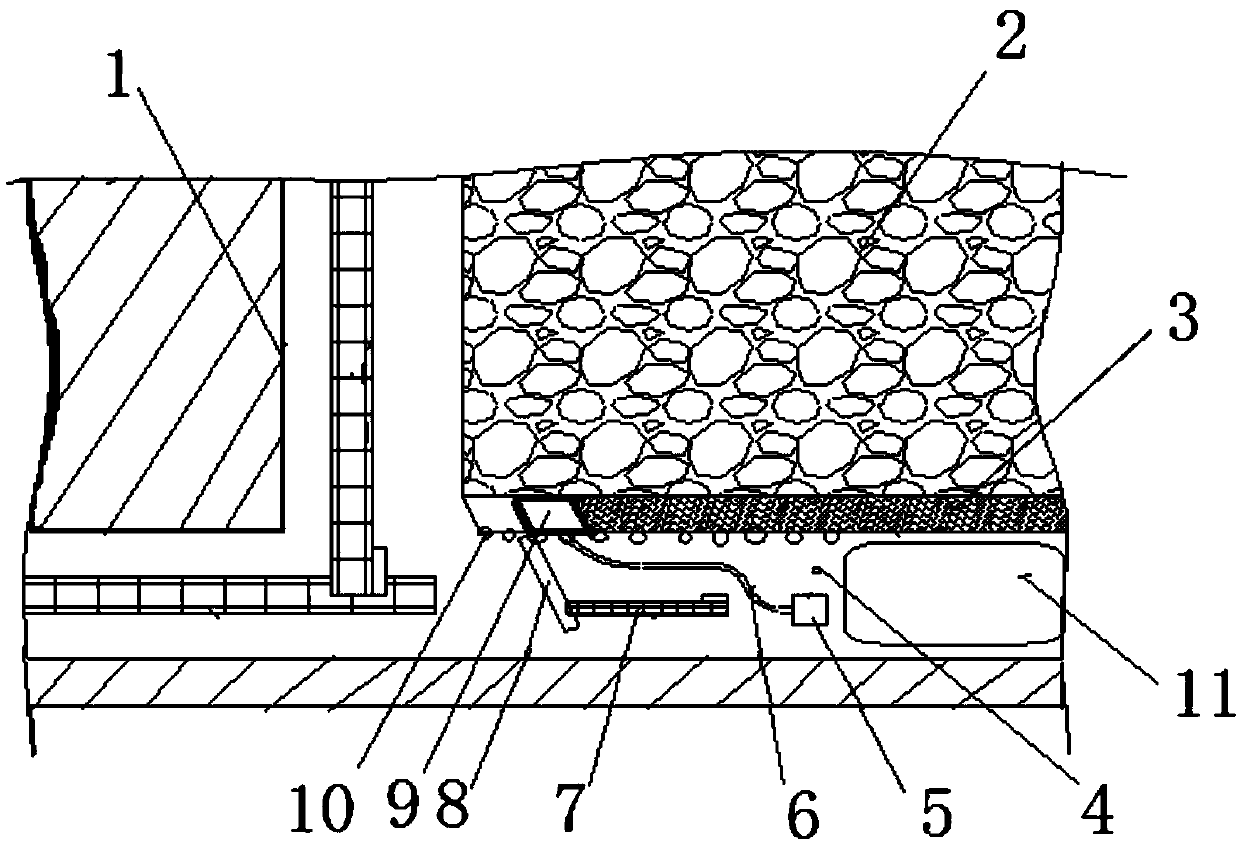

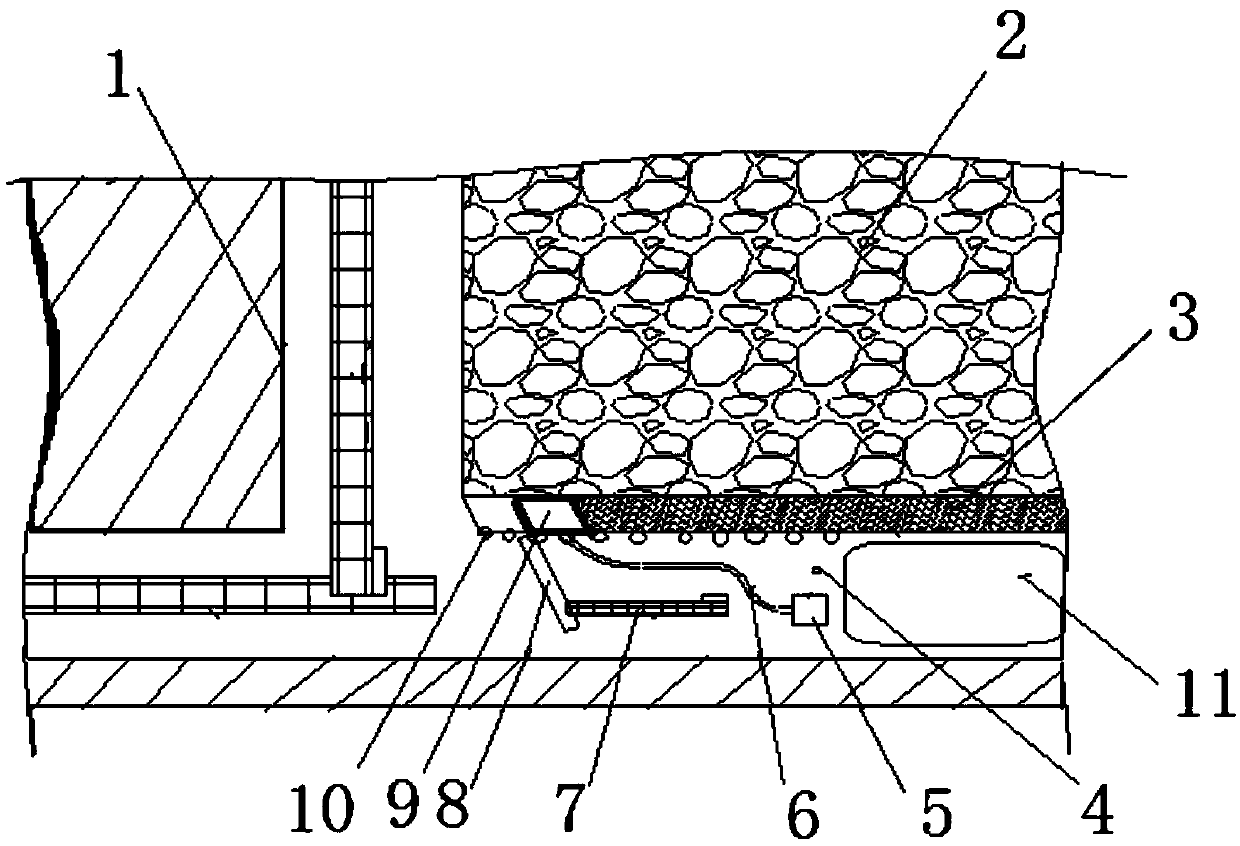

[0027] Such as figure 1 figure 2 As shown, a thin coal seam gobside filling and support method includes the following steps:

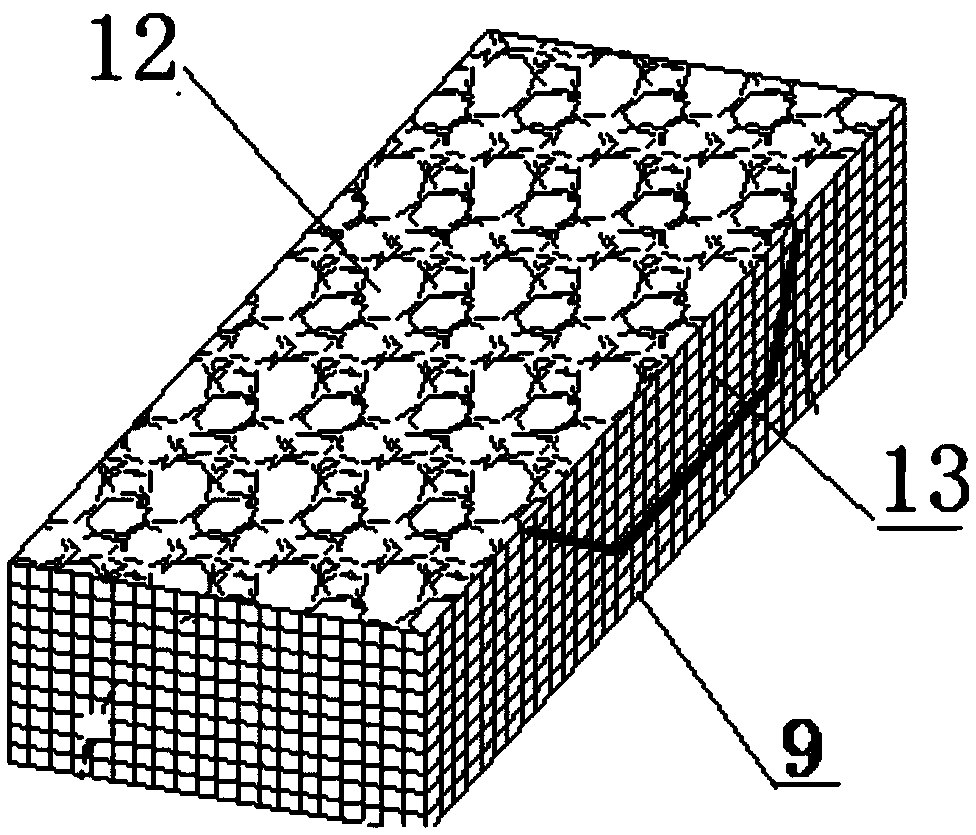

[0028] The first step: as the coal mining face advances, a row of single hydraulic props 10 are erected at the side of the goaf 2 behind the coal mining face 1 to serve as a temporary support; After reaching a filling step in area 2, lay a metal mesh on the design position of the filling wall 3, so that the metal mesh forms a metal cage with a length equal to the filling step, a width equal to the width of the filling wall, and a height close to the roof. body 9, and leave a gap 13 of a certain height on the side of the metal mesh box body 9 facing the gob-side entry, and then hang a woven bag that can bleed on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com