Filling roof-contacted method

A backfill and empty roof technology, which is applied in the fields of backfill, earth-moving drilling, directional drilling, etc., can solve the problems of subsidence and tensile failure of stope roof, low roof connection rate, roof caving, etc., and achieve the effect of roof connection. Good, high connection rate, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

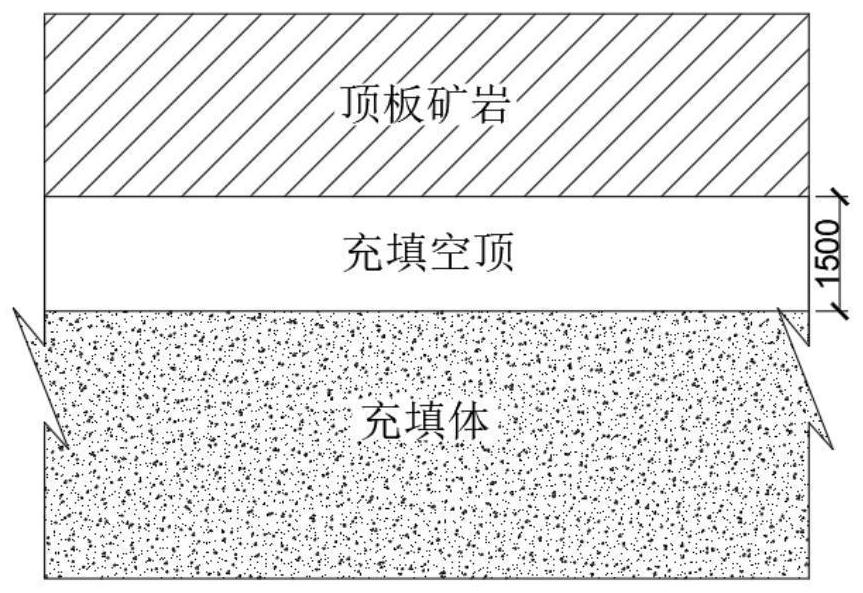

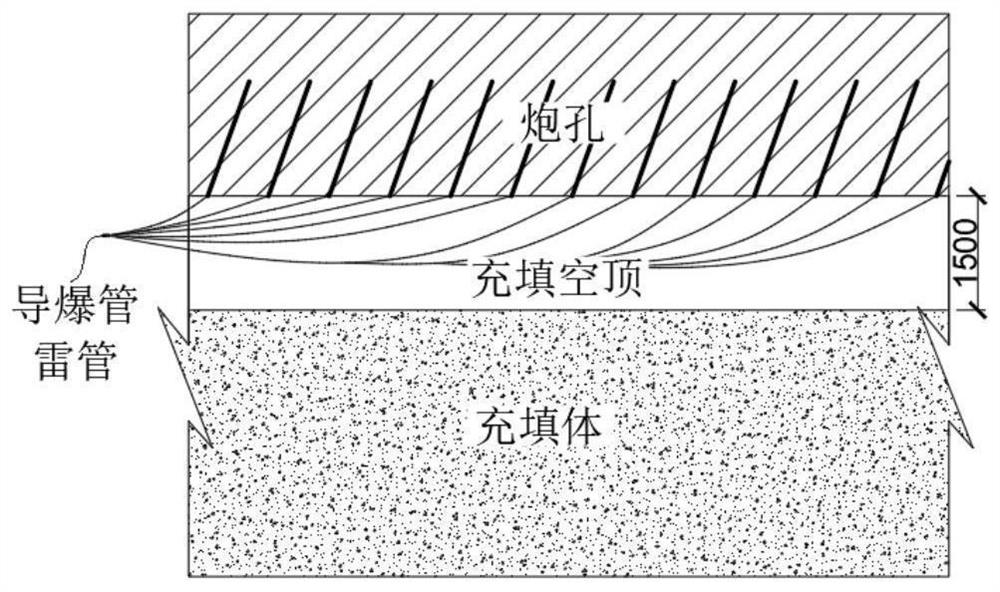

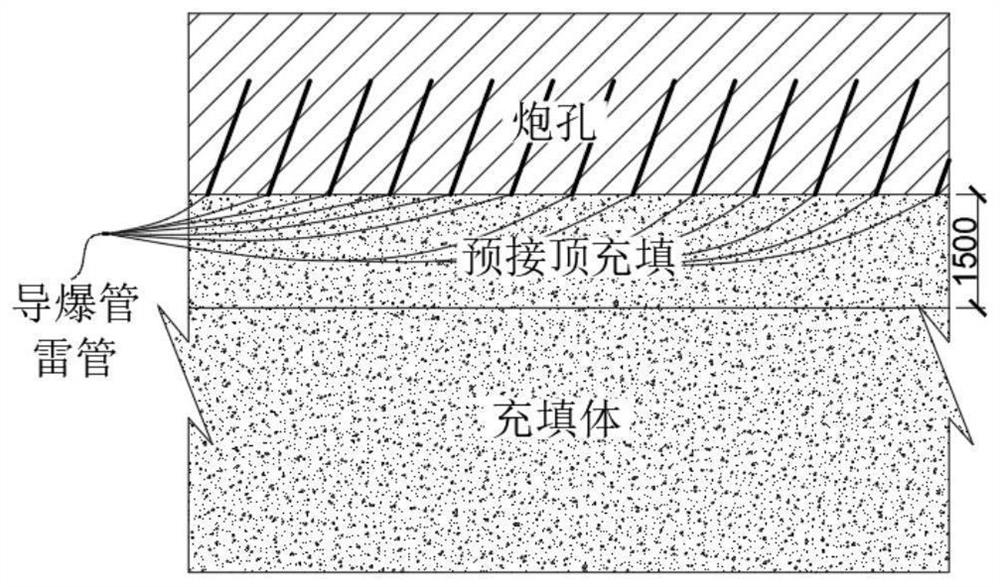

[0019] Figure 1-Figure 4 Reflecting the steps that the present invention implements, it can be seen from the figure that this embodiment includes the following steps:

[0020] Step (1) see figure 1 , after the stope mining is completed, the filling operation is carried out, and when the filling is about 1.5-2m away from the roof of the stope, the filling is stopped; the reserved height of the head is convenient for the subsequent steps, so the height of the head can be satisfied. On the basis of carrying out follow-up operations, the height dimension should be as small as possible, and what is selected in this embodiment is 1.5m.

[0021] Step (2) see figure 2 , after the filling body in step (1) is solidified, use a shallow hole drilling rig to drill forward-inclining parallel holes on the roof. The blast hole spacing is larger than that of normal stope shallow hole blasting, and can be selected in the range of 0.8m-1.5m. It is preferably 1.2m, and then charged and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com